Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not

permitted unless authorised by AUDI AG. AUDI AG does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by AUDI AG.

Basic procedure for SG plug welds

♦ Remove spot welds with a spot weld cutter or grind them down.

♦ Detach damaged part (use a chisel if necessary).

♦ Grind down projecting material.

♦ Match up new part.

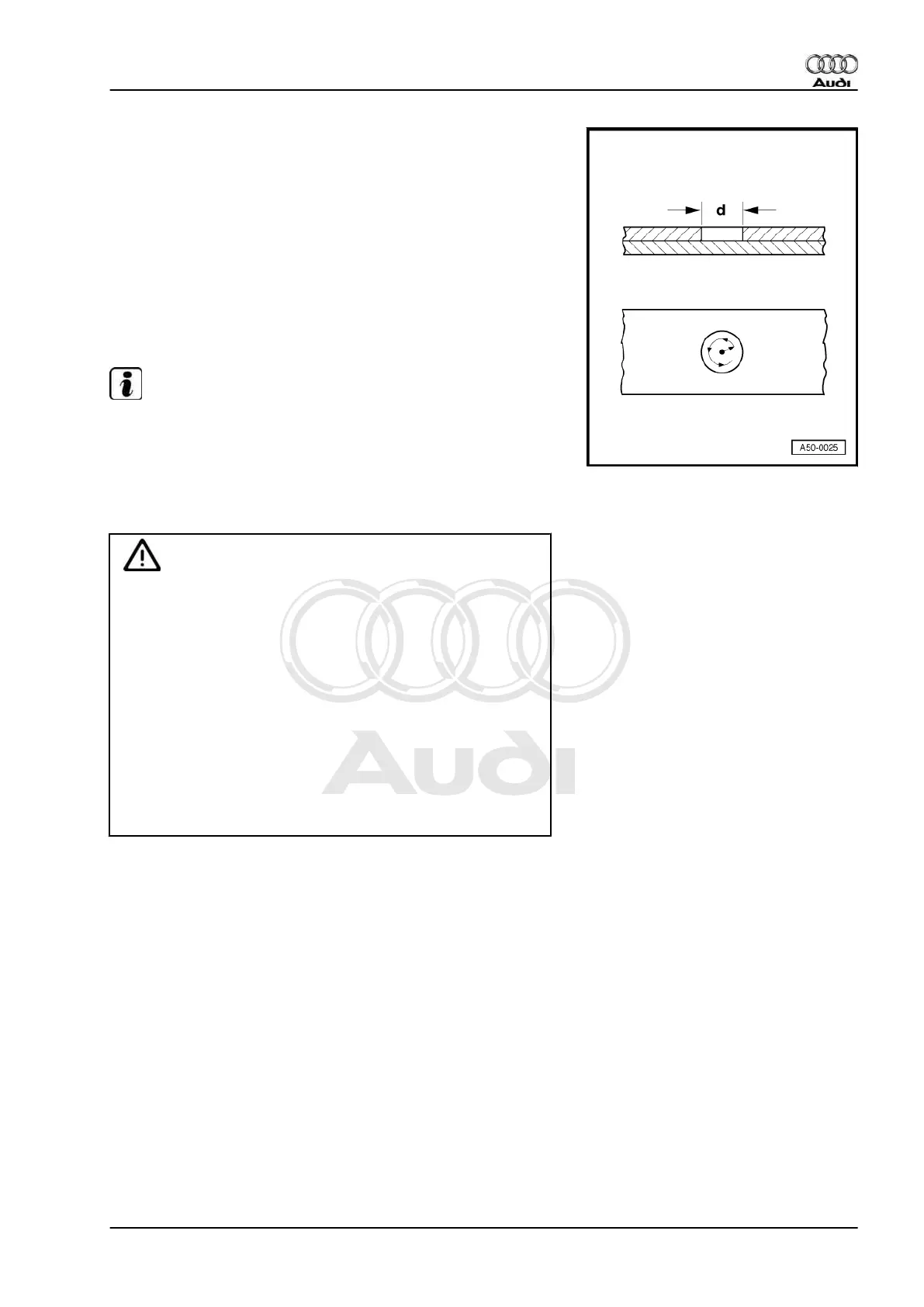

♦ Drill hole for plug weld in upper panel (for diameter, refer to

Workshop Manual for relevant vehicle).

♦ Clean flanges and remove oxide layer.

♦ Make plug weld, working outwards from centre.

Note

Riveting is also permissible in some cases. Refer to “Body Re‐

pairs” workshop manual.

Equipment

Only equipment which is listed as approved in the workshop

equipment catalogue may be used.

WARNING

♦ Always use an extraction system when performing weld‐

ing and grinding work.

♦ Welding and grinding must never be performed simulta‐

neously in the same working area.

♦ Working area must be cleaned at regular intervals as nec‐

essary to remove dust.

♦ Compressed air must NOT be used to blow out dust de‐

posits.

♦ The extraction system must be cleaned at regular inter‐

vals.

♦ In addition, the relevant accident prevention and industrial

safety regulations must be observed.

6.3 SG continuous seams and stitch weld

seams

SG continuous seams and stitch weld seams are primarily used

for joining parallel or overlapping surfaces. Due to the very high

welding temperatures and the associated change in the proper‐

ties of modern materials, the areas in which this joining technique

are used are becoming increasingly restricted. It is essential to

refer to the Workshop Manual for the relevant vehicle in such ca‐

ses.

Equipment

Only equipment which is listed as approved in the workshop

equipment catalogue may be used.

General InformationBody Repairs, General Body Repairs - Edition 04.2018

6. Thermal joining techniques 25

Loading...

Loading...