8

3.4 Wire Loading and Threading

Turn machine power switch to the OFF(“0”)position before working inside the wire feed enclosure.

Make sure that the wire feed drive roll and the contact tip of the gun match the diameter and type of

wire used.

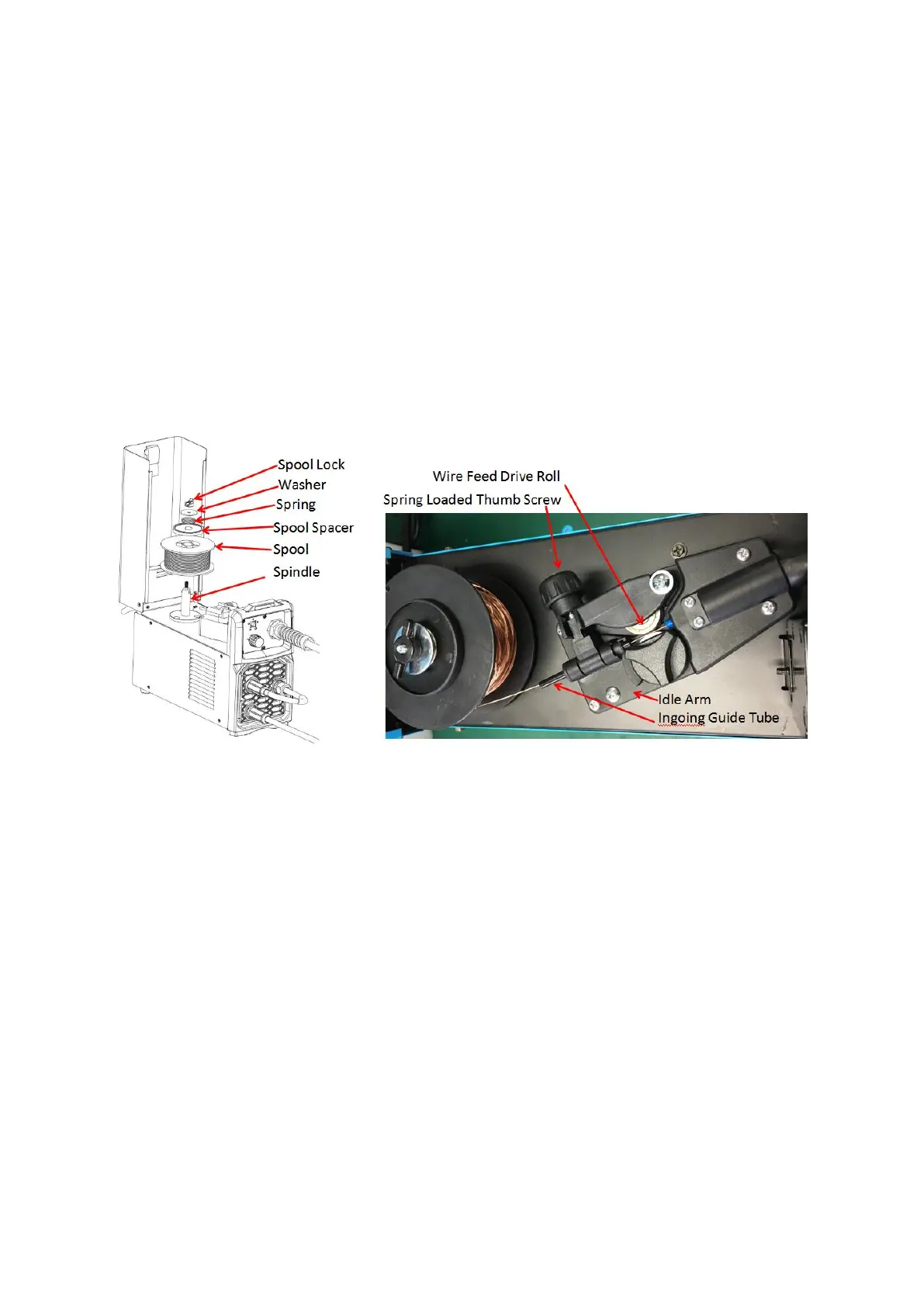

Installation of Wire Spool

1) Push the spool onto the spindle so that the wire deeds off the bottom of the spool, toward the

drive roll.

2) Push the spool spacer onto the spindle, against the spool.

3) Slide the spring onto the spool, them press on the spool lock, turning it clockwise to lock the

spool assembly onto the spindle.

Wire Threading Details

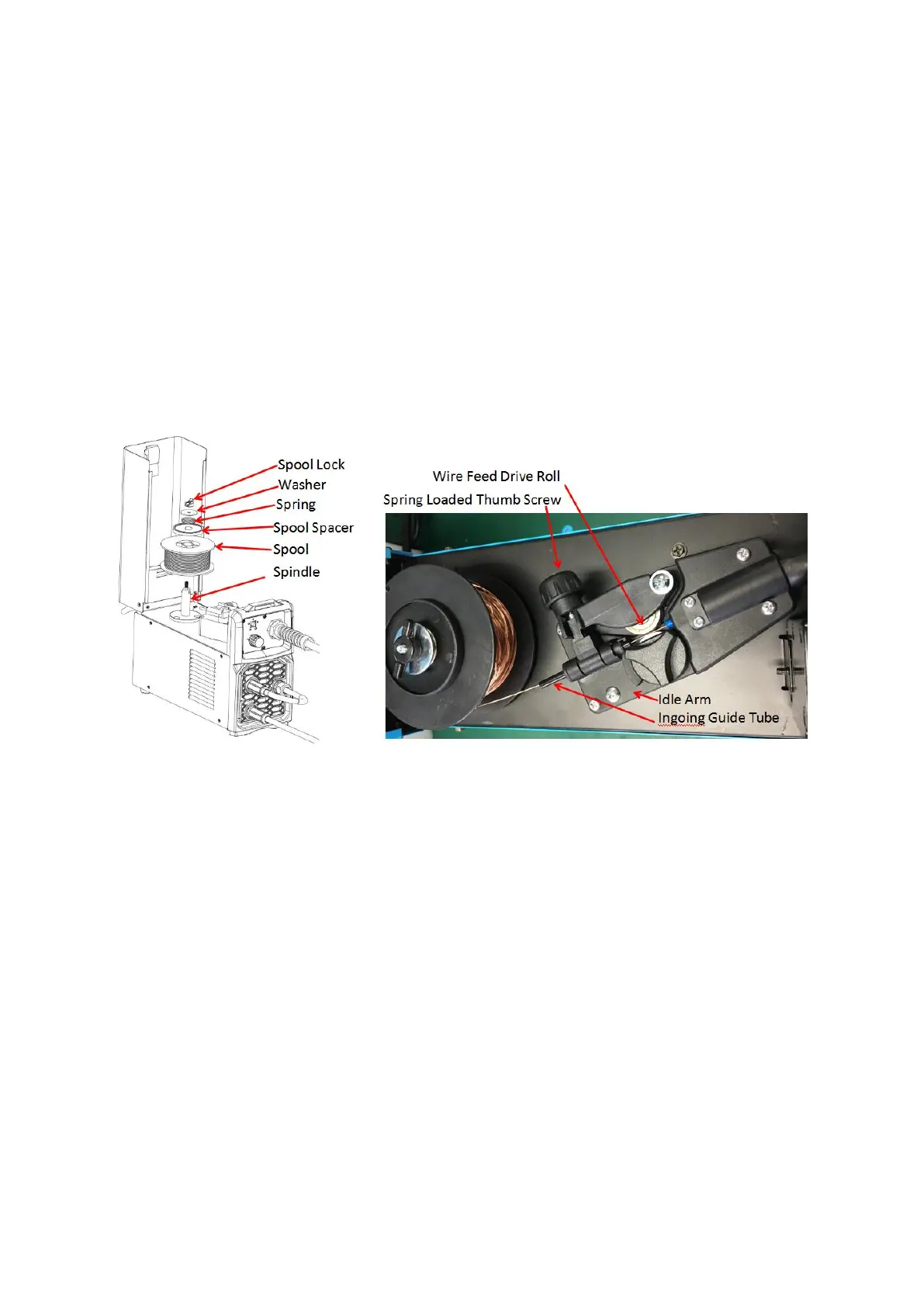

1) Release the spring loaded thumb screw and rotate the idle roll arm away from the wire deed

drive roll. Ensure that the visible, stenciled size on the drive roll side facing you matches the wire

size being used.

2) Carefully detach the end of the wire from the spool. Maintain tension on the wire to prevent the

spool from unwinding and do not release the wire until after step8.

3) Cut the bent portion of wire off and straighten the first 4”(100mm).

4) Thread the wire through the incoming guide tube, over the drive roll, and into the gun liner.

5) Close the idle roll arm and turn down the thumbscrew until the idle roller presses down firmly on

the wire. (Now you may release the welding wire ). Make sure the wire is positioned in the groove of

the lower drive roll.

6) The spring loaded thumbscrew on the idle roll arm adjusts the pressure on the wire .Adjust

pressure by turning the thumbscrew to prevent spool overrun, but still allow smooth and easy wire

deeding. Start with the pressure set to an intermediate value. Readjust, if necessary.If the drive roll

slips while feeding wire , the pressure should be increased until the wire feeds properly.

Digital Welder Expert, Know You More

https://www.arccaptain.com

Loading...

Loading...