Manual, Control Module, PROFINET, DL10

Document #9620-20-C-DL10-04

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com

C-14

2.2.1 Arc Prevention Circuit Behavior during Coupling

The Master module incorporates ATI’s Arc Prevention Circuit, which extends the life of all

electrical power contacts by eliminating arcing caused by inductive loads and high inrush current

during coupling/uncoupling. The Arc Prevention Circuit makes it possible for the customer to

couple/uncouple without switching power off and prevents damage to the contacts.

In the Master module, the Arc Prevention Circuit controls the ON/OFF status of the following (2)

power supplies:

2. Input and Logic power US1+

3. Output power US2+

The behavior of the Arc Prevention circuit is more fully described in the following sections.

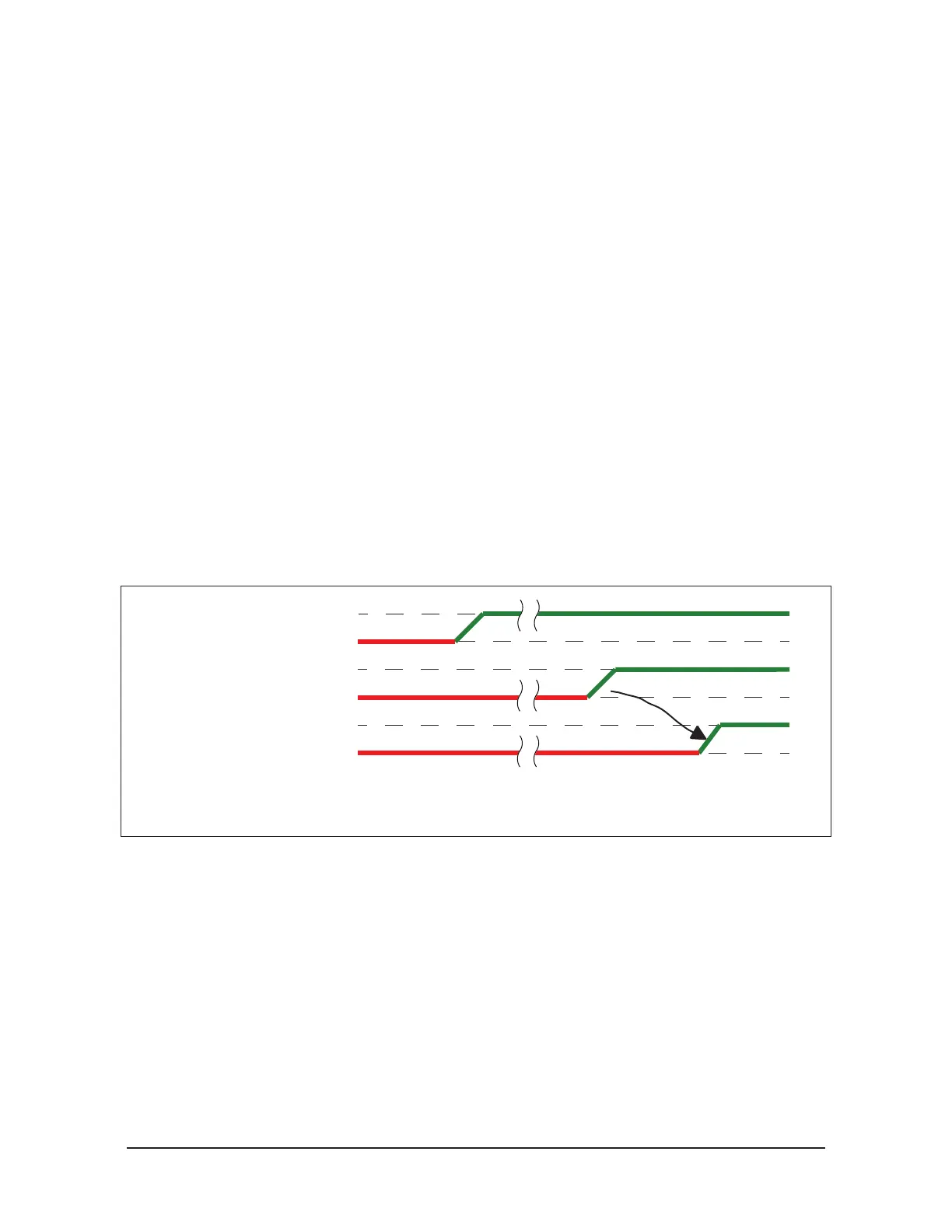

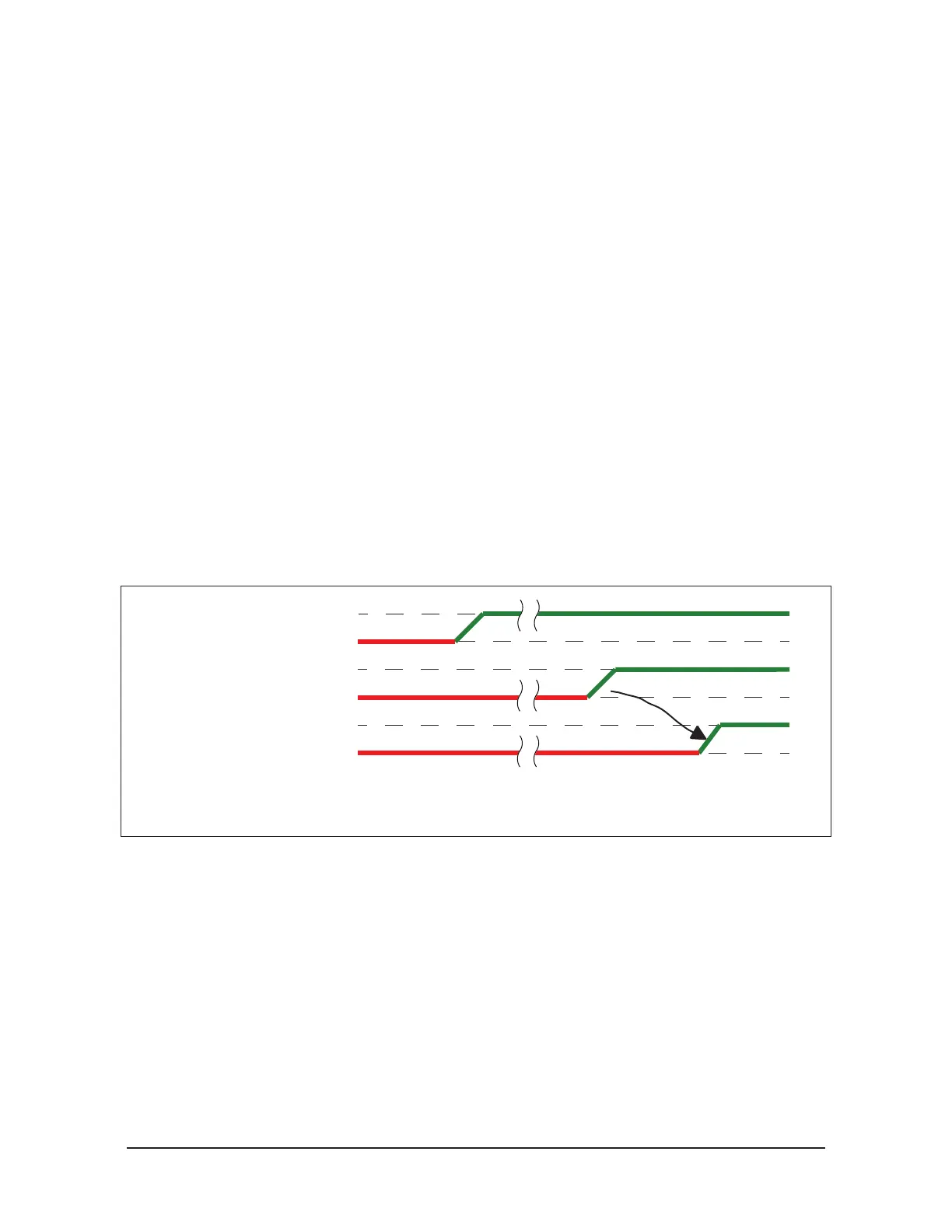

2.2.2 Arc Prevention Circuit Behavior during Coupling

The behavior of the Arc Prevention circuit during coupling can be more clearly understood by

referring to Figure 2.3.

When the robot and Master approach the Tool for pick up, electrical contact between the Master

and Tool pin contacts occurs. Soon after the Latch command is turned ON, the Arc Prevention

Circuit will turn on US1 and US2 power. The time delay between when the LATCH output is

turned ON to when power is actually available to the EOAT (time T

1 in the diagram) is less than

100 ms.

Important: The Arc Prevention Circuit will only allow power to pass to the Tool after the LATCH

command has been issued and the Master and Tool module’s electrical contacts are fully engaged.

Figure 2.3—Power On Timing

Profinet US1 and

US2 Power

Electrical Contact Between

Master and Tool

LATCH Output

ON

OFF

ON

OFF

ON

OFF

T1

T1 = Power Switch ON-delay (Less than 100 ms)

Loading...

Loading...