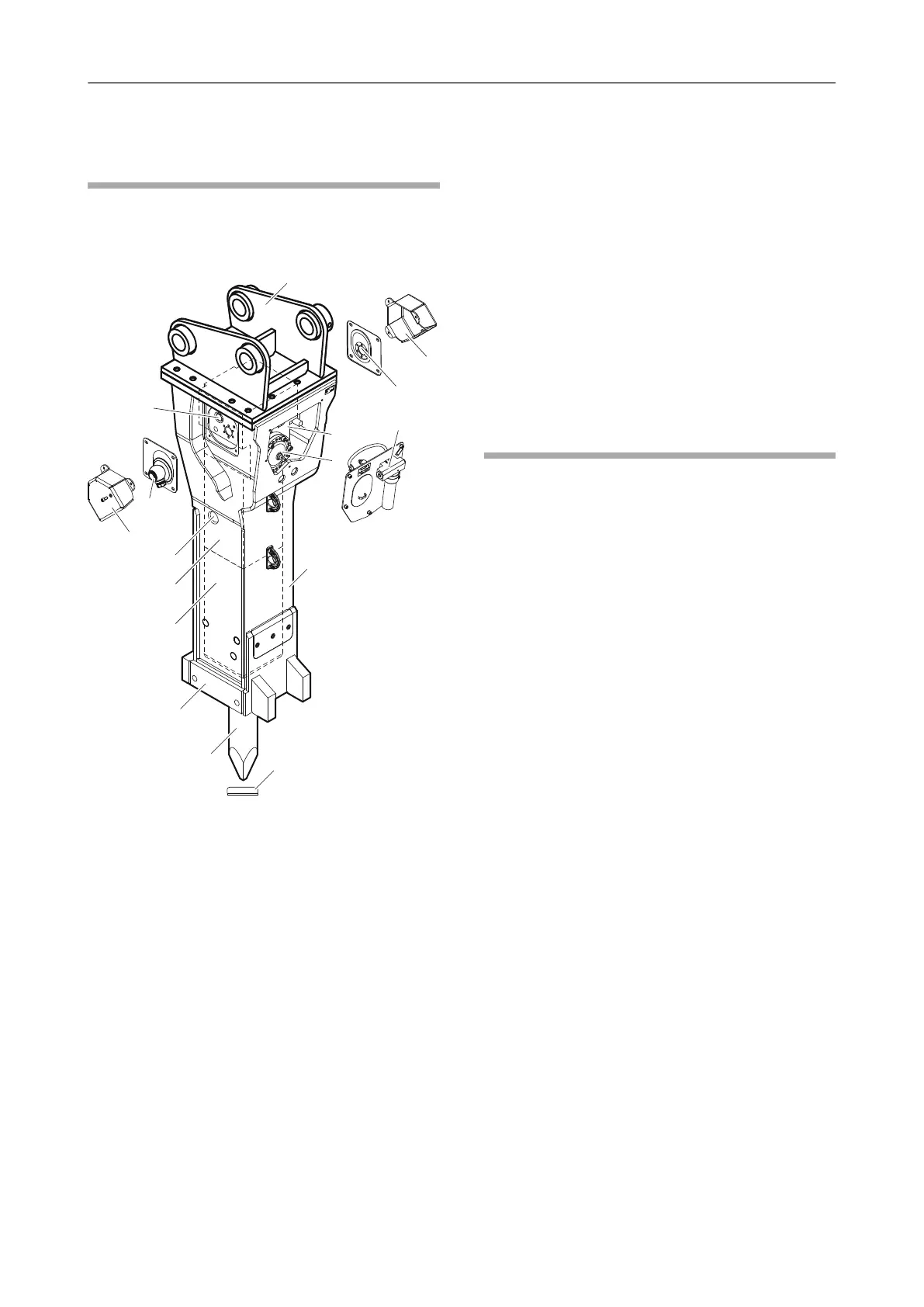

OVERVIEW

Equipment description

The picture gives an overview of the main parts and

components of the hydraulic attachment. Actual

details may differ.

A. The hydraulic breaker is connected to the

carrier by the adapter plate. The adapter plate

is not included in the scope of supply of the

hydraulic breaker.

B. Tank line »T«

C. Automatic lubrication system ContiLube

®

II

D. The cylinder cover houses the nitrogen gas

(N

2

) filled piston accumulator and the control

mechanism.

E. The HP-accumulator compensates pressure

variations in the hydraulic system.

F. The breaker box protects the percussion unit.

G. Working tool aperture protective cap

H. The working tool can be replaced as required.

The working tool is not included in the scope

of supply of the hydraulic breaker.

I. The DustProtector system prevents dust from

entering the percussion compartment (only on

the DP version).

J. The working tool is retained in the lower

breaker part.

K. The percussion piston is guided in the

cylinder.

L. StartSelect valve

M. Pressure line »P«

N. Non-return valve of percussion compartment

ventilation

O. The swivel joint covers protect the swivel

joints.

Function

The operation of a hydraulic breaker is described in

a greatly simplified version below:

The pressure line »P« supplies oil at the operating

pressure of the carrier to the hydraulic breaker. The

tank line »T« returns the oil to the tank of the carrier.

The HP-accumulator compensates pressure

variations in the hydraulic system.

The percussion piston moves up and down in the

cylinder. When the percussion piston is in its lower

position, it impacts the working tool. The percussion

energy is transferred to the material to be broken via

the working tool.

15© 2012 Atlas Copco Construction Tools GmbH | No. 3390 5096 01 | 2012-04-26

Original instructions

OVERVIEWHB 3100, 3100 DP, 3600, 3600 DP, 4100, 4100 DP,

4700, 4700 DP

Loading...

Loading...