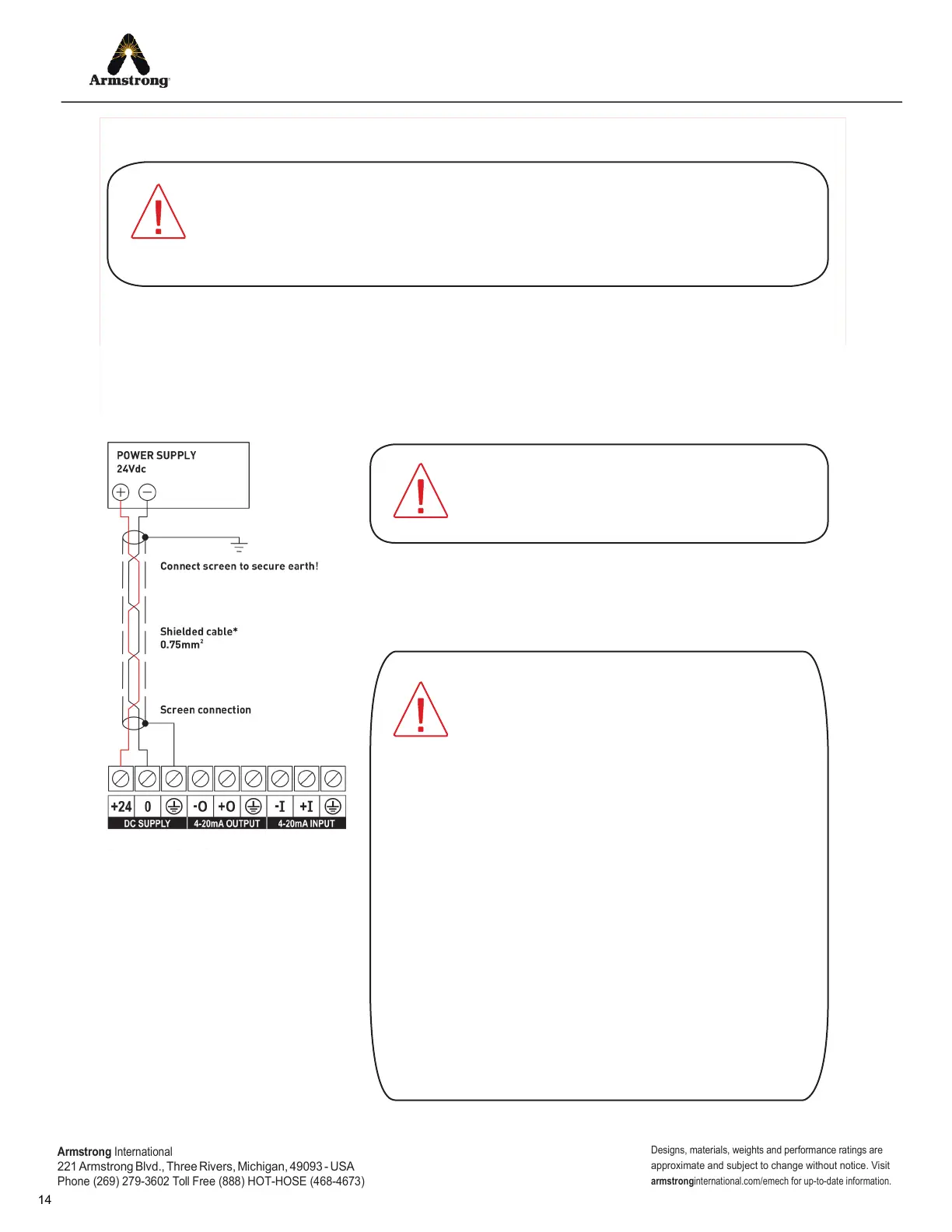

3.2 Wiring Instructions

3.2.1 Power Supply Wiring

Wire the supply connections as indicted below using the correct diameter shielded cable. When placing the wiring

in metal conduit, which is earthed, shielded cable is not required.

WIRE THE SUPPLY FIRST (before making any other connections). Insure that the actuator supply

consists of a 24Vdc supply (not AC) and that the voltage tolerances are within the permissible

voltage limits of the actuator.

SWITCH THE SUPPLY OFF BEFORE CONNECTING!

Ensure conduits and wire screens are properly

grounded to reduce possible effects of EM

(Electromagnetic Interference) on actuator operation.

REFER to Table 3.1 as a guide for wiring cable lengths and voltage drops.

WARNING !!

When the actuator is wired up to the power supply, it is

important that the voltage drop to the actuator remains

no more than 1-2Volts when the actuator is operating

under load.

To check this, put a meter on the DC supply terminals at

the unit, and measure the 24vDC supply.

Keeping the meter in place, use the manual handle to

move the valve out of position . or change a set value so

the actuator is instructed to move.

IF YOU OBSERVE GREATER THAN 2 VOLTS DROP

ON THE POWER SUPPLY AT THE ACTUATOR WHEN

OPERATING, PLEASE REVIEW AND INCREASE WIRE

DIAMETER BEING UTILIZED TO MINIMISE VOLTAGE

DROP OVER DISTANCE OF CABLE RUN.

EXCESSIVE VOLTAGE DROP AT THE ACTUATOR

UNDER LOAD CAN LEAD TO UNRELIABLE

PERFORMANCE AND POTENTIALLY PERMANENT

DAMAGE TO THE INSTALLED UNIT.

Figure 3.2: Supply Connection

Armstrong

International

221

Armstrong Blvd., Three Rivers, Michigan, 49093 - USA

Phone (269) 279-3602 Toll Free (888) HOT-HOSE (468-4673)

Designs, materials, weights and performance ratings are

approximate and subject to change without notice. Visit

armstrong

international.com/emech for up-to-date information.

Continued.....

Loading...

Loading...