5-3. Normal Display Operations and Functions

■ Normal display functions

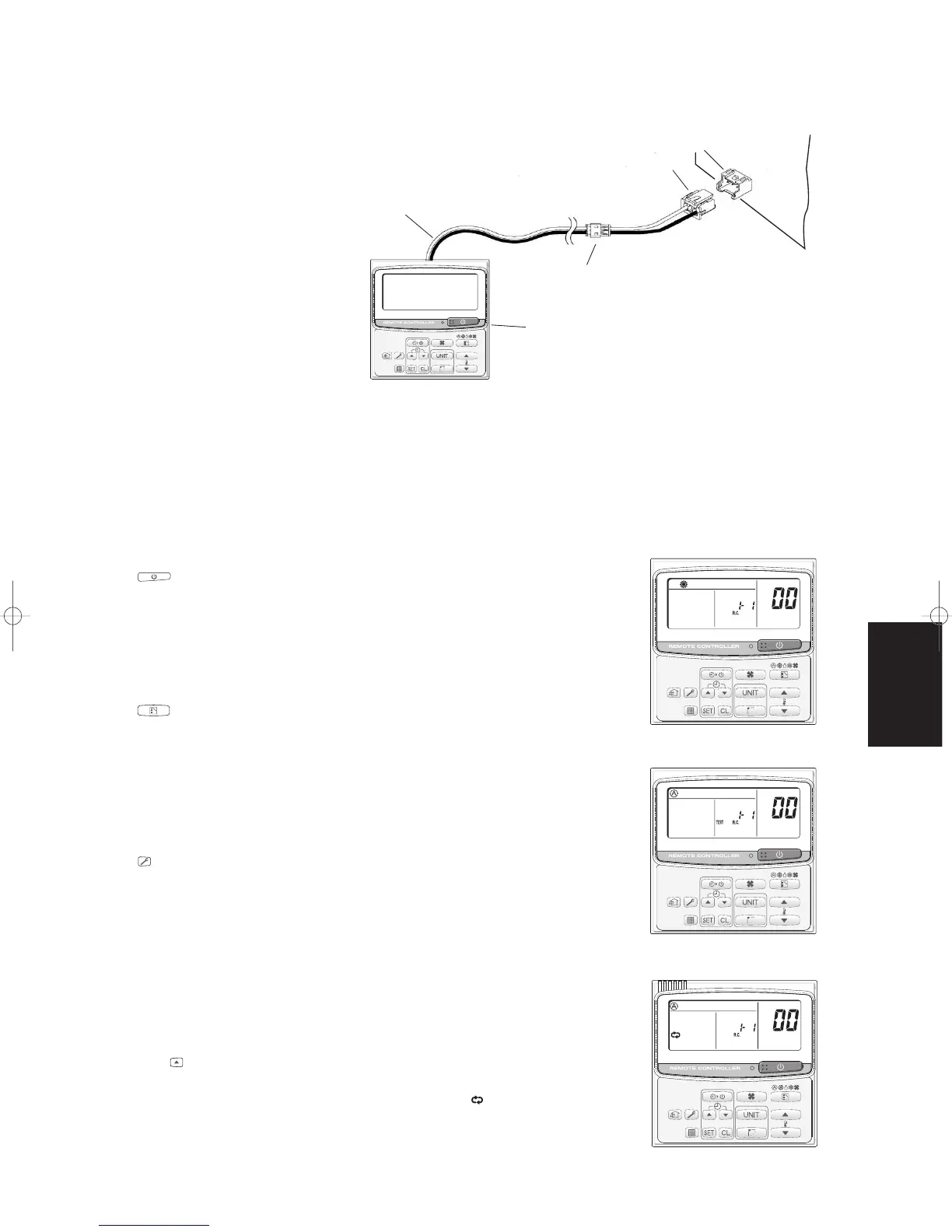

• Connect the special service checker wiring to the outdoor unit PCB.

The connection is shown in the figure below.

* It is not necessary to disconnect the communications line in the inter-unit control wiring if it has already been connected at

this time.

* Settings modes 1 and 2 can be used even when the outdoor unit is independent (when 1 maintenance remote controller is

connected to 1 outdoor unit and automatic address setting for the indoor units has not been completed).

* Displays the overall system status for that refrigerant system.

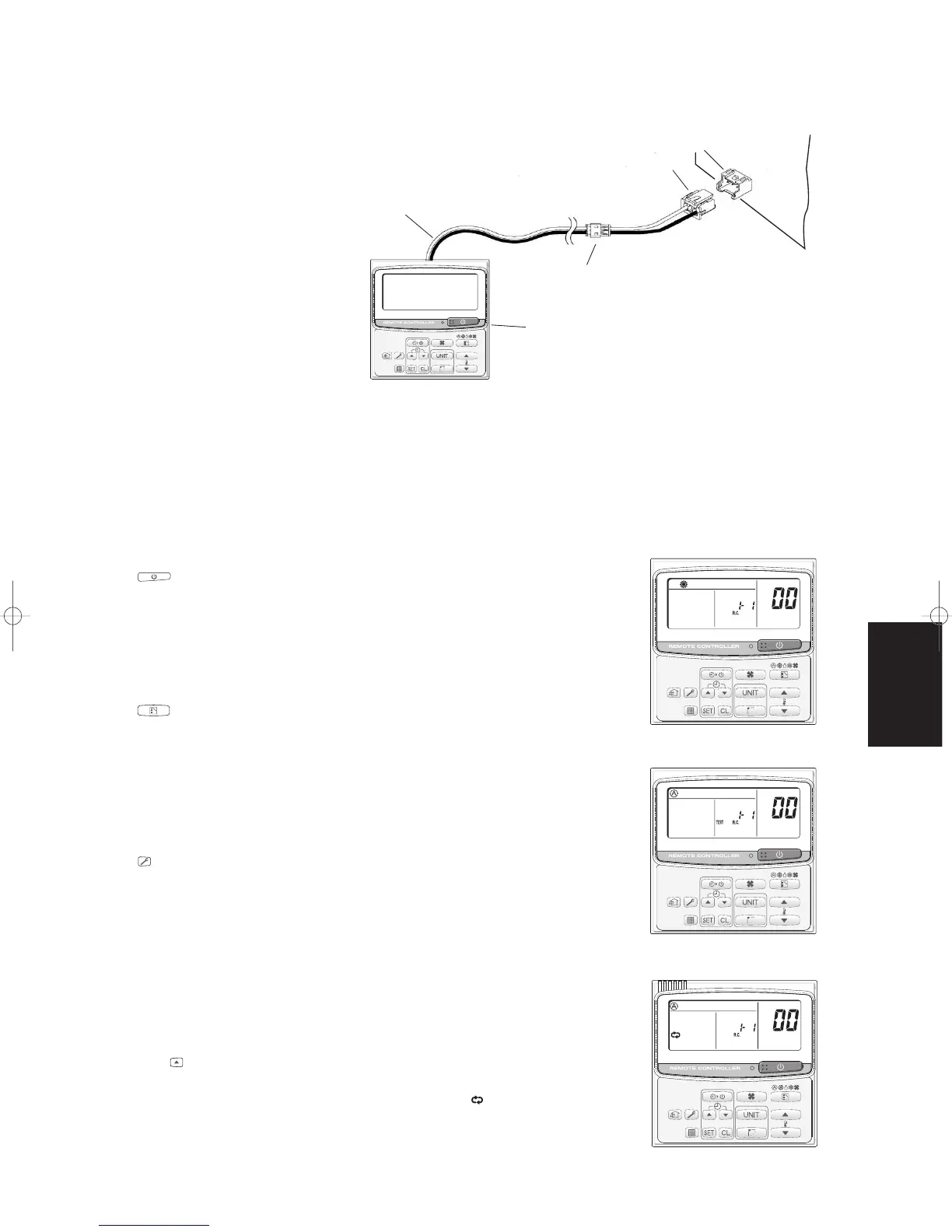

● All units start/stop (Fig. 1)

<Operation>

The button can be used to start and stop all the indoor units.

• The LED turns ON when 1 or more indoor units is operating.

• The LED blinks when an alarm has occurred at 1 or more indoor

units during operation.

● Switching between cooling/heating (Fig. 1)

<Operation>

The button switches between heating and cooling modes.

• The specifications are equivalent to the heating/cooling input that

was present on earlier outdoor unit PCBs.

• The display shows the operating mode of the indoor unit with the

lowest number.

● All units test run (Fig. 2)

<Operation>

The button switches test run ON/OFF for all indoor units.

• Press and hold for 4 seconds to turn ON.

“Test run” is displayed while the test run is in progress.

• Conditions of test runs that are started from the unit remote con-

troller are not displayed on the outdoor unit maintenance remote

controller.

● High-speed operation (Fig. 3)

• Do not use with actual units. (The devices may be damaged.)

<Operation>

The time button changes between high-speed operation and

normal operation.

• During high-speed operation, the “repeat” timer mark is dis-

played.

Fig. 1

Fig. 2

Fig. 3

Loading...

Loading...