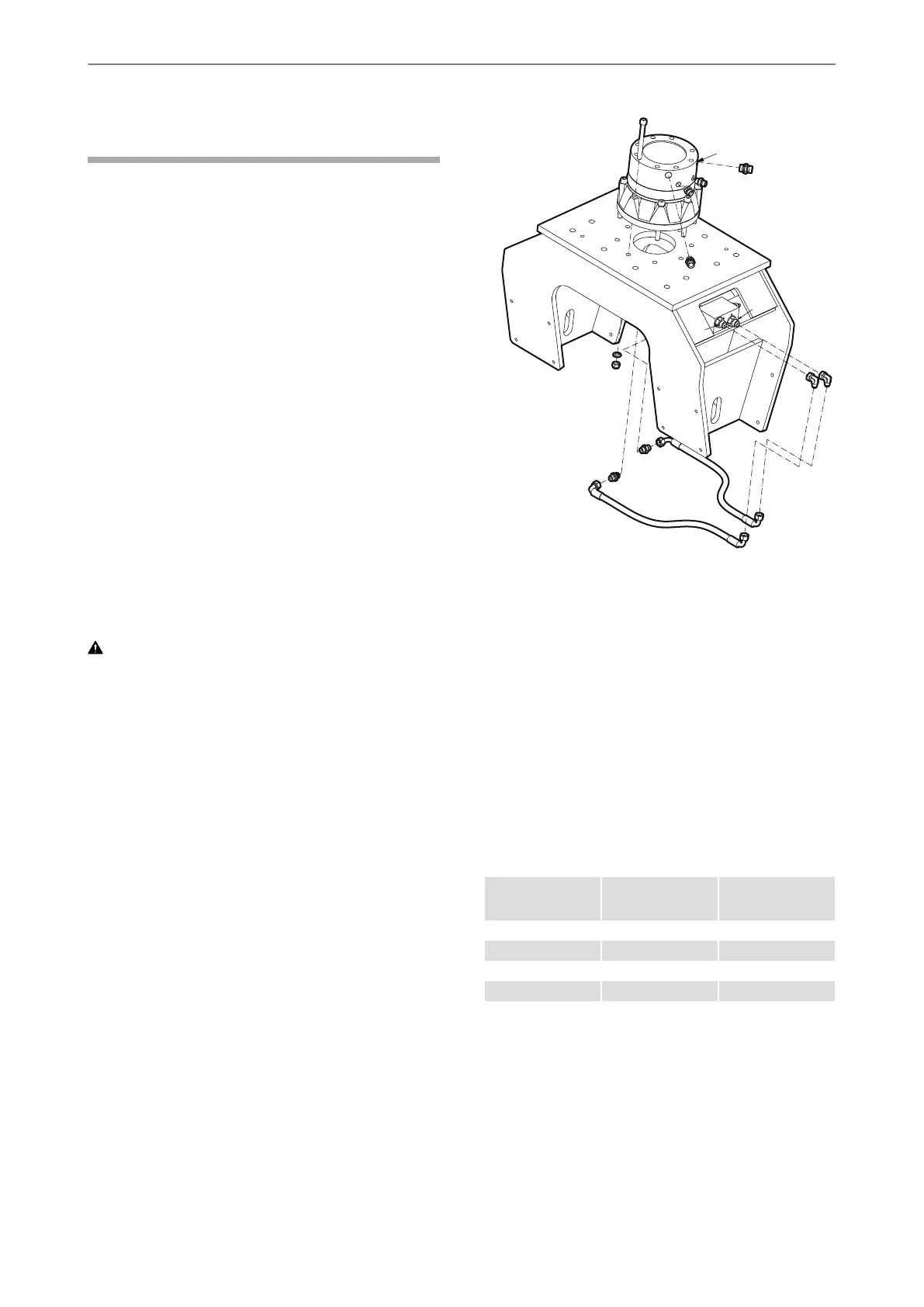

Installing the rotating

mechanism

Hydraulic compactors HC 350 to HC 1055 can be

fitted with a rotating mechanism. Install the rotating

mechanism in a workshop.

♦

Unpack the rotating mechanism and all parts

enclosed with the delivery.

♦

Remove all the packaging material.

♦

Separate the packaging materials (wood, metal,

plastic, …) and hand them in for recycling.

♦

Check that the delivery is complete.

♦

Check the delivery for visual damage.

♦

If any defects are found, consult the Atlas Copco

Customer Center/dealer in your area.

♦

Remove the hydraulic compactor from the carrier

(see chapter Removing the hydraulic attachment

from the carrier).

♦

Remove the outer housing (see the chapter

Replacing worn rubber isolators).

♦

Deposit the outer housing on level ground.

WARNING Hands and fingers being cut off

or hurt

Bores and surfaces can act like a pair of scissors

and cut off or hurt parts of your body.

► Never use your fingers to check bores or fitting

surfaces.

♦

Fit a pair of lock washers onto every screw.

♦

Insert the screws from above through the holes in

the rotating mechanism.

♦

Align the rotating mechanism so that both

connections on the oil distributor transversally

point to the outer housing.

♦

Place the rotating mechanism on the outer

housing, so that the screws slide into the holes in

the outer housing.

♦

Put a pair of lock washers on every screw from

below and screw the nuts onto the screws.

♦

Tighten the nuts with the required tightening

torque.

Tightening

torqueSpanner sizeModel

295 Nm14 / 24 mmHC 350

295 Nm14 / 24 mmHC 450

295 Nm14 / 24 mmHC 850

580 Nm17 / 30 mmHC 1050

580 Nm17 / 30 mmHC 1055

© 2014 Construction Tools EOOD | No. 3390 5121 01 | 2014-11-19

Original instructions

20

HC 150, 350, 450, 850, 1050, 1055INSTALLATION

Loading...

Loading...