13

started;

3) Current regulation

Operators can choose according to welding current per workpiece thickness.(current range:10-200A)

4) Post-flow time

Post-flow time is the time between arc ending and post-flow. Post-time can be adjusted between

1-10seconds.

5) down slope time

:

to adjust the output current down slope time.

6) 2T/4T :select 4T

【

The up- and down-slopes are switched off

】

.

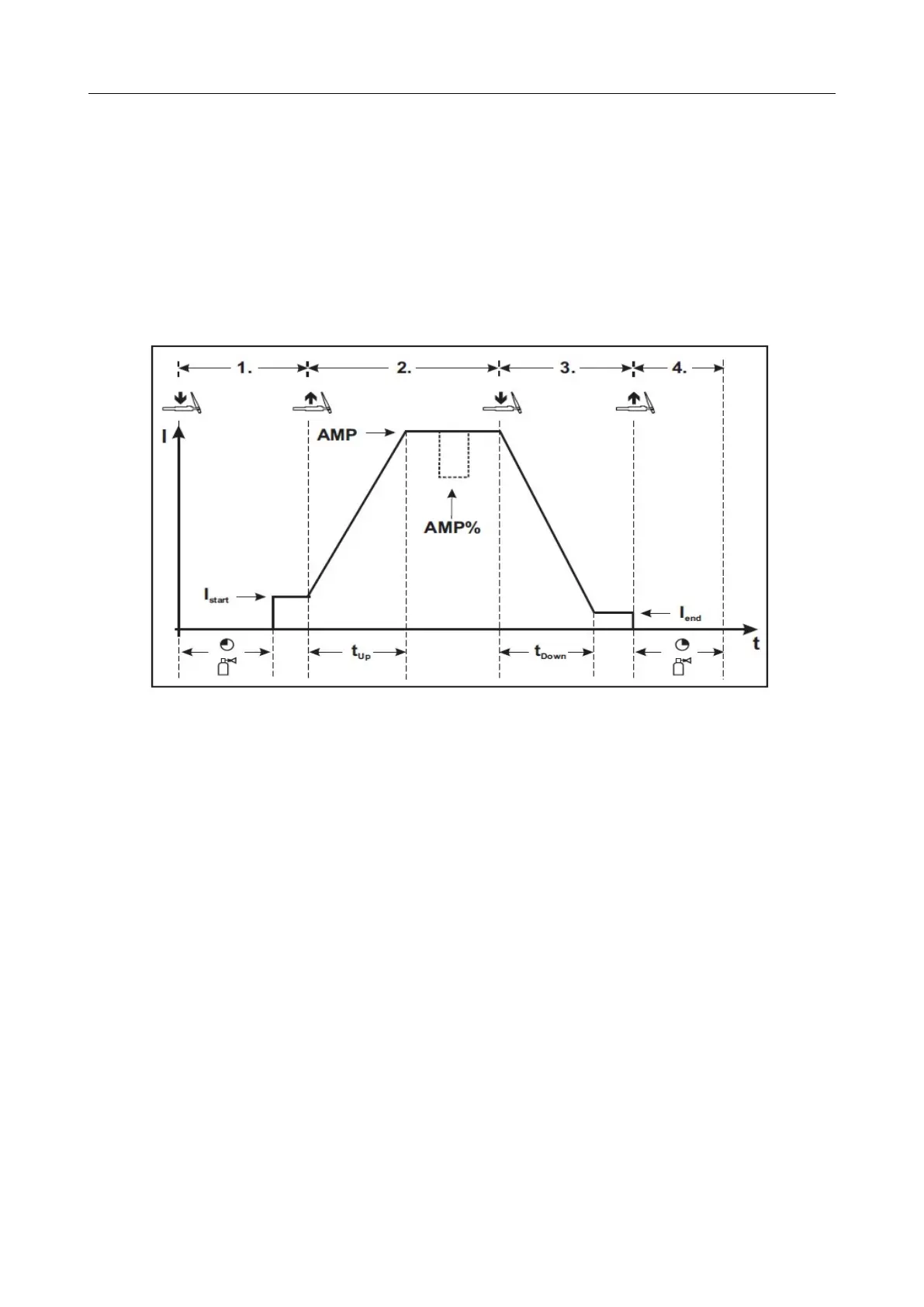

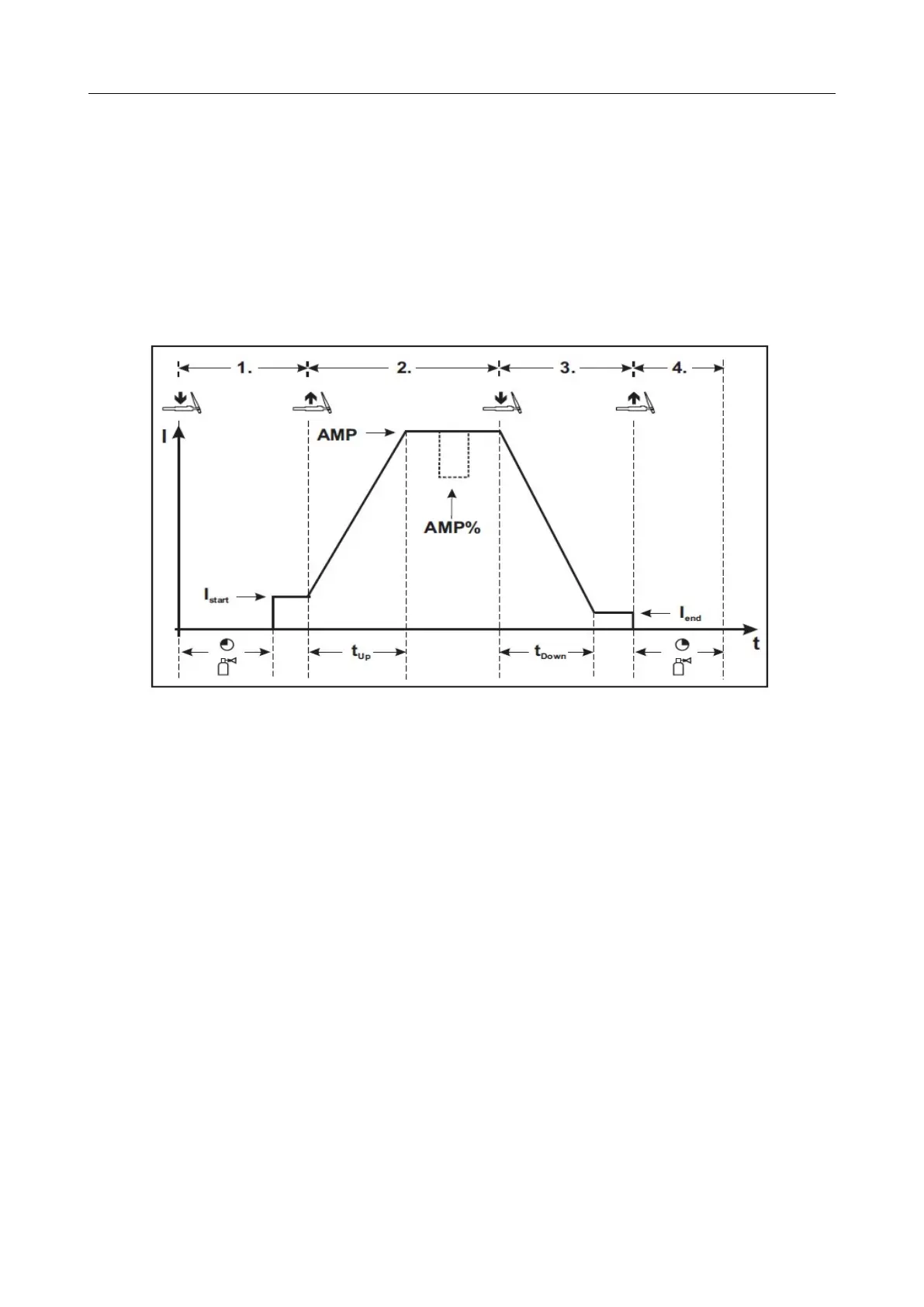

Pic 11 4T welding logic

Step 1

• Press torch trigger 1, there is gas pre-flow time

(

150ms).

• HF ignition pulses from the electrode to the workpiece, the arc ignites.

• Welding current flows and immediately the ignition. HF is switched off.

Step 2

• Release torch trigger 1.

• The welding current increases with the set up-slope time( built-in 0 second) to the main current AMP.

Switching from main current AMP to secondary current AMP%:

Press torch trigger 2 or Tap torch trigger 1 *

Step 3

• Press torch trigger 1.

• The main current drops with the set down-slope time to the end-crater current Iend (minimum current).

Step 4

• Release torch trigger 1, the arc extinguishes.

• The set gas post-flow time begins.

Immediate termination of the welding process in the downslope by releasing torch trigger 1.

Digital Welder Expert, Know You More

https://www.arccaptain.com

Loading...

Loading...