Manual, Robotic Tool Changer Third Generation Teaching Aids

Document #9610-20-3370-02

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

7

2. Product Overview

Teaching Aids facilitate the programming of a robot to work with ATI Tool Changers. Without using fasteners

or special tools, Teaching Aids can reduce the time required to teach the robot to pick up and drop off customer

tooling and ensure optimal X, Y, and Z alignment. Teaching Aids help extend the life of the Tool Changer alignment

pins and bushings by reducing unnecessary wear. ATI Teaching Aids have high-contrast alignment marks to aid

the user in the set-up process. When positioned, the Master Side Teaching Aid and Tool Side Teaching Aid must

have a 1 mm clearance between them. This distance ensures the No-Touch Locking zone for the Tool Changer is

set correctly. Refer to the drawings in Section 8—Drawings for more information. The following is a hyperlink to a

video that demonstrates how to use ATI’s Teaching Aids for robotic Tool Changers: http://www.ati-ia.com/library/

video_listing.aspx.

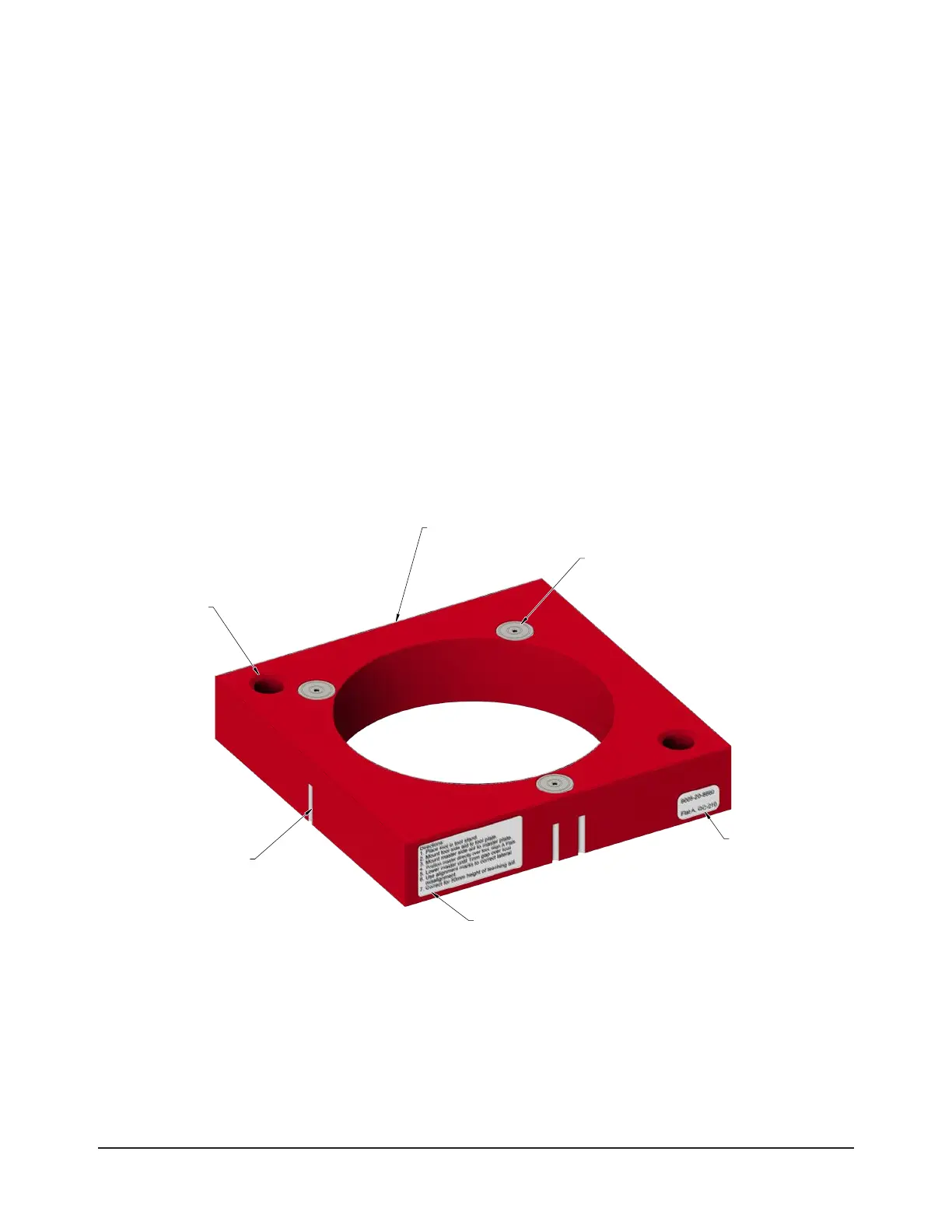

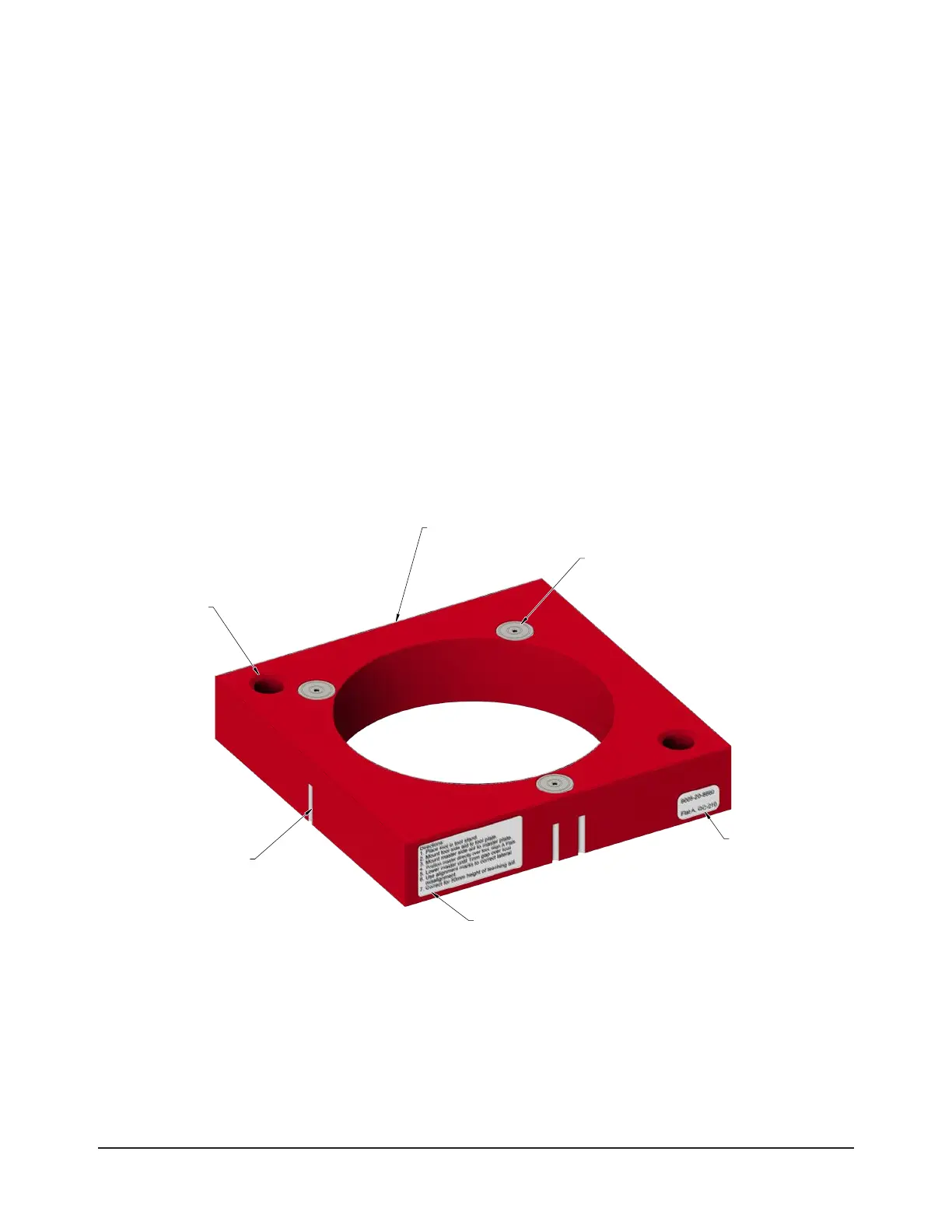

2.1 Master Side Teaching Aid

The Master Side Teaching Aid is a red, aluminum body. The interior bore ts over the Tool Changer locking

mechanism. Alignment holes are custom tted for ATI Tool Changer alignment pins. Unlike the rst

generation of Teaching Aids, the Tool Changer Master plate locking mechanism can be locked or unlocked,

when installing the Teaching Aid to the Master plate. Magnets secure the Teaching Aid to the ange of the

Master plate male coupling.

Figure 2.1—Master Side Teaching Aid (QC-210 Shown)

Label with directions.

Label with Part Number

and Flat A designation

Notch(s) for

Alignment

(3) Magnets

(2) Hole for

Alignment Pin

in the Master plate

Master Side Teaching Aid

(QC-210 Shown)

Loading...

Loading...