12

B. Operation for TIG function

1) power switch

Turn on the power switch on the back panel and fan starts rotating; panel display is normal and power

supply indicator is light on; welder is successfully started.

2) TIG available:

Connect well the argon cylinder and turn on cylinder valve; adjust the flow meter to the according value;

Connect welding torch and earth clamp;

Pull the torch trigger and solenoid valve starts working; there will be argon out, also HF discharging at

the same time.

Please set welding current according to workpiece thickness.

Keep the distance between torch tungsten and workpiece at 2-4mm/0.08-0.16in; pull the torch trigger

and welder’s HF discharging noise will disappear as long as arc is successfully ignited; welding can be

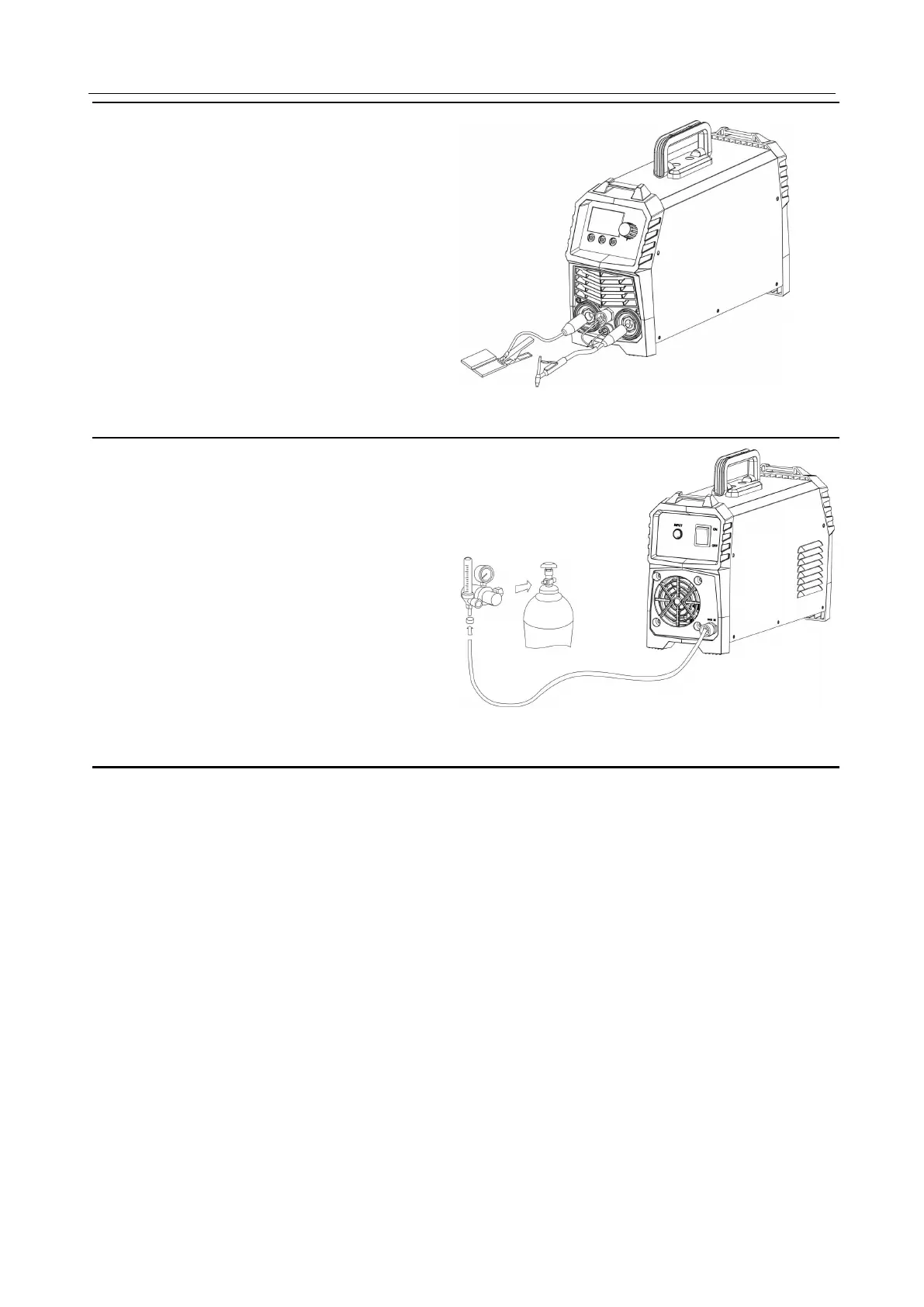

4. Insert the quick plug on the earth cable into

the “+” quick socket on the machine panel, and

tighten it clockwise. Clamp the workpiece with

the earth clamp at the other end of the earth

cable. (See Pic 9.)

Pic 9 Installation of Earth cable

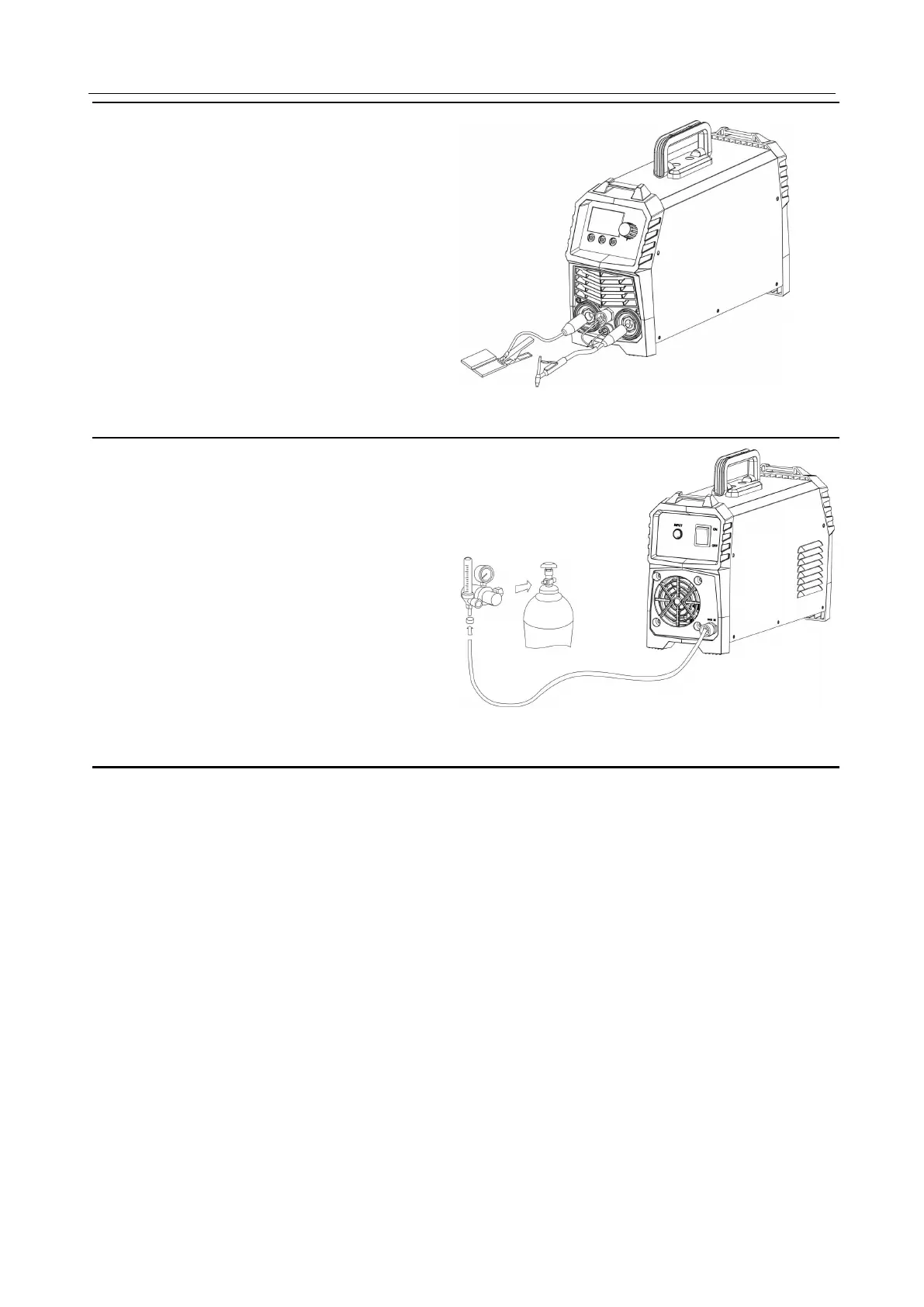

5. Gas connection: connect argon tube with

welder back panel’s brass mouthpiece tightly.

Air supply passage should include argon

decompressed flowmeter, gas hose; please use

a hose clamp or other fixing items to crew the

hose connection part so that to avoid poor

welding spot protection which is caused by gas

leakage or air admission. (Pic 10)

Pic 10 Gas connection

Digital Welder Expert, Know You More

https://www.arccaptain.com

Loading...

Loading...