Problem Solutions

Applicator and supply hose

overheat

1. Determine exact voltage of the melt unit. Insufficient

voltage can be the cause of these problems. Voltage

drops are common. Use a voltmeter to determine

whether sufficient voltage is supplied to the melt

unit. Also, the voltage of each melt unit component

must be compatible to the melt unit or serious

damage to the system will occur. (Refer to

section 4.4, Electrical Circuits & Wiring).

2. Adjust the supply hose temperature controller

according to section 5.3 in this manual. Inadequate

supply hose heat can affect the performance of your

hot melt system. If problem persists, see Hose

Controller Replacement, section 8.2, and section 9

for Hose temperature controller kits.

3. Determine if applicator is heating by using a surface

temperature probe or a temperature-sensing device.

Do not touch applicator by hand to determine

temperature. Refer to the appropriate applicator

service manual.

Pump inoperative 1. Main Breaker: Turn the system power switch to the

On position. If switch light fails to illuminate, the

switch may need replacement. System power switch

and pump motor switch must both be in the On

position for pump to operate.

2. Determine exact voltage of the melt unit. Insufficient

voltage can be the cause of these problems. Voltage

drops are common. Use a voltmeter to determine

whether sufficient voltage is supplied to the melt

unit. Also, the voltage of each melt unit component

must be compatible to the melt unit or serious

damage to the system will occur. (Refer to

section 4.4, Electrical Circuits & Wiring). Determine

exact voltage and frequency of the pump motor

marked on the motor data label located on the motor.

3. Switch the pump motor On/OFF switch to the On

position. Allow sufficient time for the melt tank to

reach operating temperature. This will cause the

pump warm-up switch to close, thus completing the

pump motor circuit. If warm-up switch is faulty or

rated at a higher temperature, it must be replaced.

Refer to section 9.

4. Determine which pump is mounted in your melt

unit. (Refer to the melt unit I.D. plate). The pumping

performance, listed in section 3 of this manual,

depends upon certain pump and pump motor

combinations. (Refer to section 9 for pump kit

information.) Look into the melt tank for any foreign

material plugging the inlet pump port. Pump gears

can freeze up; in which case the pump may need

replacement or repair.

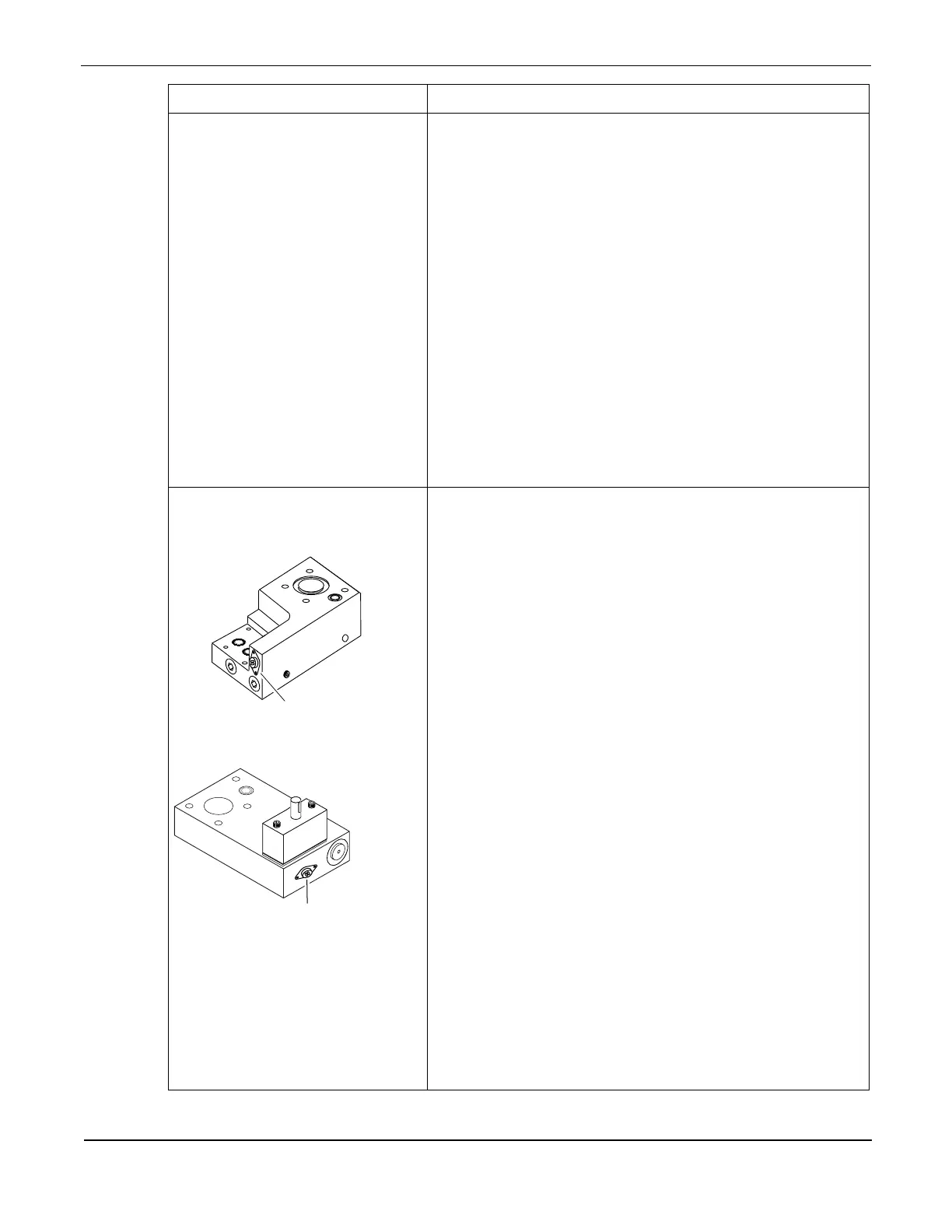

2000280

PUMP WARM-UP THERMOSTAT

(V3 and V4)

PUMP WARM-UP THERMOSTAT

(V2)

32 KB30, KB50 and KB100 Series Hot Melt Units 19600-159 Rev. A 04/09/09 © Copyright Astro Packaging 2009

Loading...

Loading...