10

T-BAR ASSEMBLY

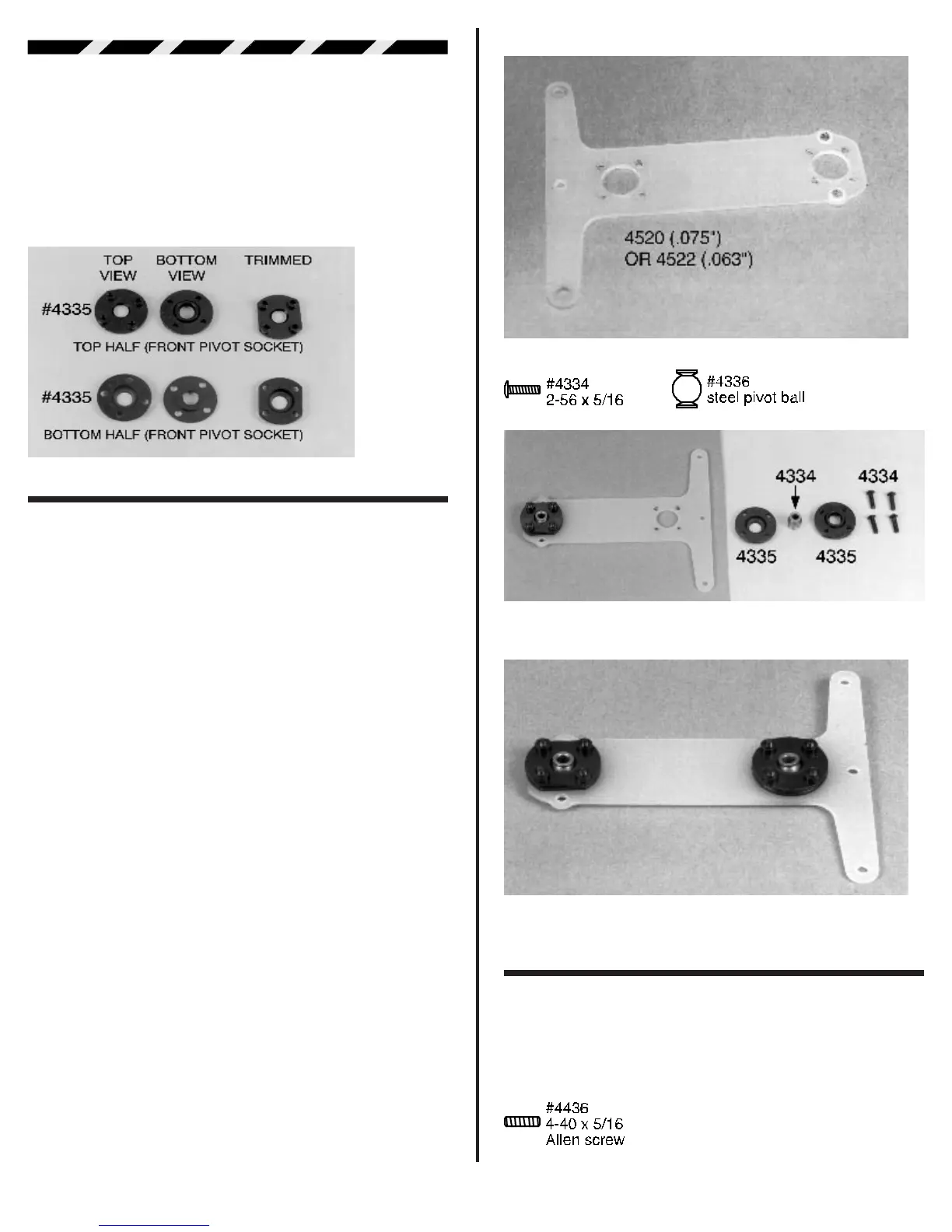

❑ Fig. 21 Now we can open bag #2. Start by taking out

the two #4335 plastic pivot sockets. There are two halves to

each socket. Take one upper and lower portion of the pivot

socket. This will become the front pivot socket. Look at the

photo, you will see how much you must trim from each side of

the two halves. We only have to do this for the front pivot socket.

Fig. 21

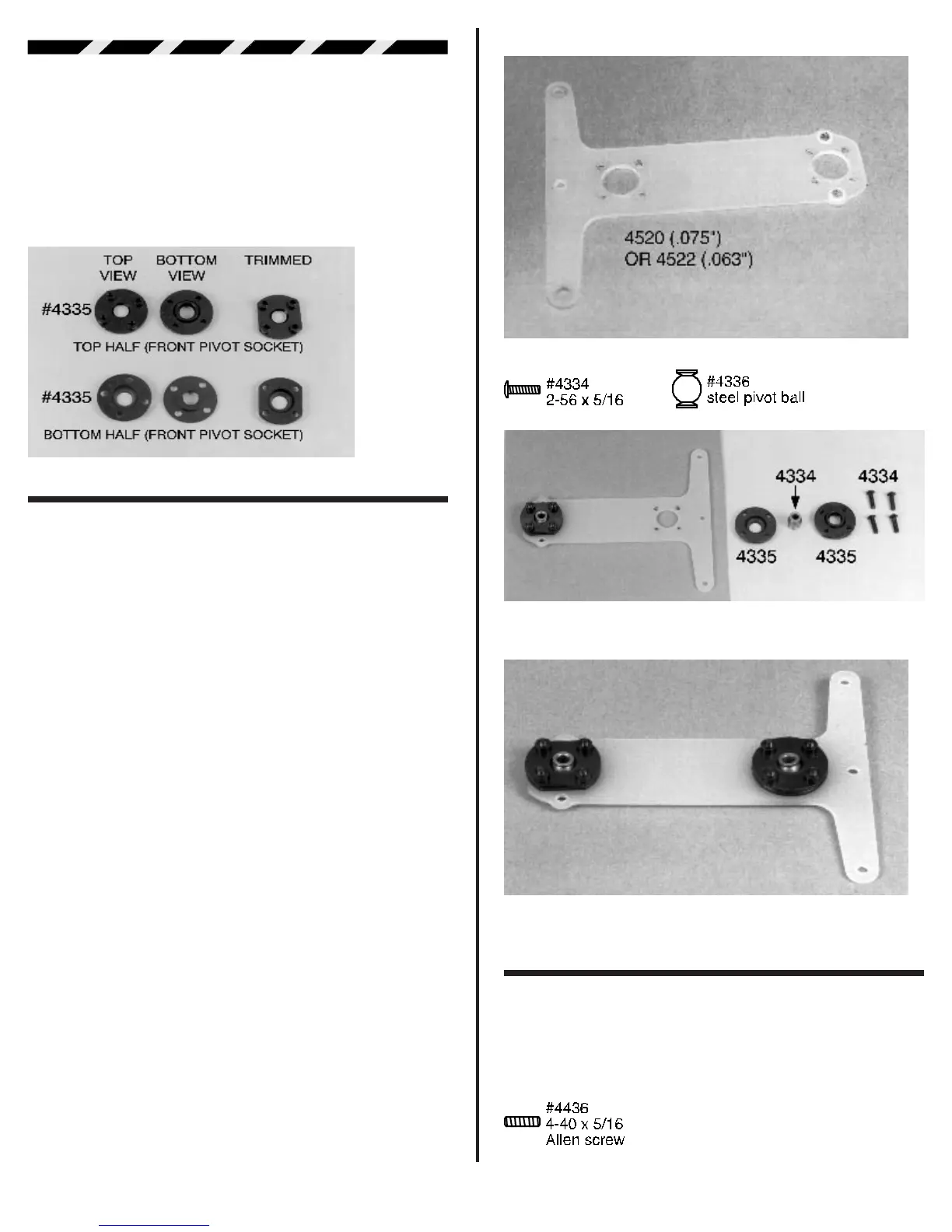

❑ Figs. 22, 23 & 24 In bag #2 you will find one

#4520 .075” fiberglass T-bar and one #4522 .063” fiberglass T-

bar. The .075" and .063" refer to the thickness of the T-bar. If

you are going to be racing on asphalt you will want to start with

the #4522 .063” T-bar. If you are going to race on carpet we

recommend starting with the #4520 .075” T-bar. There is no top

or bottom on the T-bar until the pivot sockets have been

installed.

Now remove two #4336 steel pivot balls and eight

#4334 2-56 x 3/16” BHSScrews from the same bag. We will

start with the front pivot socket assembly which we modified in

fig. 21. Look at the lower half of the pivot socket. There is a

raised portion that will match the hole on the front of the T-bar.

Place the socket into the hole and line up the trimmed sides as

shown. This will leave the tweak screw holes exposed. Now

take one of the #4336 steel pivot balls and snap it into the center

of the lower pivot socket. Place the upper portion over the steel

pivot ball. Be sure to line up the trimmed sides on both halves.

Holding the socket parts in place with your fingers, turn the T-

bar and socket parts upside down. Now use your .050” Allen

wrench from your tool bag and four of the #4334 2-56 screws

to secure the socket to the T-bar. This will place the heads of

the screws on the bottom of the T-bar and the socket and ball

parts on top.

Note: It is very important to make sure the Allen

wrench is fully seated into the socket portion of the screw or

they will strip out.

Now repeat the above assembly for the second pivot.

For this pivot the ball must pivot freely in the socket while not

being loose. If the ball is not pivoting freely, you can equally

unscrews all four #4434 screws 1/8 to 1/4 turn. However the

best way to make the ball pivot freely is to remove the pivot ball

and polish it. You can do this by placing the ball on a long 4-40

screw and securing it with a 4-40 nut. You would then mount the

screw in a drill press, hand drill, or a Dremel tool, then polish the

ball with crocus cloth or 600 grit wet or dry and paper. Clean the

ball off and reinstall it and check the movement. Keep doing this

until the ball pivots freely, but is not loose.

Fig. 22

Fig. 23

Fig. 24

❑ Fig. 25 In the same bag you will find two #4436 4-40

x 5/16” socket set screws. Install the two set screws into the two

holes next to the front pivot socket as shown. The holes for the

set screws are not threaded so take your time when threading

them in. You will again be using your .050” Allen wrench with

these screws.

Loading...

Loading...