18 1310 3011 73

.

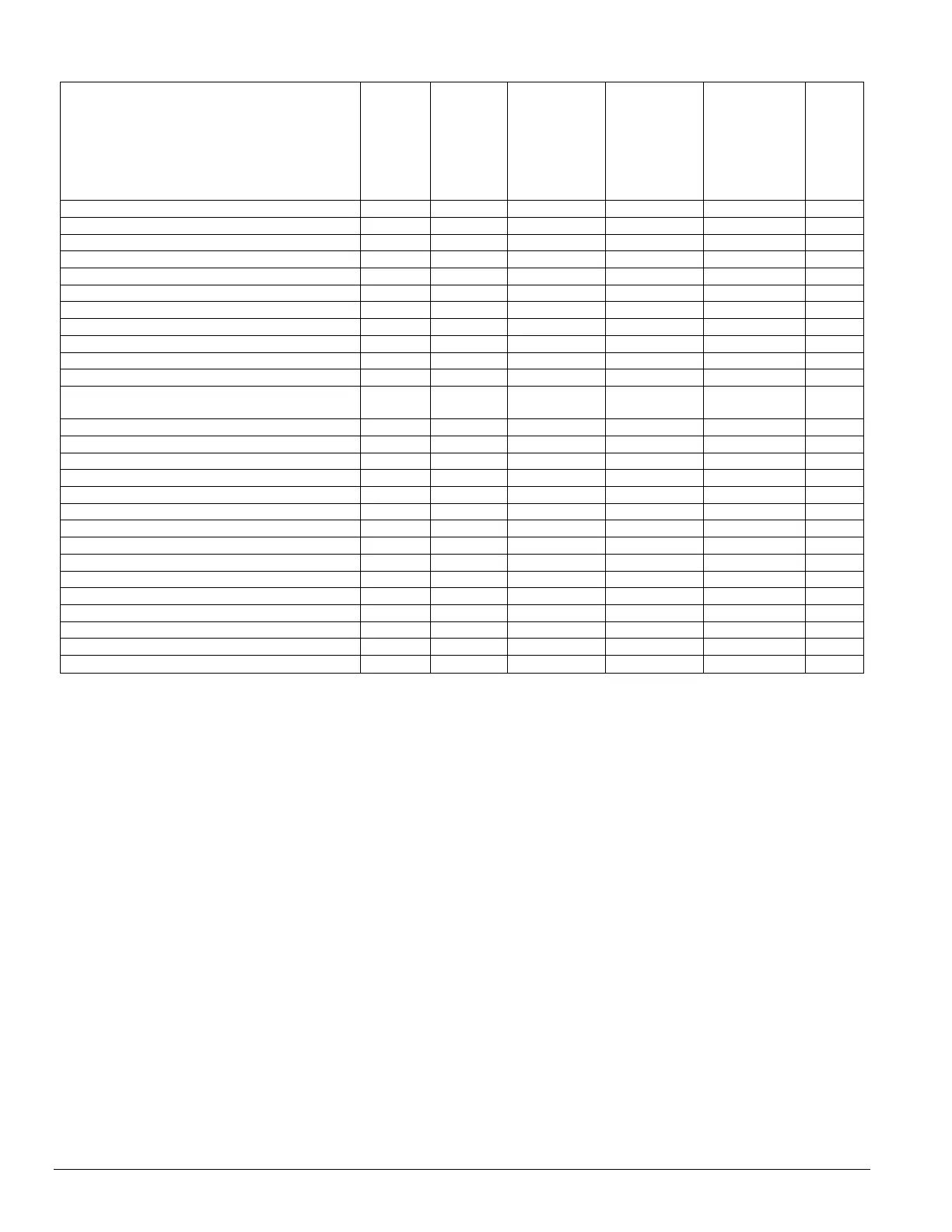

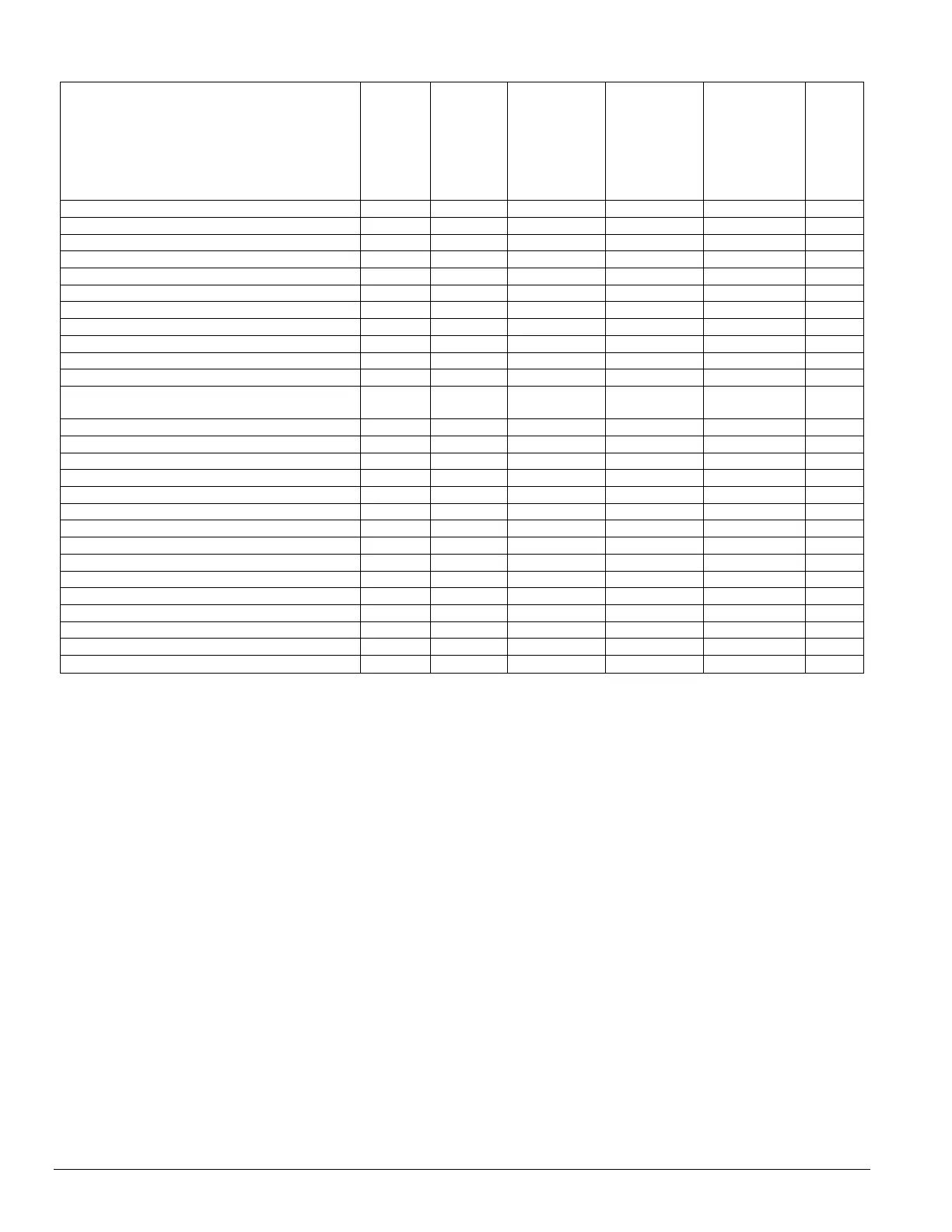

MAINTENANCE SCHEDULE Daily Initially

Around

50 hours

Normal

Or every 250

hours

Kit Part #

1310300374

Bi-Yearly

Or every 500

hours

Kit Part #

1310300375

Yearly

Or every

1000 hours

Kit Part #

1310300373

Note

Engine oil level Check

Compressor oil level Check

Air filter dust valve Empty

Fuel filter water drain Drain

Air intake vacuum indicator Check

Electrolyte level and terminals of battery Check Check Check Check

Tire pressure Check Check Check Check

Leaks in air-, oil- or fuel system Check Check Check Check

Oil cooler package Clean Clean Clean

Engine minimum and maximum speeds Check Check Check Check

Torque of wheel nuts Check Check Check Check

Brake system (if installed)

Check/

Adjust

Check/

Adjust

Check/

Adjust

Check/

Adjust

Safety valve Test

Door Hinges Grease Grease Grease

Towing eye shaft or ball coupling and its shaft Grease Grease Grease

Shut-down switches Check

Pressure drop over separator element (2) Measure Measure Replace

Fan v-belt (3) Adjust Adjust Adjust Adjust

Fuel tank Clean Clean Clean

Compressor oil Change

Compressor oil filter Replace Replace

Air filter element (1) Replace

Engine oil (3) Change Change Change Change

Engine oil filter (3) Replace Replace Replace Replace

Fuel filter (Primary and Final) (3) Replace Replace Replace

Engine intake and exhaust valves (3) Adjust Adjust

Inspection by Atlas Copco Service technician

f

(1) More frequently when operating in a dusty environment.

(2) Replace the element when the pressure drop exceeds 11.5 psi.

(3) Refer to the John Deere instruction manual.

f Keep the bolts of the housing, the lifting eye, the towbar and the axle securely tightened. Refer to

Compressor/Engine Specifications (section 7.2) for the torque values.

4.3 Lubrication oils

It is strongly recommended to use Atlas Copco branded

lubrication oils for compressor.

Compressor oil

PAROIL:

5 gallon pail: order number

1310 0334 30

Skid (24) 5 gallon pails: order number

1310 0334 32

Skid (4) 55 gallon drums: order number

1310 0334 33

+ If you want to use another brand of oil, consult

Atlas Copco for more information concerning

the recommended oil and service intervals.

4.4 Oil Level Check

f Never mix oils of different brands or types

4.4.1 Check Engine Oil Level

Consult also the Engine Operation Manual for the oil

specifications, viscosity recommendations and oil change

intervals.

See schedule.

Check engine oil level according to the instructions in the

Engine Operation Manual and top up with oil if necessary.

4.4.2 Check Compressor Oil Level

With the unit standing level, engine stopped, check the level of

the compressor oil. The pointer of the oil level gauge (OLG)

must register in the upper extremity of the green range. Add oil

via the oil fill plug (FP) if necessary.

f Before removing oil filler plug, ensure that the

pressure is released by opening an air outlet valve.

Loading...

Loading...