Page 3 of 8 (Section 1 of 2)Form No.V6928R3 - Sec. 1

50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

INSTALLATION

Check nameplate for correct catalog number, pressure,

voltage, frequency, and service. Never apply incompatible

fluids or exceed pressure rating of the valve. Installation and

valve maintenance to be performed by qualified personnel.

Future Service Considerations

Provision should be made for performing seat leakage, external

leakage, and operational tests on the valve with a

nonhazardous, noncombustible fluid after disassembly and

reassembly.

Temperature Limitations

Ambient and Fluid Temperature Ranges:

S Standard Valves:

AC Construction -4_F (- 20_C) to 125_F (54_C):

DC Construction - 4_F (- 20_C) to 104_F (40_C):

S Low Power &

Intrinsically Safe: -20_F (- 29_C) to 140_F (60_C):

: For optimum performance, not recommended below 32_F

(0_C) on Suffix V" elastomer constructions.

Positioning

Valve may be mounted in any position.

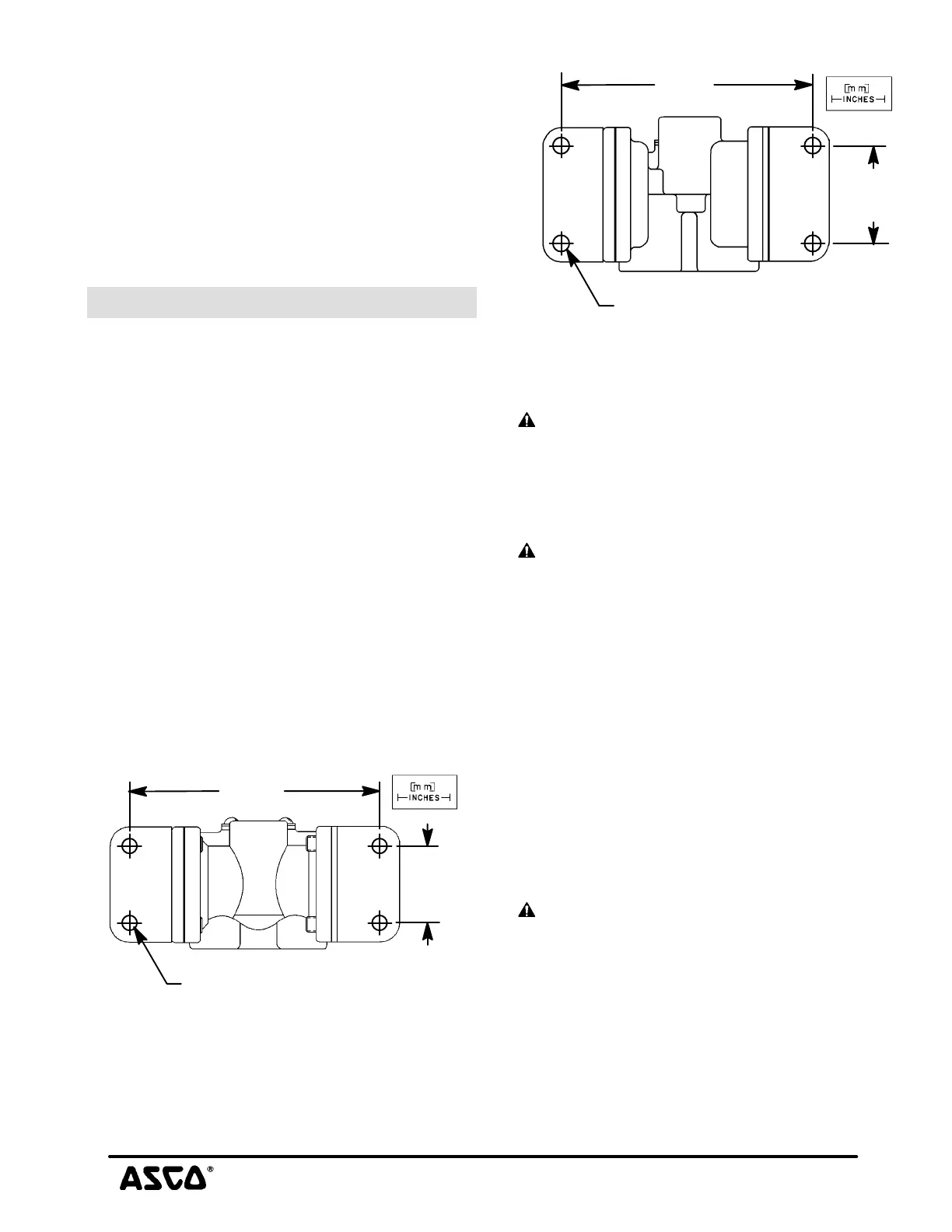

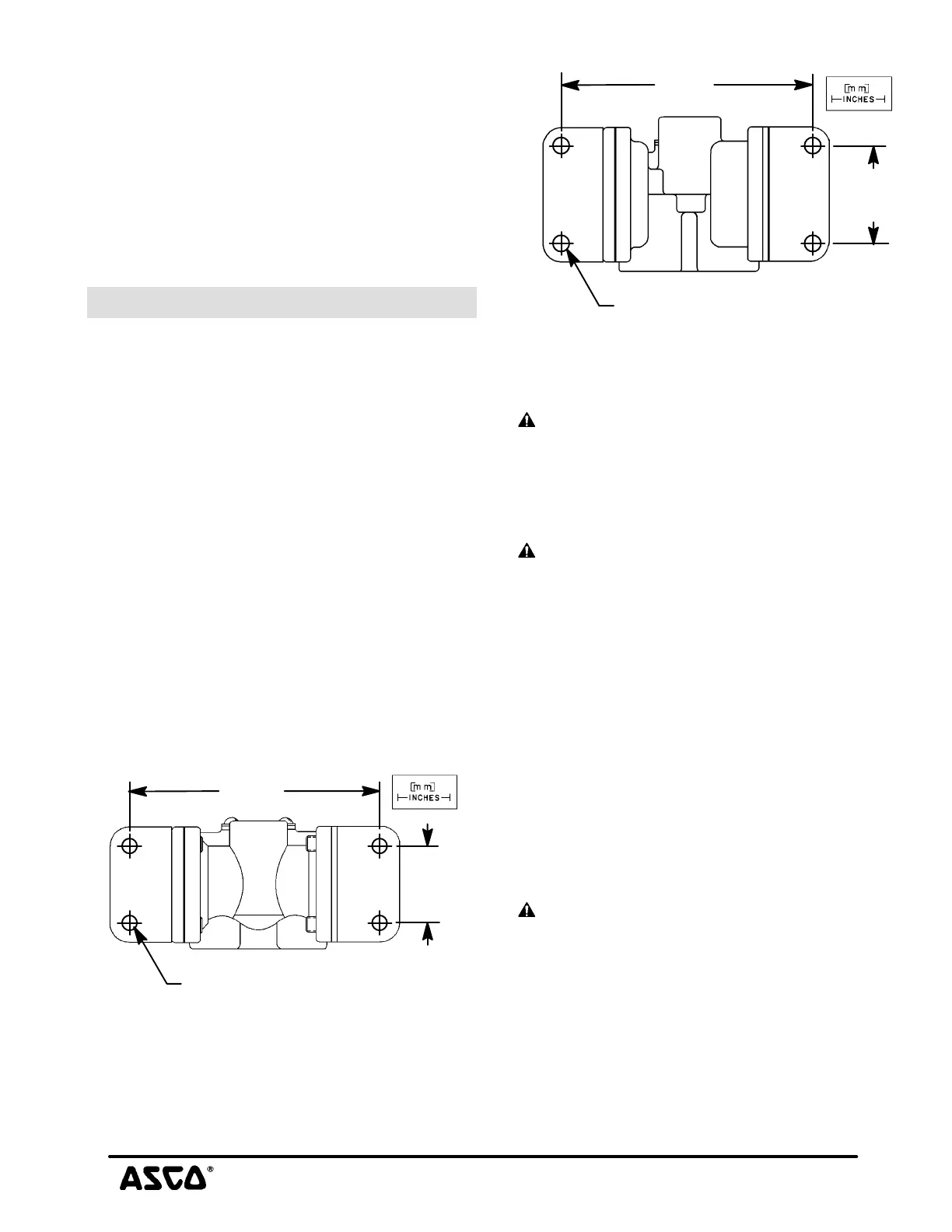

Mounting

Mounting brackets (2) are optional. For valves with a 5/16I

orifice, 1/4I or 3/8I NPT refer to Figure 3; for 5/8I orifice, 3/8I

or 1/2I NPT Figure 4. Check nameplate to determine orifice

sizeāĂandāĂpipeāĂsize.

Figure 3. Mounting dimensions - 5/16I Orifice

4.05

[103]

[32]

1.25

.28 diameter [Ø7,1] 4 places

Figure 4. Mounting dimensions - 5/8I Orifice

4.27

[108]

[42]

1.66

.28 diameter [Ø7,1] 4 places

Piping

There are two exhaust flows in the exhaust mode. There is pilot

exhaust from the top of the solenoid when the valve shifts.

CAUTION: Debris entering 1/8I or 1/4I NPT

connection at top of solenoid may cause valve to

malfunction. Use a muffler to vent to atmosphere or

connect to main exhaust system if the air or inert gas

cannot be exhausted directly to the atmosphere.

Connect piping or tubing to valve according to markings on

valve body. Refer to flow diagrams in OPERATION section.

CAUTION: To avoid damage or accidental

disengagement of cartridge assembly from valve body,

hold cartridge assembly securely by wrenching flats

when installing or removing muffler or piping at top of

solenoid.

Apply pipe compound sparingly to male pipe threads only. If

applied to valve threads, the compound may enter the valve and

cause operational difficulty. Avoid pipe strain by properly

supporting and aligning piping. When tightening the pipe, do

not use valve or solenoid as a lever. Locate wrenches applied

to valve body or piping as close as possible to connection point.

Internal Piloting Mode Only: To insure proper operation of the

valve, the pressure and exhaust piping must be full area without

restriction. A minimum differential pressure (15 psi), as

stamped on the nameplate, must be maintained between

pressure and exhaust at the moment of shifting. Air reservoirs

must have adequate capacity to maintain this minimum

pressure during shifting. To check pressure during shifting,

install a pressure gauge in the pressure piping as close to the

valve as possible.

CAUTION: These solenoid valves are intended for

use on clean dry air or inert gas, filtered to 50

micrometres or better. The dew point of the media should

be at least 10_ C (18_ F) below the minimum temperature

to which any portion of the clean air/inert gas system

could be exposed to prevent freezing. If lubricated air is

used, the lubricants must be compatible with Buna N

elastomers. Diester oils may cause operational

problems. Instrument air in compliance with ANSI/ISA

Standard S7.3-1975 (R1981) exceeds the above

requirements and is, therefore, an acceptable media for

these valves.

Loading...

Loading...