22

5) Observe all Safety Guidelines detailed throughout this manual

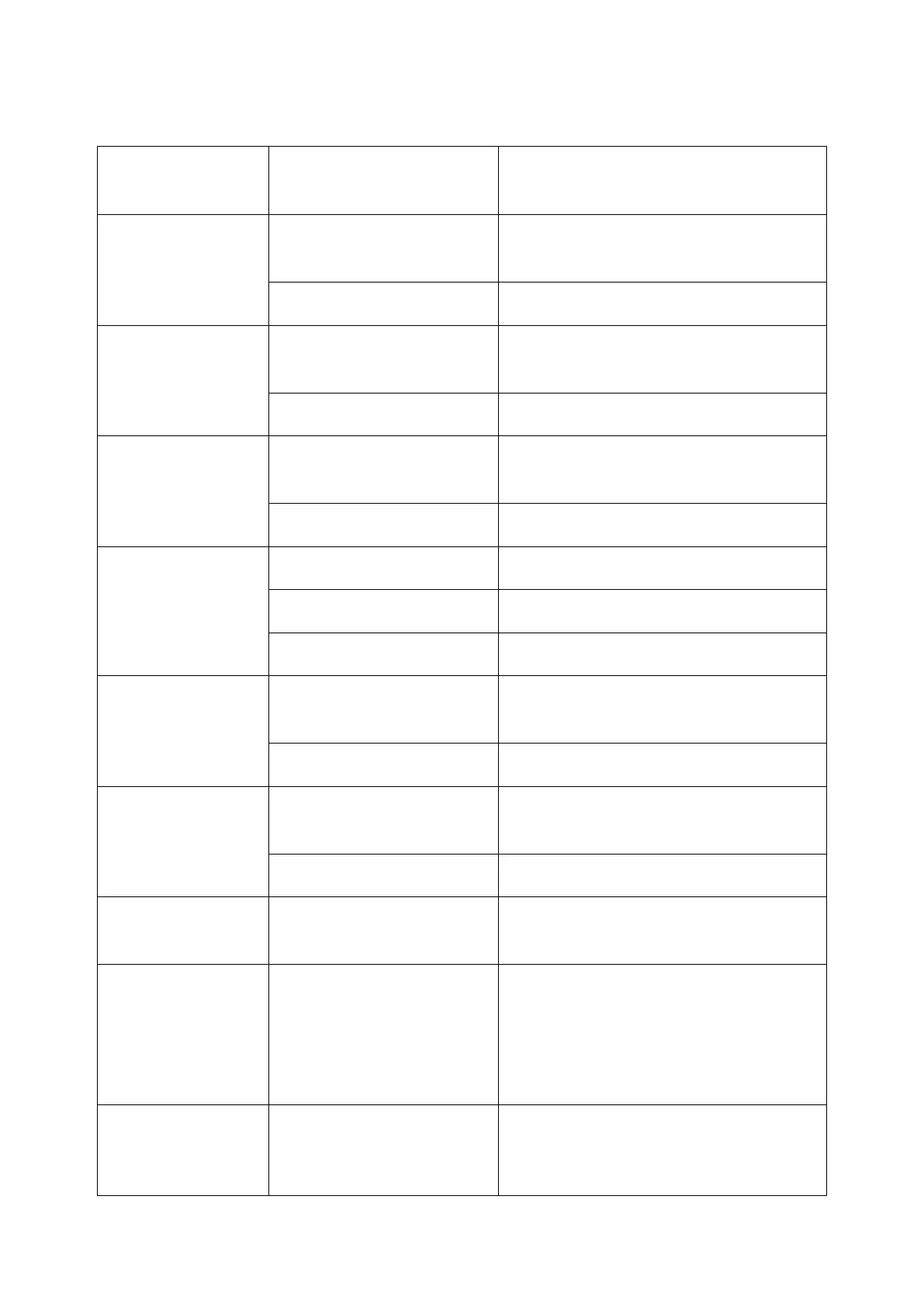

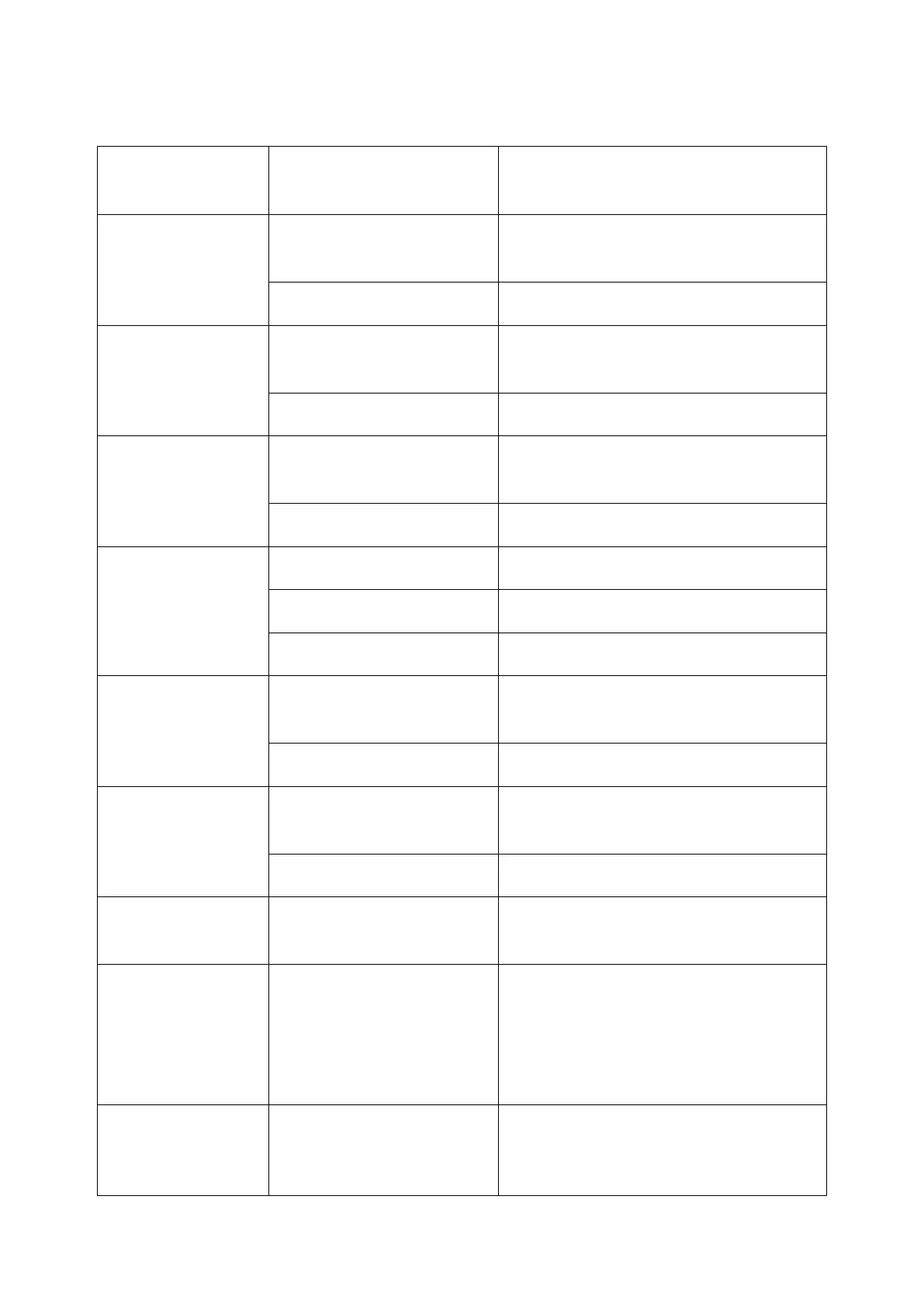

Problem

(symptoms)

Possible areas of

mis-adjustment

Recommended course of action

Bead is too

thick(intermittently)

Travel speed is slow and/or

inconsistent

Increase and maintain a constant travel

speed.

Output heat range is too high. Set the knob to low

Bead does not

penetrate base

metal.

Travel speed is inconsistent. Decrease and maintain a constant travel

speed.

Output heat range is too low. Set the knob to high

Wire sputters and

sticks to workpiece

The wire is damp. Change to dry wire.Be sure wire is stored

in a dry location

Wire feed speed is too fast. Reduce wire feed speed.

Edge of weld has

ragged depressions

Travel speed is too fast. Reduce travel speed.

Wire feed speed is too fast. Reduce wire feed speed.

Output heat range is too high Set the knob to low

There is no current

after turning on the

machine.

The power cord is not well

connected.

Reconnect the power cord.

The welding machine fails. Ask professionals to check.

The fan does not

work during welding.

The power cord for the fan is

not well connected.

Reconnect the power cord for the fan.

Auxiliary power fails. Ask professionals to check.

The overheating

indicator is on.

The overheating protection

circuit works.

It can be recovered after the machine cools

down.

There is no response

when pushing the

torch trigger and the

alarm indicator does

not illuminate.

The torch trigger fails. Repair or replace the welding torch.

When the torch

trigger is pushed,

there is gas output,

The earth cable is not well

connected with the

workpiece.

Reconnect it.

Digital Welder Expert, Know You More

https://www.arccaptain.com

Loading...

Loading...