2920 1251 02

32

Instruction book

4.7 Service kits

Service kits

Service kits comprise all parts needed for servicing components

and offer the benefits of genuine Atlas Copco parts while

keeping the maintenance budget low. All service kits are

mentioned in the relevant Parts Lists.

Service kit for oil filters Ordering number

For GA/GA W 90 up to -160 2906 0170 00

For GA/GA W 200 up to -315 1) 2906 0199 00

Service kit for oil filters and air filters Ordering number

For GA/GA W 90 up to -160 2906 0092 00

For GA/GA W 200 up to -315 1) 2906 0200 00

Service kit for oil filters and Ordering number

heavy-duty air filters

For GA/GA W 90 up to -160 2906 0285 00

For GA/GA W 200 up to -315 1) 2906 0288 00

Atlas Copco Roto-injectfluid

Atlas Copco Roto-injectfluid (see section 4.3.1) can be ordered

in following quantities:

Quantity Ordering number

20 litre can 2901 0522 00

209 litre drum 2901 0045 01

5 ADJUSTMENTS AND SERVICING

PROCEDURES

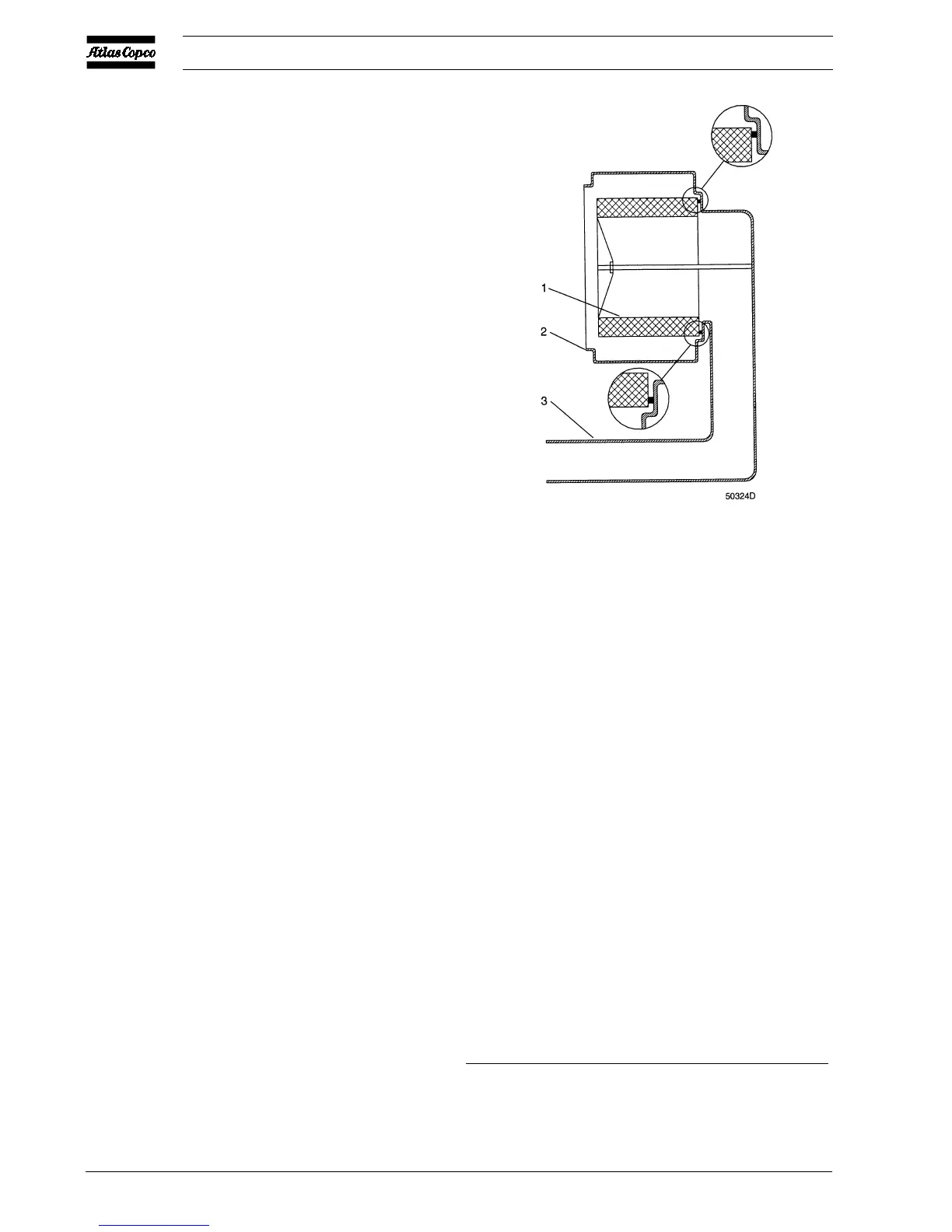

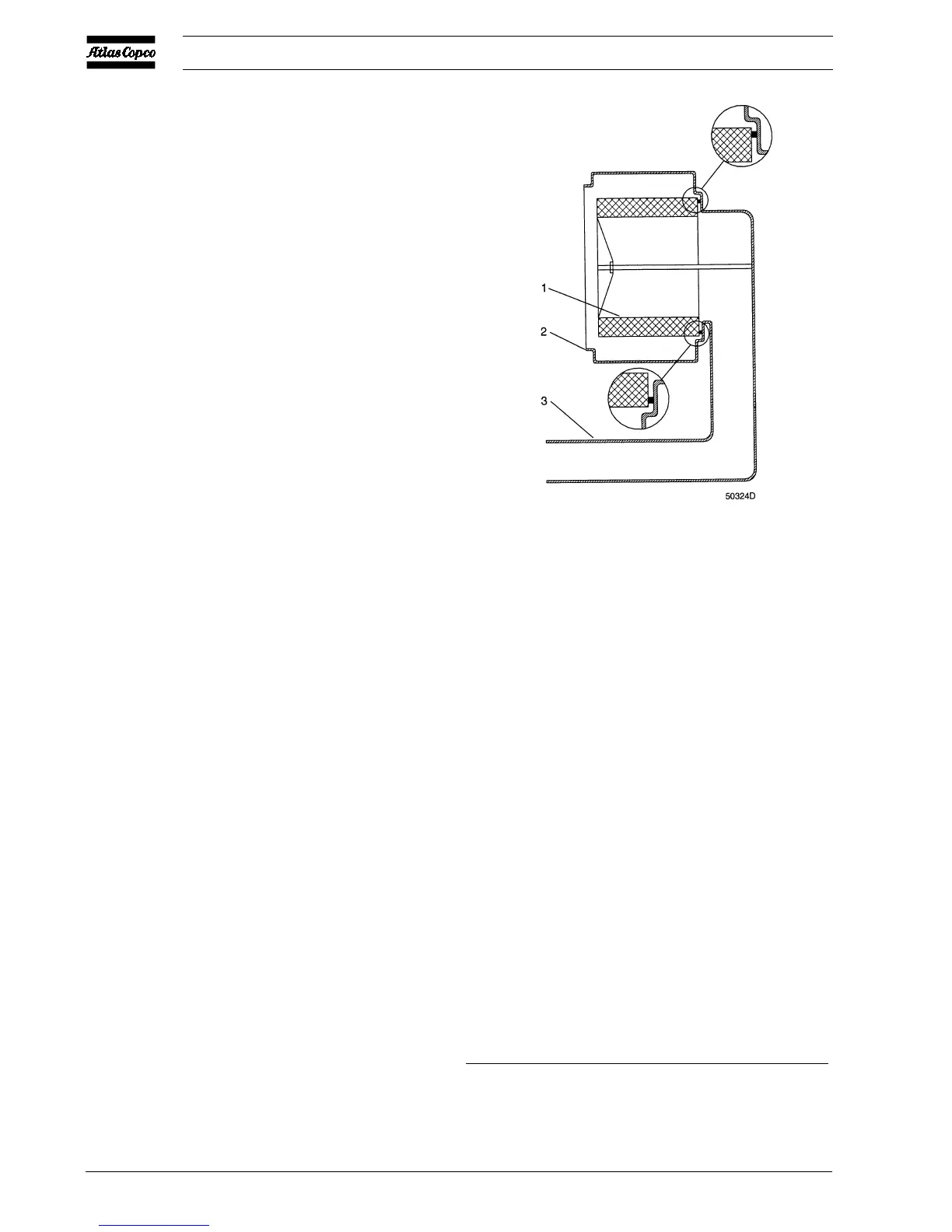

5.1 Air filters

1. Stop the compressor and switch off the voltage. Remove

the filters. 2)

2. Fit the new filters. Take care to fit the filters straight as

shown in Fig. 15.

3. Reset the air filter service warning using key <<Reset>>

in submenu <<Service>> 3).

5.2 Coolers

Keep the coolers clean to maintain the cooling efficiency.

On GA, unscrew bolts (1-Fig. 14a) and rotate the fans away

from the cooler block. Blow air from the compressor element

compartment through the coolers towards the drive motor

compartment. Remove any dirt. Reposition and fix the fans.

Make sure that the fans rotate freely.

Note

If it should be necessary to wash the coolers with a cleansing

agent, consult Atlas Copco.

On GA W, consult Atlas Copco for cleaning.

5.3 Safety valve (SV-Fig. 1a)

Operating

Operate the safety valve by unscrewing the cap one or two turns

and retightening it.

Testing

The valve can be tested on a separate compressed air line. If

the valve does not open at the pressure specified in section 7.3,

consult Atlas Copco.

Warning

- Never run the compressor without safety valves.

- No adjustments are allowed.

1) On 13 bar and 200 psi compressors, consult the relevant Parts

Lists for the part numbers of the filters

2) One filter on GA/GA W 90 up to -160, two filters on GA/GA W

200 up to -315.

3) See "User manual for Elektronikon regulator"

1. Filter

2. Filter chamber

3. Air inlet pipe

Fig. 15 Correct position of air filter

Loading...

Loading...