Page 6 of 8 (Section 2 of 2) Form No.V6928R3 - Sec. 2

50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

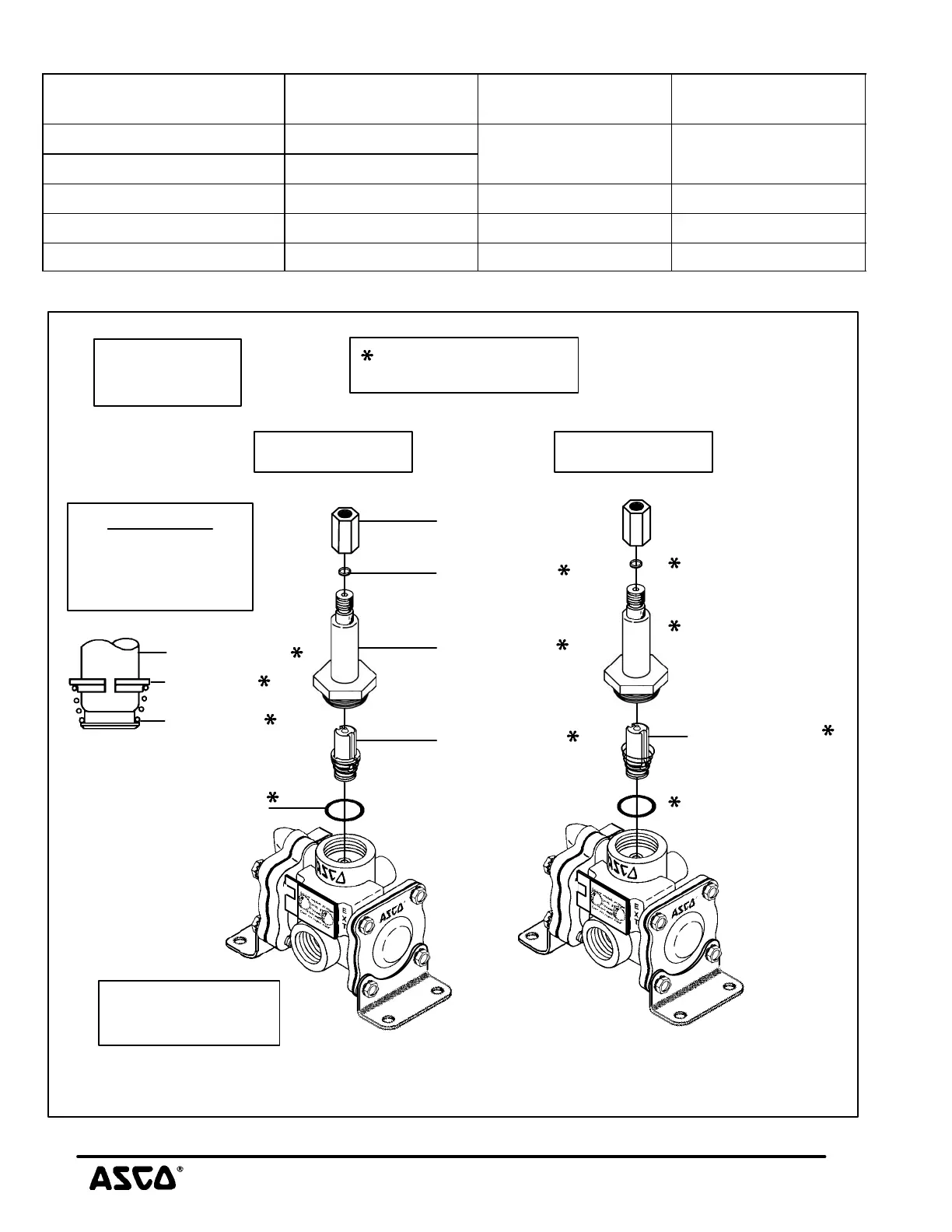

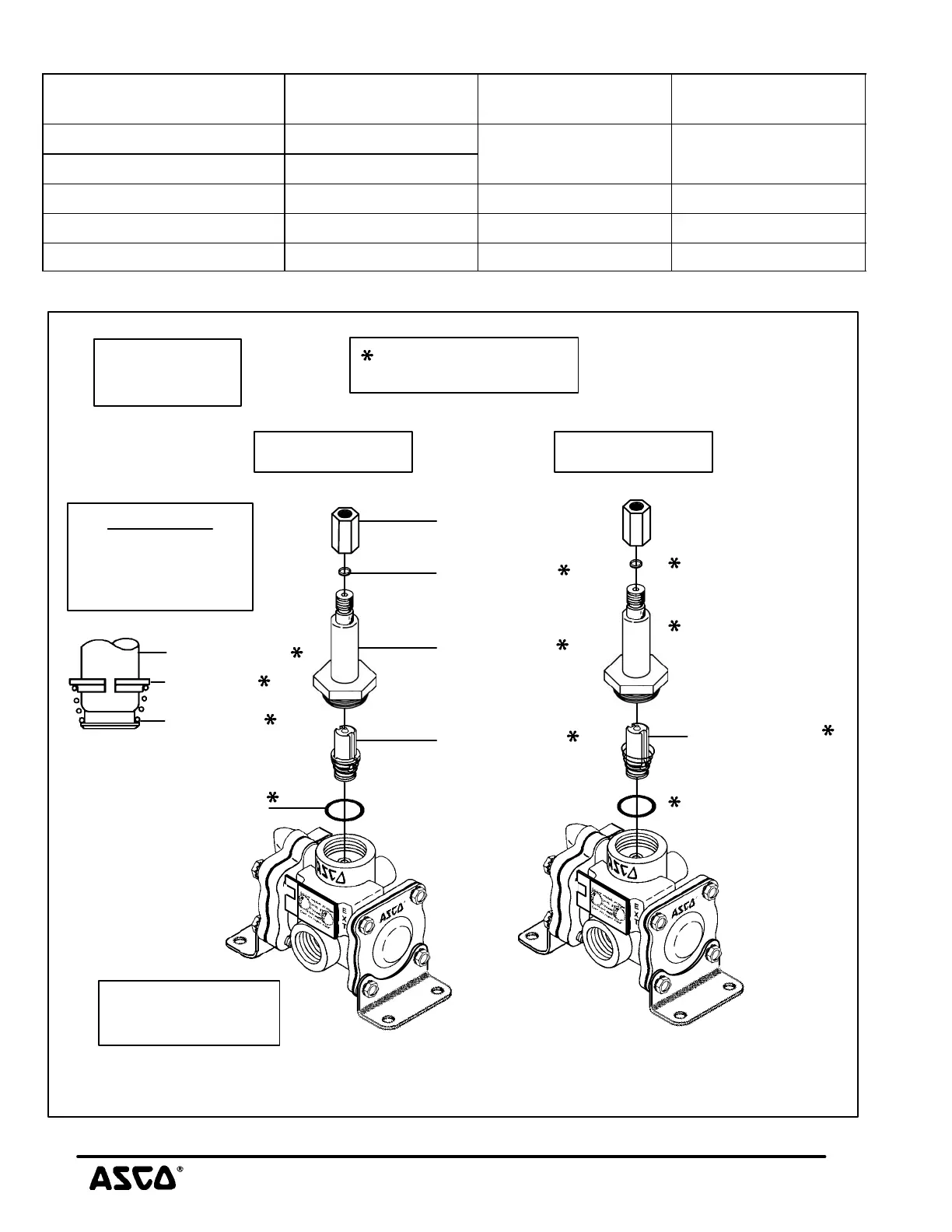

Torque Chart

Part Name

(see note)

Wrench Size

or Tool

Torque Value

Inch-Pounds

Torque Value

Newton-Meters

Cartridge assembly 1 1/8I

Solenoid base sub-assembly 1I

175 ± 25 19,8 ± 2,8

Bonnet screws 7/16I 95 ± 10 10,7 ± 1,1

Cover screws screw driver 13 ± 1 1,5 ± 0,1

Pipe adapter 11/16I 90 maximum 10,2 maximum

Note: Thread all parts by hand as far as possible. Then torque evenly in a crisscross manner where applicable.

Figure 6. Partial view of solenoid parts for standard valve constructions. See Figures 7 or 8

for disassembly and reassembly of main valve body.

core assembly

core spring

core guide

IMPORTANT

Partial cutaway view

showing positioning

of core guide on

core assembly.

Indicates parts supplied

in ASCO Rebuild Kit

DC ConstructionAC Construction

core assembly

(with core spring)

pipe adapter

plugnut gasket

solenoid base

sub-assembly

core assembly

(with core guide

and core spring)

solenoid base gasket

(1/4I NPT)

5/16I orifice valve

construction shown

See Torque and

Lubrication Chart

Important

Loading...

Loading...