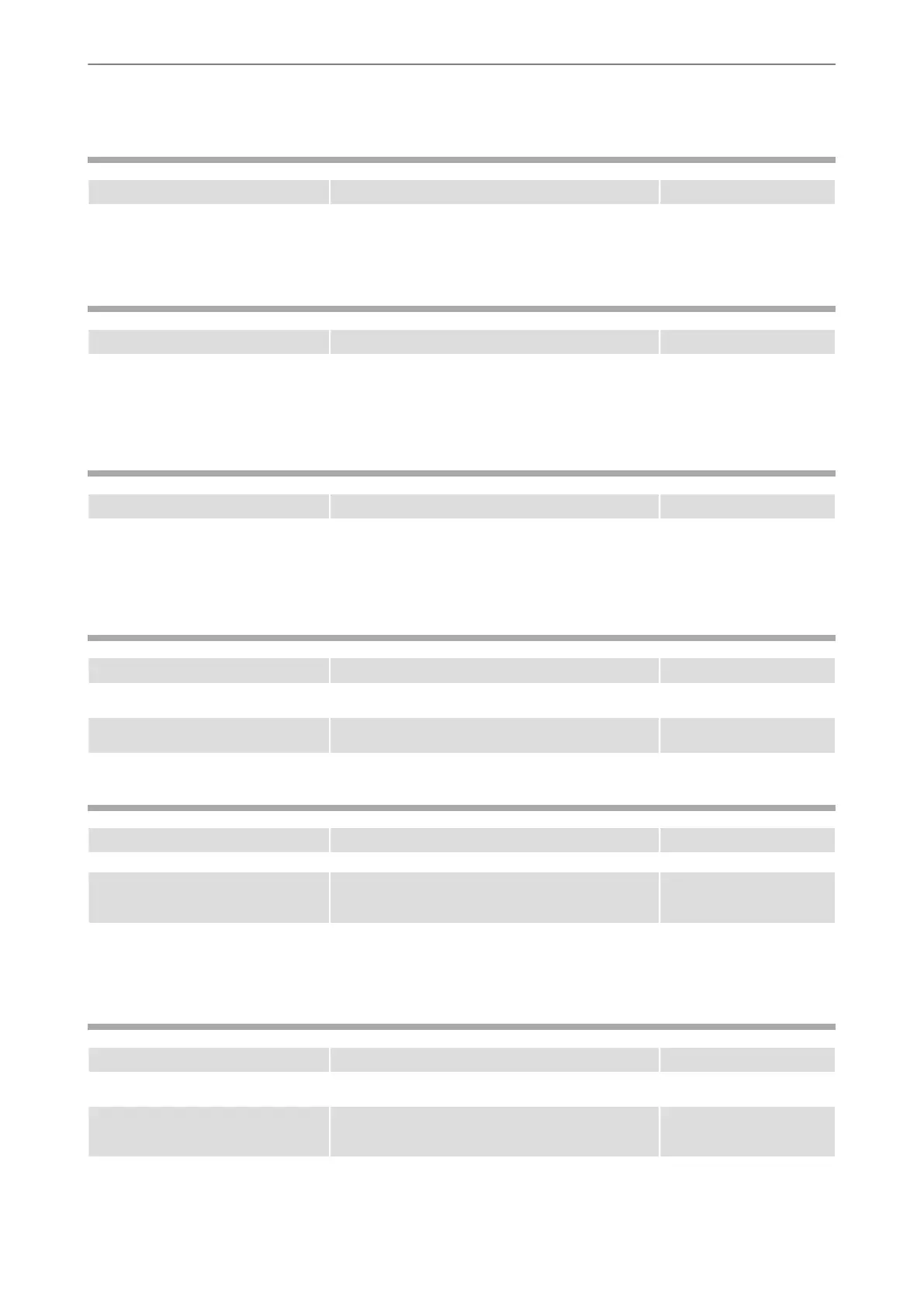

Oil escapes from the hydraulic motor (rotor and rotating

mechanism)

ByRemedyCause

Atlas Copco Customer

Center/Dealer in your area

Workshop

Seal the motor

Replace the motor

Motor damaged

Oil leaks from hydraulic ports

ByRemedyCause

Carrier driver

Tighten the cap nuts (see section Screw

connections/Tightening torques)

Cap nuts loose

Oil escapes from parts of the hydraulic attachment installation

(connecting fittings, hoses etc.)

ByRemedyCause

Carrier driver or workshopTighten the connecting fittings; replace any defective parts;

check the hydraulic attachment installation, replace any

damaged parts, only use original parts (see section Screw

connections/Tightening torques)

Connecting fittings are loose

Oil escapes from the hydraulic attachment

ByRemedyCause

Workshop

Tighten the covers see chapter (Screw

connections/Tightening torques)

Covers are loose

Workshop

Replace the O-rings (see chapter Replacing rotor and/or O-

rings of covers)

O-rings of covers defective

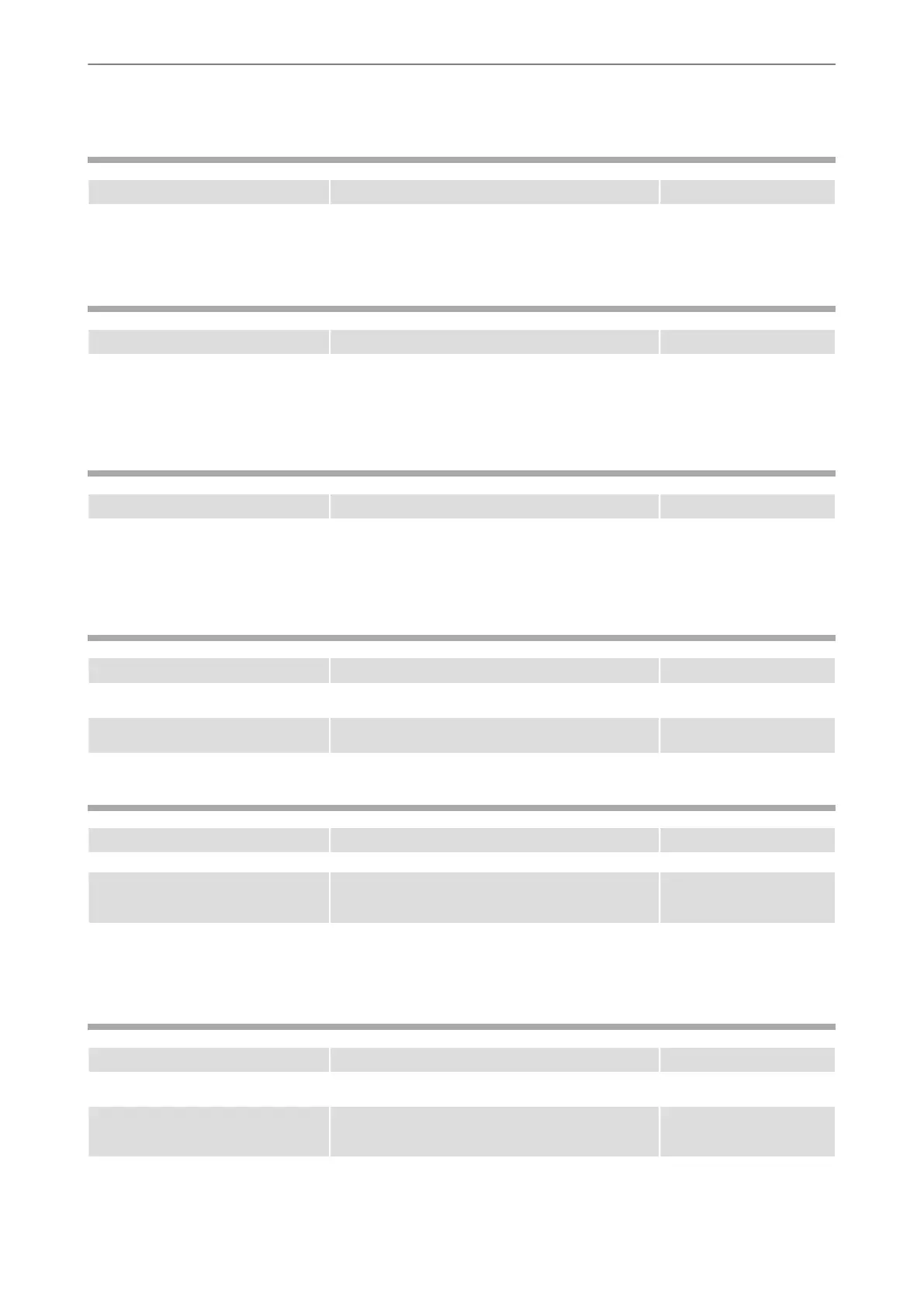

Operating temperature too high

ByRemedyCause

Carrier driver or workshopCheck oil level and top up oilOil level in tank too low

Atlas Copco Customer

Center/Dealer in your area

Check and correct motor speed of carrier

Drive the pump

Carrier pump delivery too high; a constant

volume of oil is squirted out of the pressure

relief valve

Workshop or Atlas Copco

Customer Center/Dealer in

your area

Fit new type-tested pressure relief cartridges or a more

precise pressure-limiting valve

Pressure relief valve defective or valve with

poor characteristics

The hydraulic compactor cannot be rotated

ByRemedyCause

Atlas Copco Customer

Center/Dealer in your area

Replace the defective partsRotation motor/transmission defective

Carrier driver or Service

Department of carrier

manufacturer

Check the »Rotate gripper« function of the carrier (Observe

the Operating Instructions for the carrier)

Carrier defective

© 2014 Construction Tools EOOD | No. 3390 5121 01 | 2014-11-19

Original instructions

42

HC 150, 350, 450, 850, 1050, 1055TROUBLESHOOTING

Loading...

Loading...