Page 2 of 8 (Section 1 of 2) Form No.V6928R3 - Sec. 1

50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

CHANGING MODE OF OPERATION

WARNING: To prevent the possibility of death,

personal injury or property damage, turn off

electrical power, depressurize valve, and vent

fluid to a safe area before changing mode of

operation.

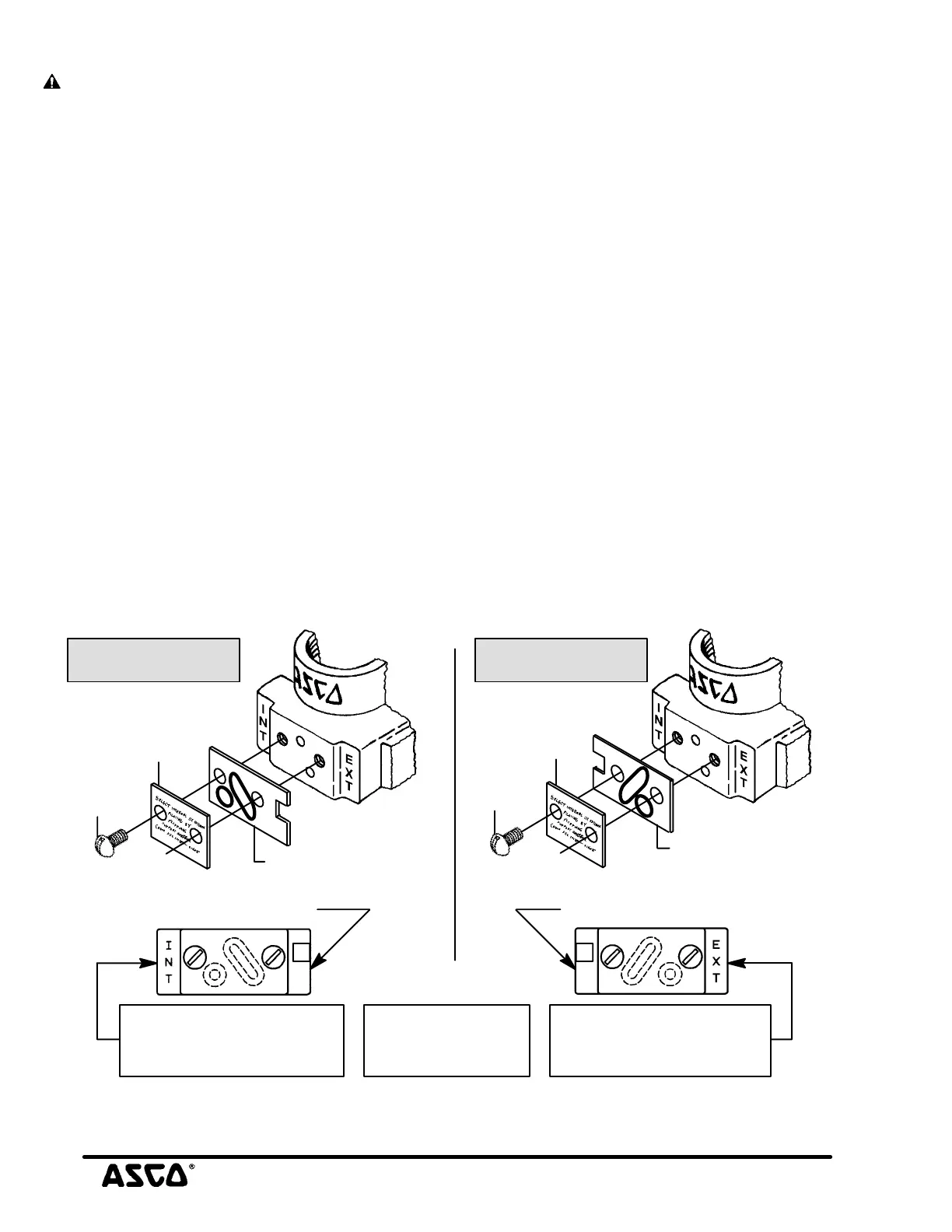

The piloting (Mode of Operation) of the valve is determined by

the positioning of the Support with Flow Gaskets on the side of

the valve body. See Figures 1 & 2 for proper positioning of

Support with Flow Gaskets for internal or external piloting

mode of operation.

Positioning of Support with Flow Gaskets for Internal

Piloting Mode

To change to the Internal Piloting Mode of operation if

previously installed in the external piloting mode or rebuild

after valve disassembly for maintenance, proceed as follows:

1. Install a 1/8I NPT pipe plug in the port marked AUX,

auxiliary pressure connection.

NOTE: To change to internal piloting, remove cover screws (2),

cover and support with large and small flow gaskets. Just turn

over the support 180_ to change piloting and reassemble. To

verify piloting selection, follow rebuild instructions steps below.

2. Refer to views in Figure 1 for proper location and position

of parts for Internal Piloting Mode of operation.

3. Position large and small flow gaskets in support. Large

gasket must be compressed to fit support configuration.

4. Line up support (with flow gaskets) on side wall of valve

body using machine screw holes as a guide. When support

is correctly positioned (as shown in Figure 1.) the letters

INT are visible and letters EXT on opposite side are

covered by the support. Confirm proper alignment with

views in Figure 1. Then replace cover and cover screws.

Torque cover screws evenly to 13 ± 1 in-lbs [1,5 ± 0,1

Nm].

5. Refer to OPERATION - INTERNAL PILOTING MODE

section.

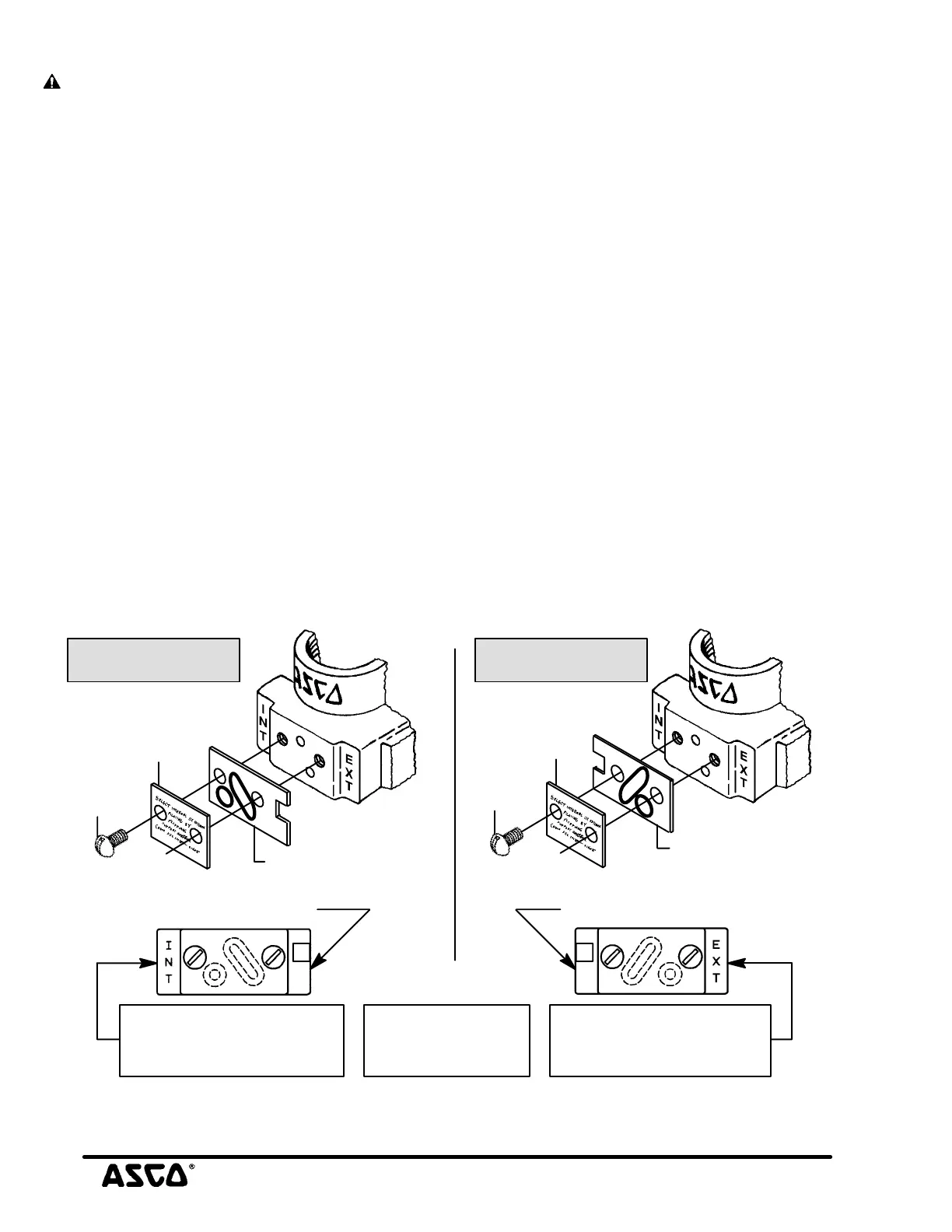

Positioning of Support with Flow Gaskets for External

Piloting Mode

To change to the External Piloting Mode of operation before

valve installation or rebuild after valve disassembly for

maintenance, proceed as follows:

1. Remove a 1/8I NPT pipe plug from auxiliary pressure

connection port marked AUX, using a 5/16I hex key

wrench and connect auxiliary pilot pressure piping.

NOTE: To change to external piloting, remove cover screws

(2), cover and support with large and small flow gaskets (2).

Just turn over the support 180_ to change piloting and

reassemble. To verify piloting selection, follow rebuild

instructions steps below.

2. Refer to views in Figure 2 for proper location and position

of parts for External Piloting Mode of operation.

3. Position large and small flow gaskets in support. Large

gasket must be compressed to fit support configuration.

4. Line up support (with flow gaskets) on side wall of valve

body using machine screw holes as a guide. When support

is correctly positioned (as shown in Figure 2.) the letters

EXT are visible and letters IN T on opposite side are

covered by the support. Confirm proper alignment with

views in Figure 2. Then replace cover and cover screws.

Torque screws evenly to 13 ± 1 in-lbs [1,5 ± 0,1 Nm].

5. Refer to OPERATION - EXTERNAL PILOTING MODE

section.

support with large and

cover with

instructions

screw(2)

support with large and

cover with

instructions

INT" marking shown. This

indicates correct assembly

for internal piloting

EXT" marking shown. This

for external piloting

EXT" mark is covered INT" mark is covered

indicates correct assembly

screw(2)

small flow gaskets

small flow gaskets

Large and small

flow gaskets shown

in phantom

Internal Piloting External Piloting

cover

cover

Figure 1. Positioning of support with Figure 2. Positioning of support with

flow gaskets for internal piloting mode. flow gaskets for external piloting mode.

Loading...

Loading...