B-5 INSTALLATION B-5

ELECTRIC SHOCK can kill.

Keep the electrode holder and

cable insulation in good condition.

Do not touch electrically live parts

or electrode with skin or wet clothing.

Insulate yourself from work and ground.

Turn the input line Switch on the arcweld

®

machines “Off” before connecting or disconnecting

output cables or other equipment.

For secure electrical connection, the power source

output sockets connecting cable plugs must be

tightened. Damage may occur to the output socket

or welding performance maybe compromised.

To avoid interference problems with other equipment

and to achieve the best possible operation, route all

cables directly to the work. Avoid excessive lengths and

do not coil excess cable.

OUTPUT CONNECTIONS

A quick disconnect system using twist mate cable plugs

is used for the welding cable connections. Refer to the

following sections for more information on connecting

the machine for operation of stick welding(MMAW) or

TIG (GTAW).

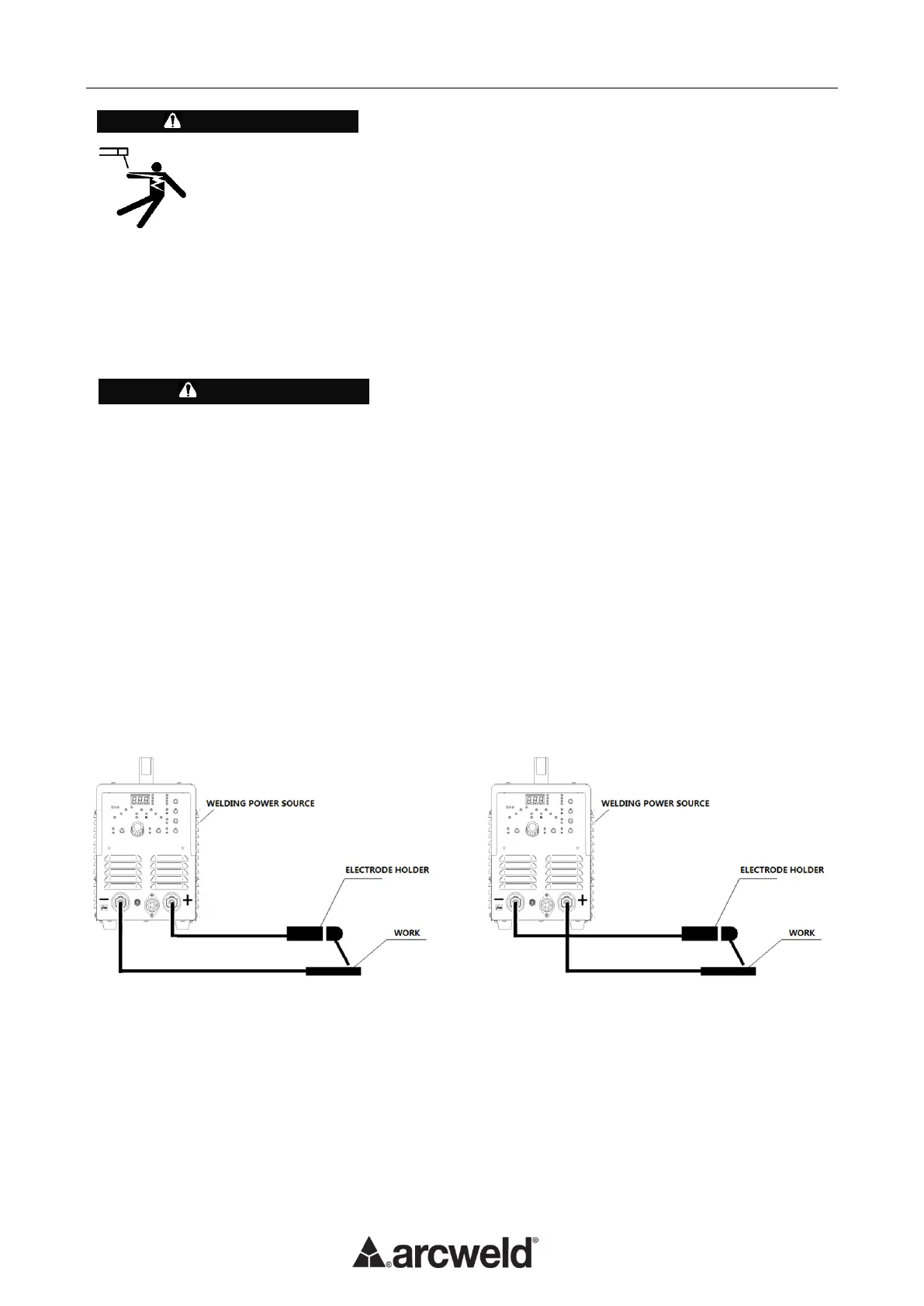

STICK WELDING (MMA)

First determine the proper electrode polarity

for the electrode to be used. Consult the

electrode data for this information. Then

connect the output cables to the output

terminals of the machine for the selected

polarity. Shown here is the connection

method for DC(+) welding. (See Figure B.1)

Connect the welding cable to the (+) terminal

and the work clamp to the (-) terminal. Insert

the connector with the key lining up with the

keyway and rotate approximately 1/4 turn

clockwise. Do not over tighten.

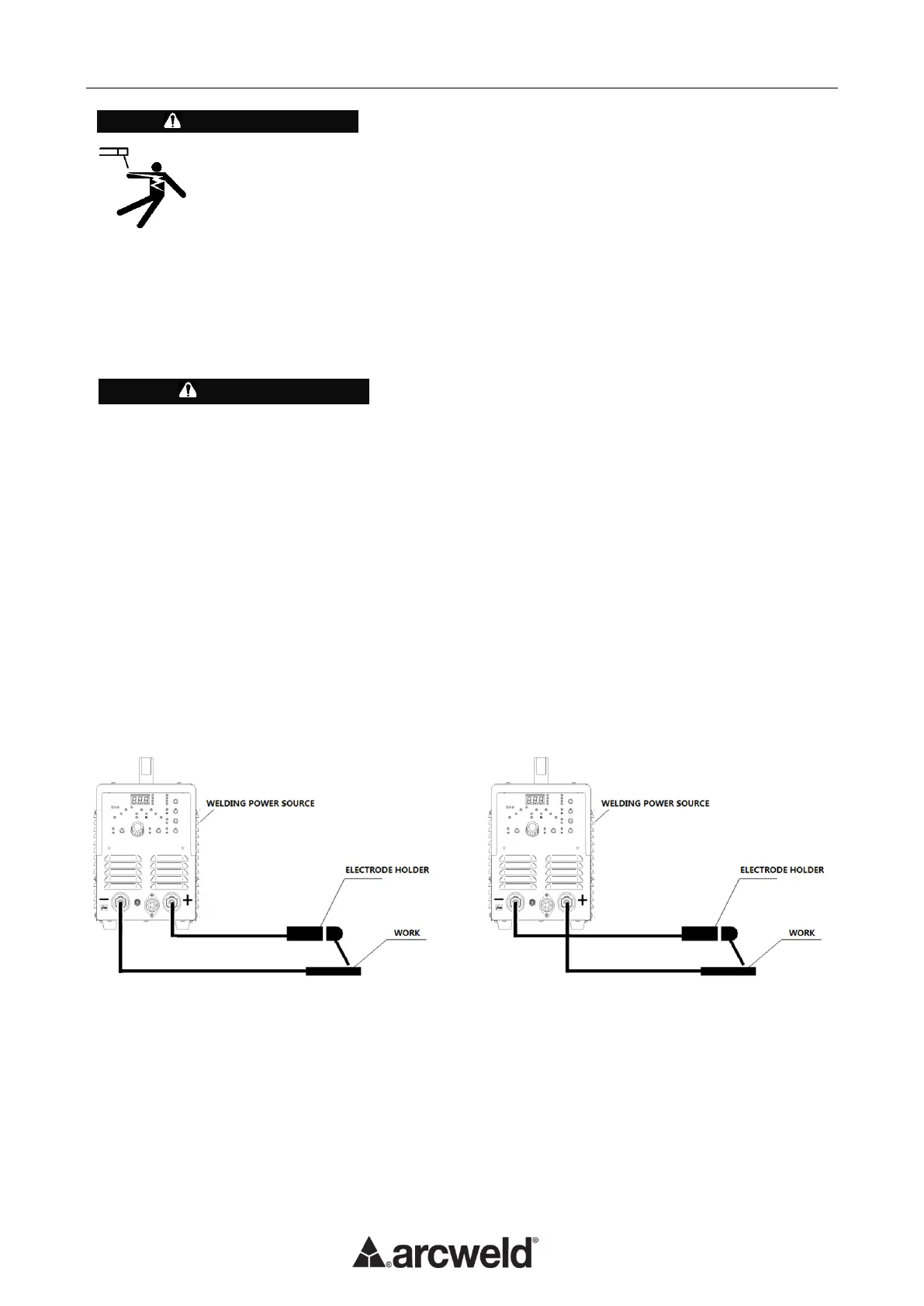

For DC(-) welding, switch the cable

connections at the machine so that the

welding cable is connected to (-) and and

the work clamp is connected to (+). (See

Figure B.2)

Loading...

Loading...