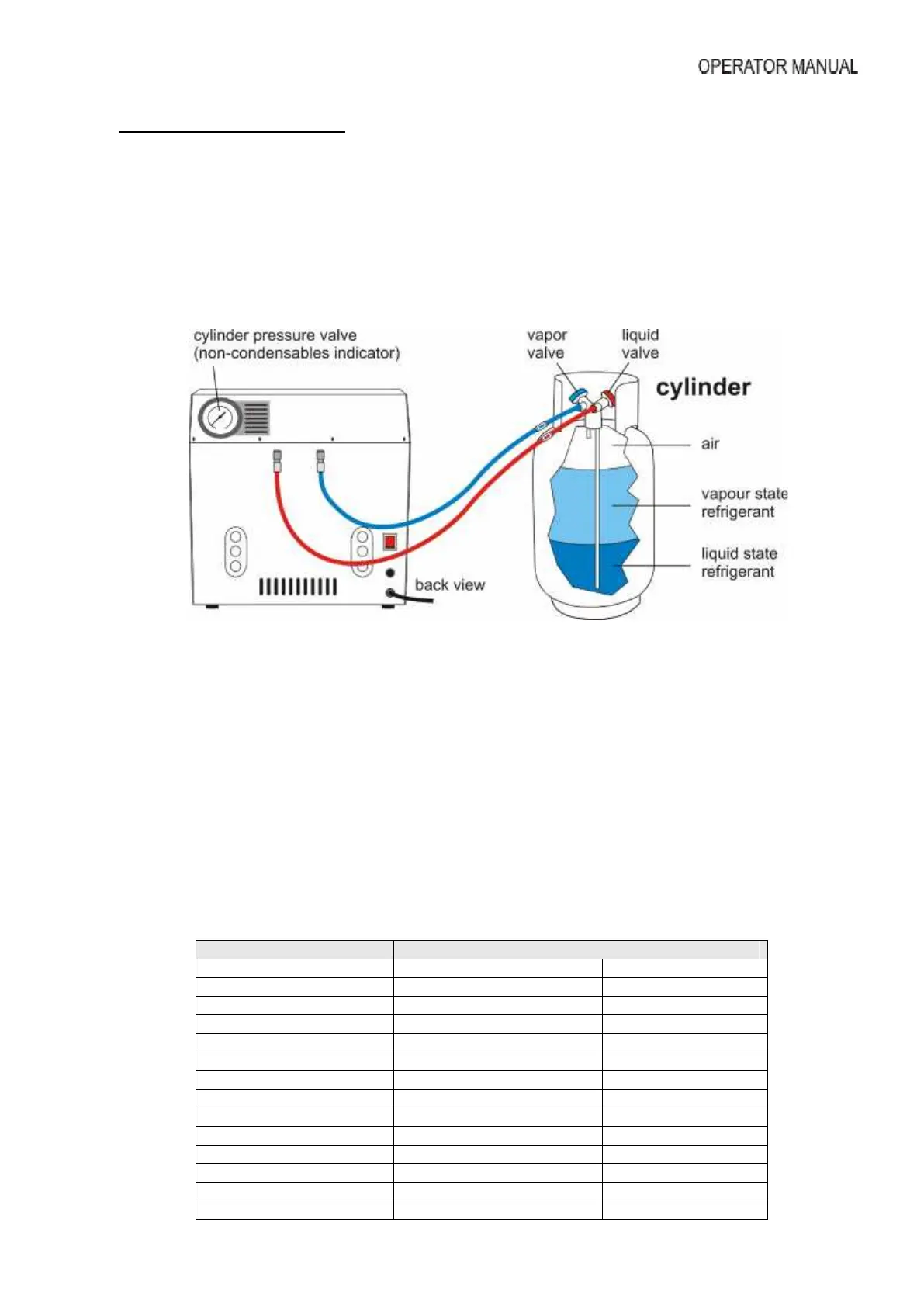

13. Cylinder Air Purge

Air is not good for A/C system because it is a non-condensable gas. It is possible to get inside the

cylinder during the proces of recovery of contaminated a/c system (system which leaks or not

properly evacuated).

To check the cylinder for air contamination, a technician should read the pressure on the

refrigerant in storage cylinder to see if it exceeds the maximum allowable pressure for a given

ambient temperature. If it does, there is air in the cylinder and needs to be purged (through

cylinder vapor valve).

First, measure the ambient temperature. Then read the cylinder pressure on rear gauge (13) and

compare it with the temperature pressure chart, affixed to the machine.

If the cylinder pressure is higher than the pressure/temperature chart, there are non-condensable

gases (air) in the cylinder.

- Disconnect the vapour hose from cylinder.

- Slightly OPEN cylinder vapour valve to purge the non-condensable gases (air) from the

cylinder to bring back the pressure to the recommended chart values.

Note: After recovery process it is normal that cylinder pressure is higher than the

pressure/temperature chart shows. Always read the cylinder pressure first thing in the

morning before operating the machine.

Example: Ambient temp. 20

o

C, the cylinder pressure should be 4.7 bar (68 PSI).

Loading...

Loading...