EN - 14

1. Stop engine, remove key and close fuel

valve. Allow unit to cool.

See Figure 12.

2. Tip unit back onto engine guard. DO NOT

tip further than engine guard allows or oil

may leak out of engine.

3. Remove six hex bolts, washers and top

locking flange nuts securing each paddle

to center plate and side plates. Discard all

parts.

IMPORTANT: Do not remove center plate.

4. Position new paddles with wear indicator

holes on the left side as you face the unit.

5. Install spacers into paddle holes and

secure paddle with new hex bolts and

nuts.

6. Tighten nuts to 5.6 – 10.2 N•m (50 – 90

lb-in). DO NOT overtighten.

7. When both paddles are installed, rotate

auger paddles by hand. Ensure that

paddles do not rub on housing and are

tightly attached.

8. Return unit to operating position.

9. Remove slack from auger cable. See

Adjust Auger Cable on page 14.

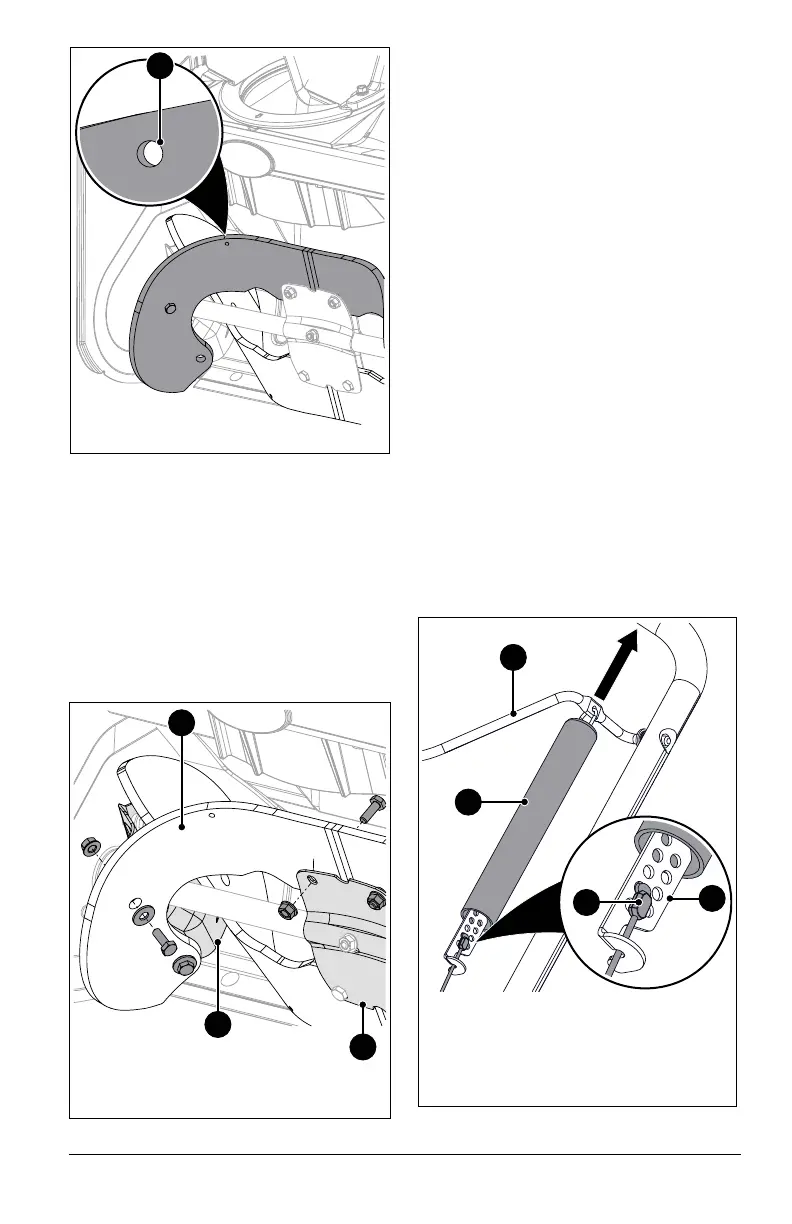

ADJUST AUGER CABLE

See Figure 13.

1. Stop engine, remove key and close fuel

valve.

2. Slide plastic sleeve up to auger control

bar.

3. Insert Z-hook into appropriate hole in

adjustment bracket. When auger control

bar is disengaged, there should minor

slack in cable and no tension.

4. Engage auger control bar to ensure

proper operation. There should be no

excessive tension on cable.

5. Lower plastic sleeve.

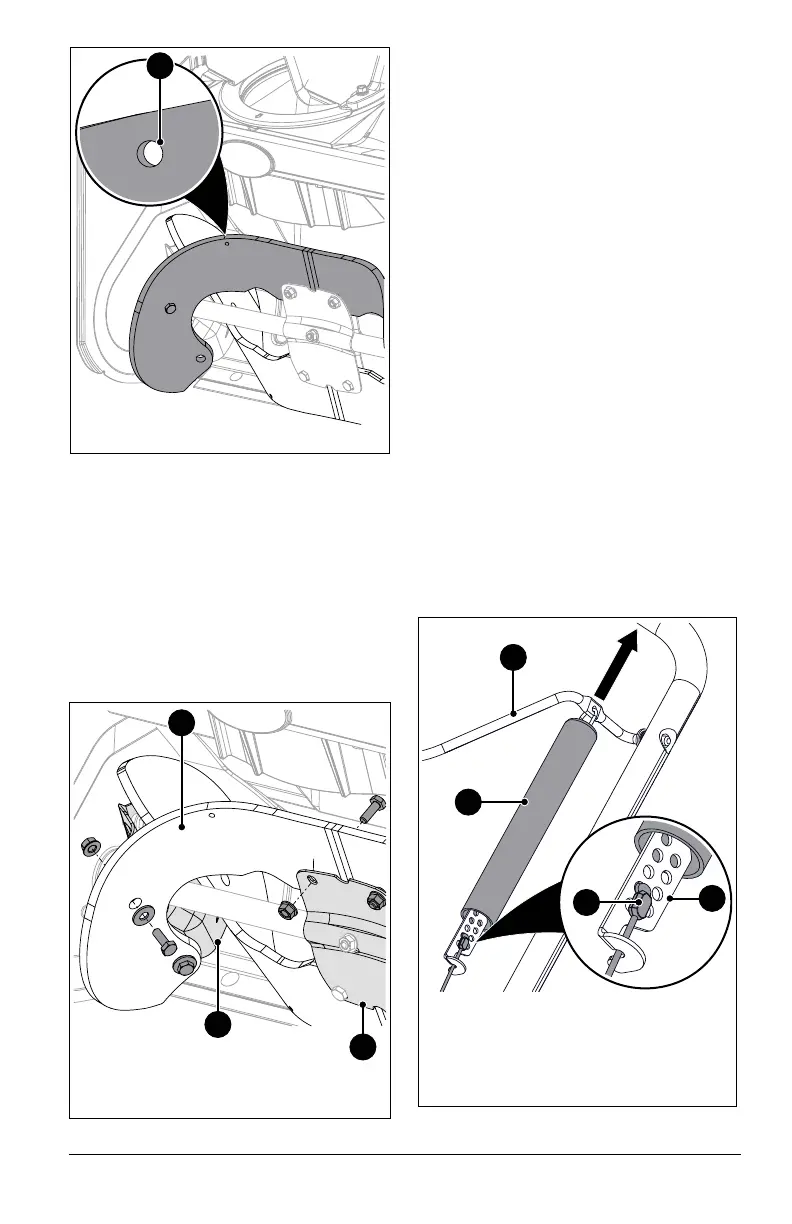

Figure 11

1. Wear Indicator Hole

1

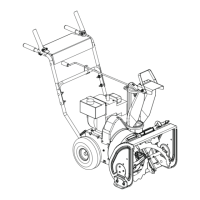

Figure 12

1. Auger Paddle

2. Side Plate

3. Center Plate

1

2

3

Figure 13

1. Auger Control Bar

2. Plastic Sleeve

3. Z-hook

4. Adjustment Bracket

1

2

3

4

Loading...

Loading...