C-7 OPERATION CONTROL AND CONNECTORS C-7

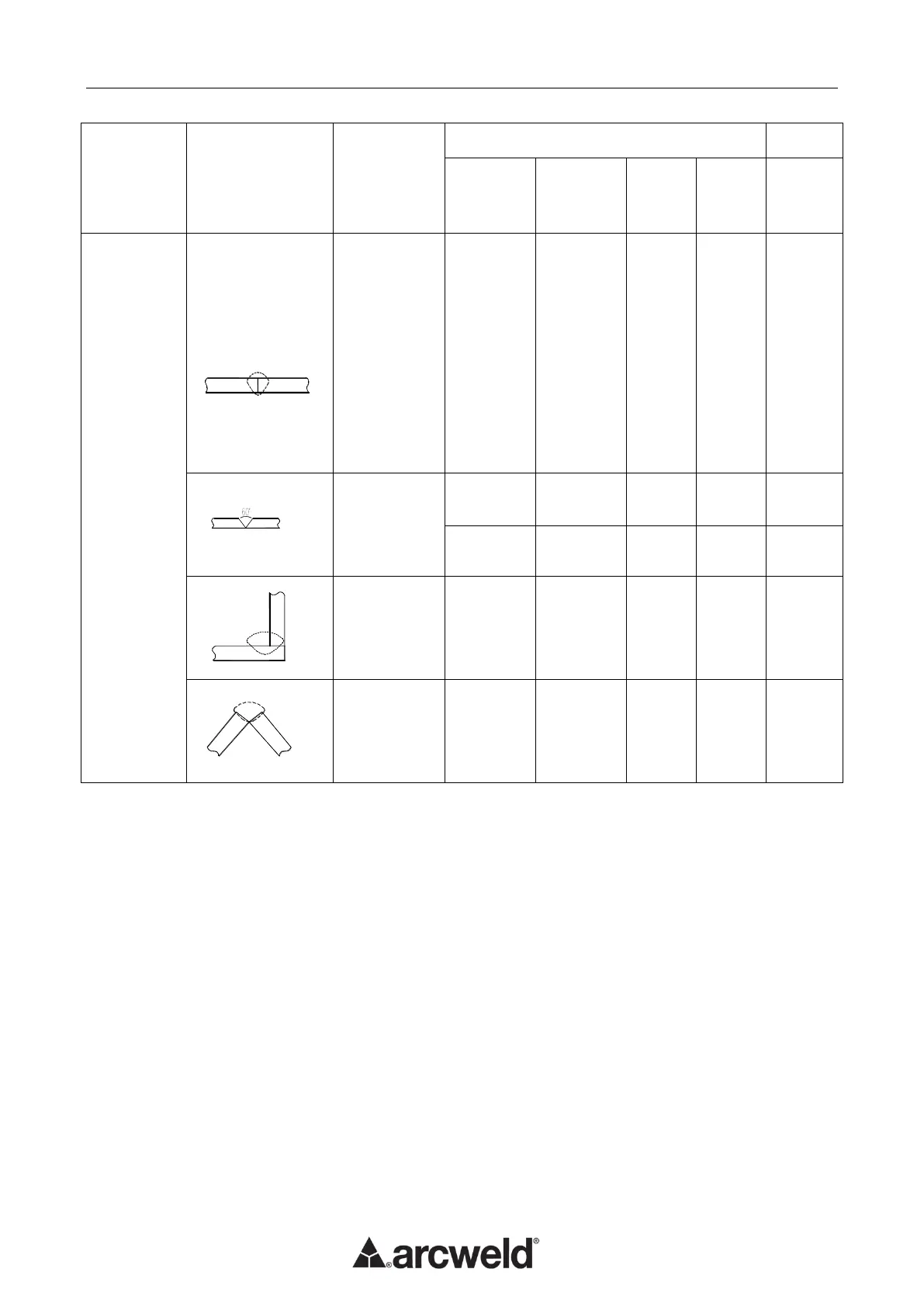

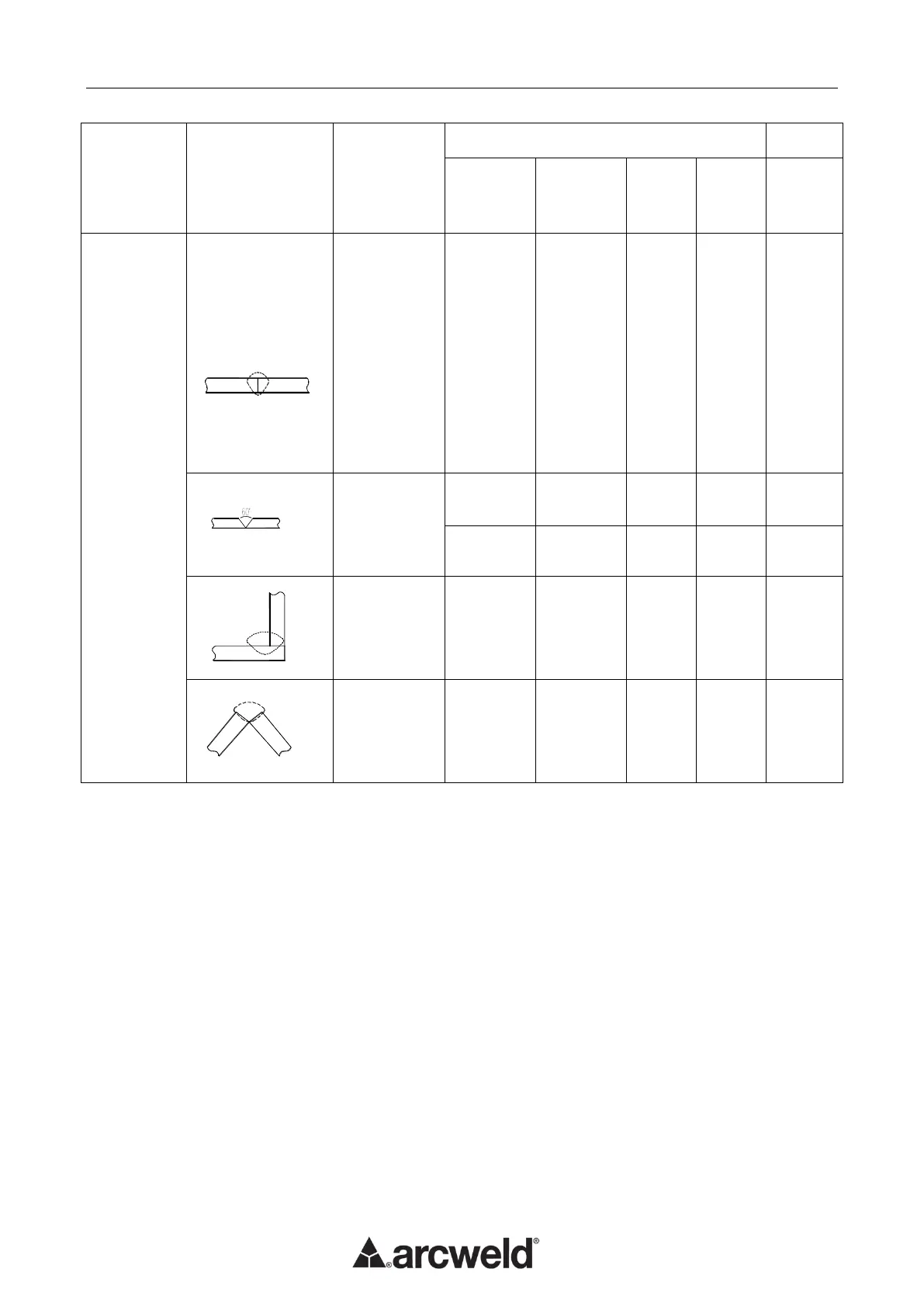

AC TIG / PULSE WELDING TABLE

1.0

1.5

1.5

1.5

3.2

3.0

6.0

1.6

1.6

1.6

1.2

1.2

1.6

1.6

6. AC TIG / MIX OPERATION

PARAMETERS SETTING:

Choose the AC TIG mode, MIX welding function, LIFT/HF , 2T/4T, adjust the preflow time, initial current,

slope up time, peak current,, slope down time, crater current, postflow time, AC frequency, AC balance.

NOTE: AC welding 0.3s+DC welding 0.2s, without pulse function.

7. SPOT OPERATION

PARAMETERS SETTING:

Choose the SPOT mode, adjust the preflow time, slope up time(spot welding time), peak current, slope down

time.

Note: In this mode, the machine operates in HF and 2T only.

Loading...

Loading...