54

500 Series

7. Hydraulic oil level

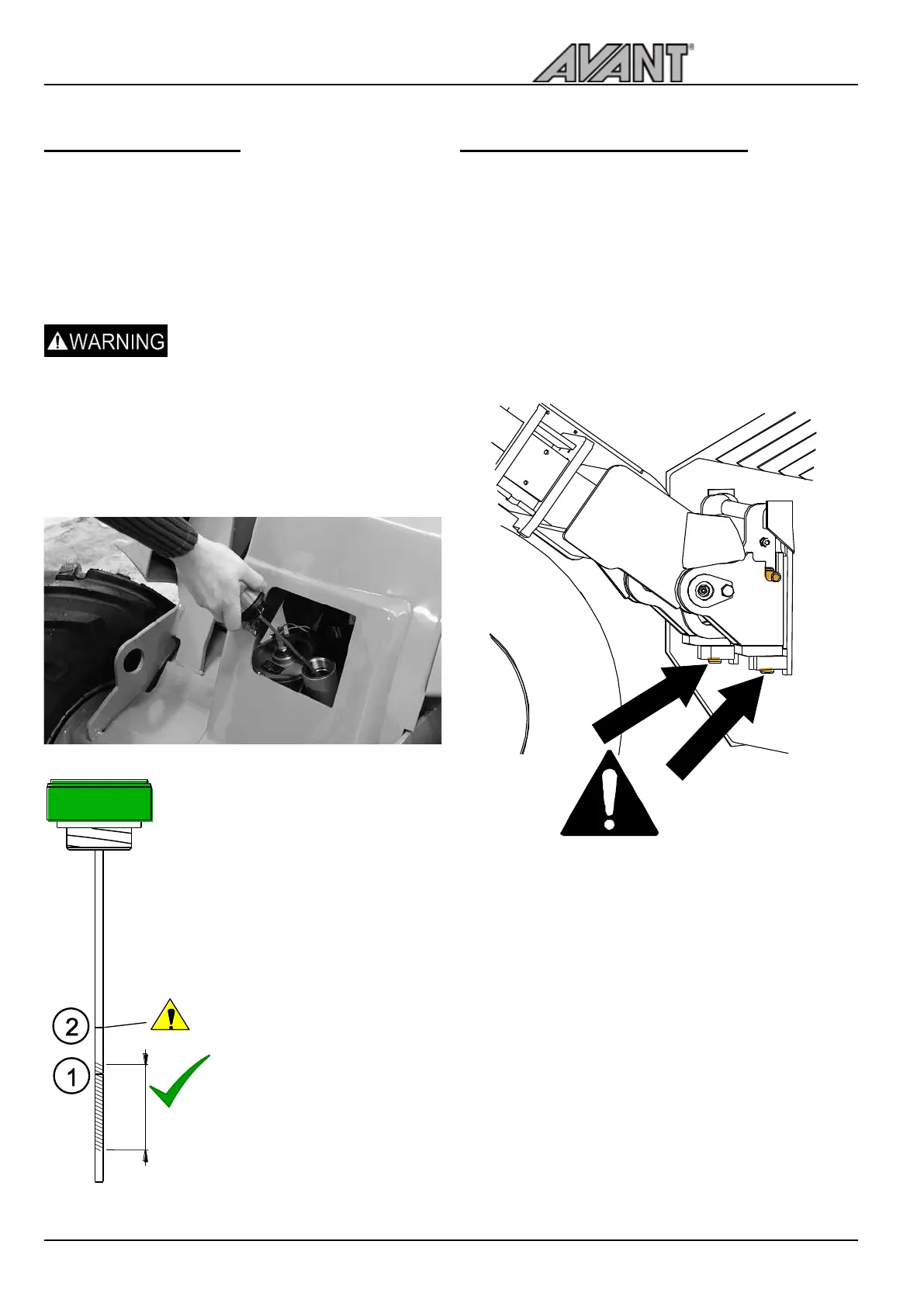

Hydraulic oil tank ller is located on the front of the boom,

under a hatch.

Hydraulic oil level can be checked with the dipstick in

the ller. Lock the boom with the boom service support

to access the ller opening. Do not let any contaminants

enter the hydraulic oil tank when you open the ller cap.

Remember to use the service

support (page 30)

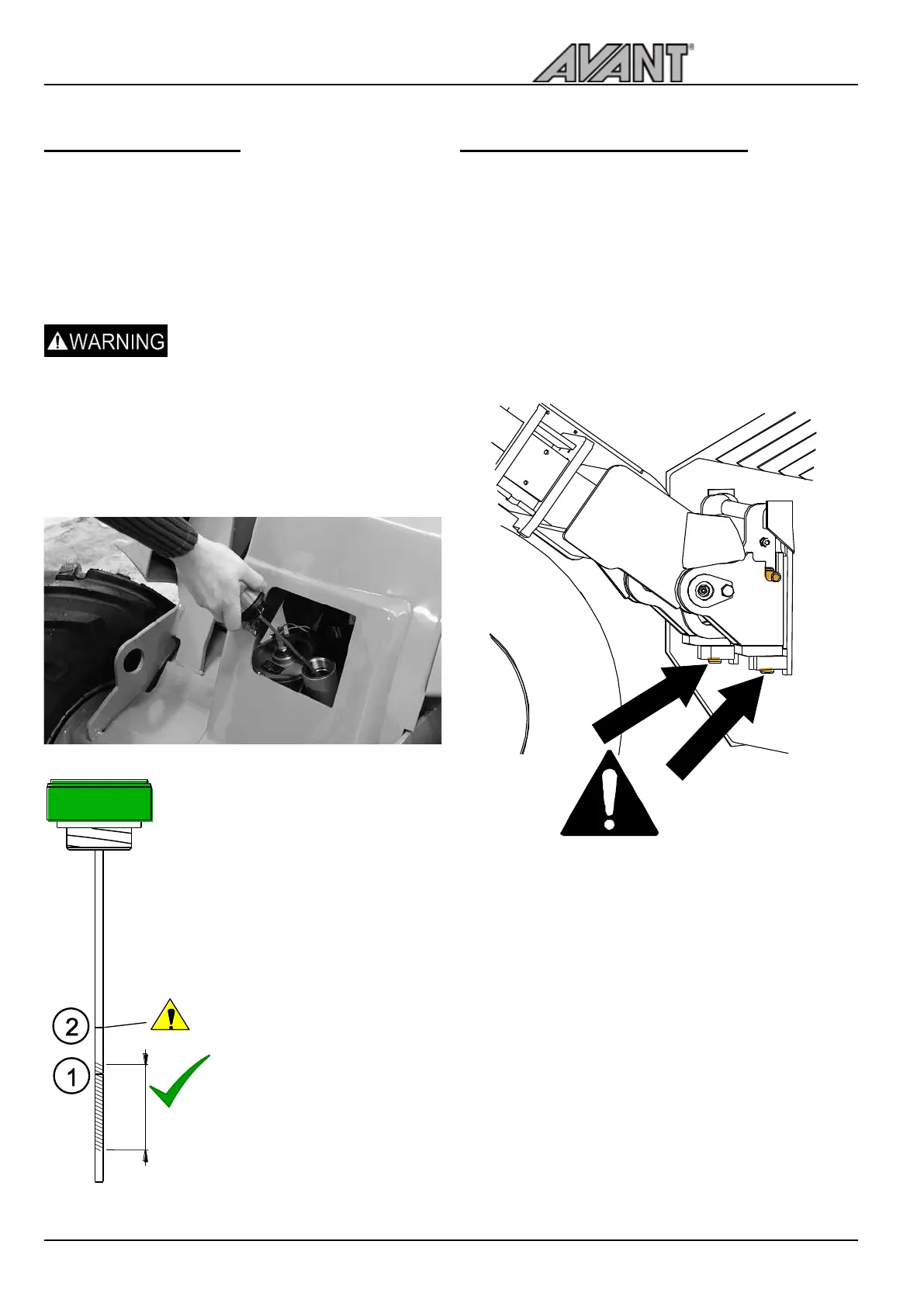

The oil level should be approximately at the lower mark of

the dipstick (1) when the loader boom is up.

Tighten the dipstick on its threads for measurement. Rell

when necessary, but never exceed the upper limit mark

(2). Overll can cause oil to overow when lowering the

boom.

1 Target marker. Fill to this

mark when hydraulic system

is cold.The area highlighted

in the adjacent gure shows

approximately the acceptable

level.

2 The second mark on the

dipstick indicates the max

level of hydraulic oil. Oil can

reach this level when the

hydraulic system is hot.

Never overll the hydraulic oil

tank. Oil can ow over, or foam

inside the tank.

There is a breather lter inside

the dipstick cap which should

be cleaned or changed once a

year.

8. Attachment and its locking

Check the locking of attachment and function of the

locking pins of the attachment quick coupling plate.

• Both pins must move and come through the lower

brackets of the attachments.

• To check the correct function of the attachment

and itsadditional coupling instructions, see the

Operator’smanual of the corresponding attachment.

Do not operate the loader if the coupling pins do not

lock down. Always keep the Operator’s manual of each

attachment available.

Engine inspections and maintenance

Loading...

Loading...