E3

z I/O isolation

Items surrounded by solid lines are insulated from other signals.

Availability of input or output is based on a model number.

Power supply

Internal

Circuit

Control output 1

Control output 2

PV input

Current transformer input 1

Current transformer input 2

Motor feedback input

Loader communication

Auxiliary output

Digital input 1

Digital input 2

Digital input 3

Digital input 4

RS-485 communication

Event output 1*

Event output 2*

Event output 3

RSP input

* In case of independent contact, the part between the event

output 1 and the event output 2 is isolated.

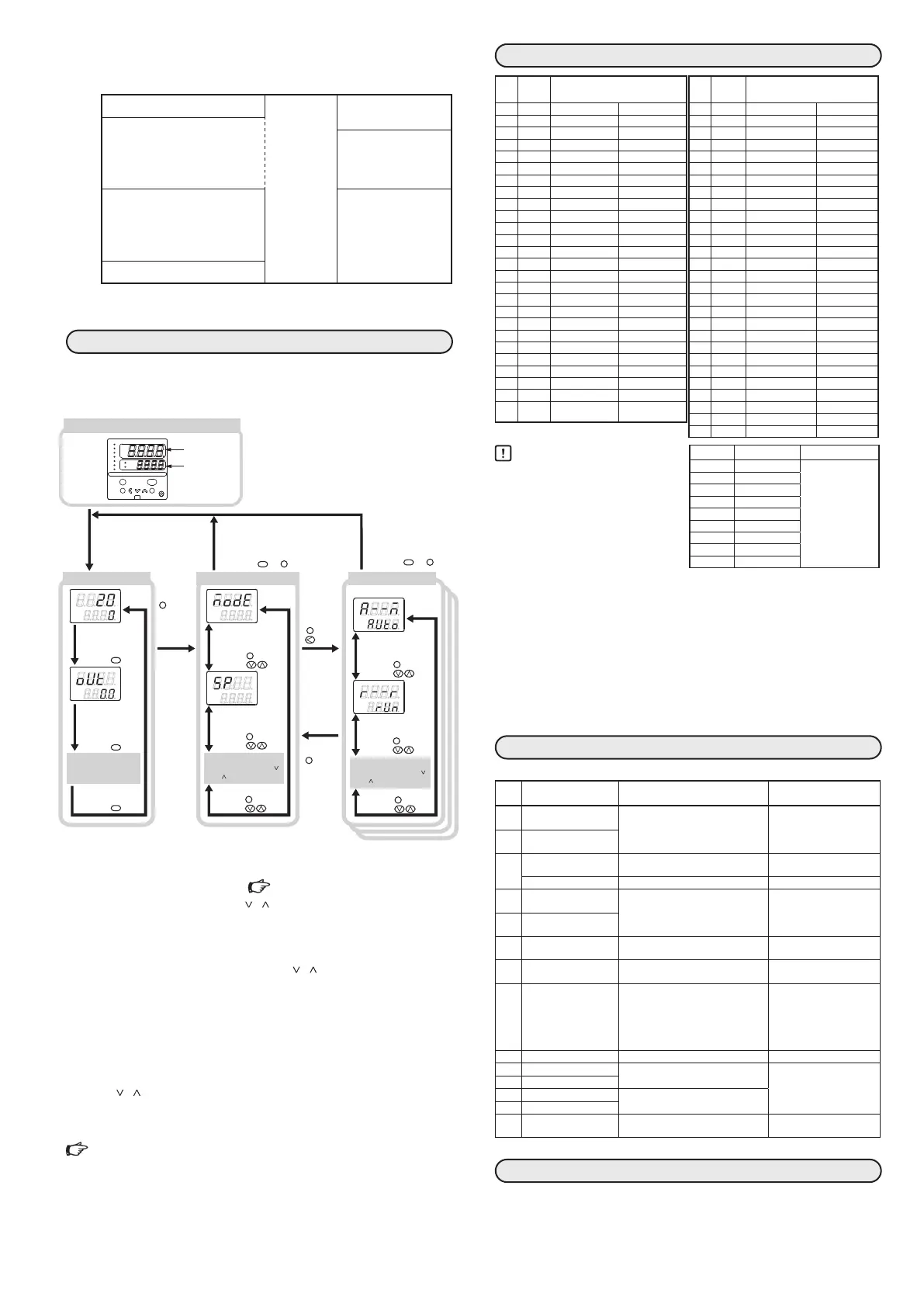

SETTING THE PV RANGE TYPE

z Flowchart of key operations

There are the standard type and special type in the data setup

method. Here, the method is explained in the standard type.

Operation display Bank selection display Bank setup display

mode

display

enter

para

man

rsp

ev1

ev2

ev3

ot1

ot2

sp

out

pv

SDC36

The mode indicators are lit sequentially form

the left during a period of 5 to 6 sec after the

power has been turned ON while both the

upper display and lower display are OFF.

When all mode indicators have been lit, the

display is changed to the operation display.

(example. mode bank)

OFF

OFF

Display when the power is turned ON.

The display and setup status shown above are examples for explanation.

Therefore, some displays or settings are not shown actually according to

the model and/or setup contents.

No key operation for 3 minutes

or more.

mode

Press the or key.

display

No key operation for

3 minutes or more.

enter

Press the

or

key.

Keep the

key

pressed

for 2 sec.

or longer.

para

Mode bank selection

SP bank selection

Other display and setup

(Operate the [display]

key repeatedly.)

PV/SP display

display

key.Press the

display

key.Press the

display

key.Press the

MV display

para

key.Press the

key.Press the

para

key.Press the

key.Press the

para

key.Press the

key.Press the

para

key.Press the

key.Press the

Other banks

(Operate the [para], [ ]

and [ ] keys repeatedly.)

AUTO/MANUAL

change

RUN/READY change

para

key.Press the

key.Press the

para

key.Press the

key.Press the

Other setup

(Operate the [para], [ ]

and [ ] keys repeatedly.)

mode

Press the or key.

display

Keep the

key

pressed

for 2 sec.

or longer.

para

Step 3. Setting the PV range ( PV RANGE TABLE)

In the mode bank MOdE, press the [

] [ ] keys to display the setup bank

Stup, and then press the [enter] key.

>> C0 1 will be displayed on the upper display. Press the [enter] key again.

>> The lower display will be flashing.

Referring to the PV range table, press the [<] [

] [ ] keys to display the de-

sired sensor type for C0 1.

Press the [enter] key.

>> The flashing will stop and the settings will go into effect.

Step 4. Setting the SP

In the mode bank MOdE, press the [enter] key.

>> The lower display will be flashing.

Press the [

] [ ] keys to display the desired SP setting.

Press the [enter] key.

>> The flashing will stop and the settings will go into effect.

Single Loop Controller Model C35/36 User’s Manual for

Installation & Configuration CP-SP-1150E and Quick Reference

Guide for Model C35/36 CP-SP-1203E.

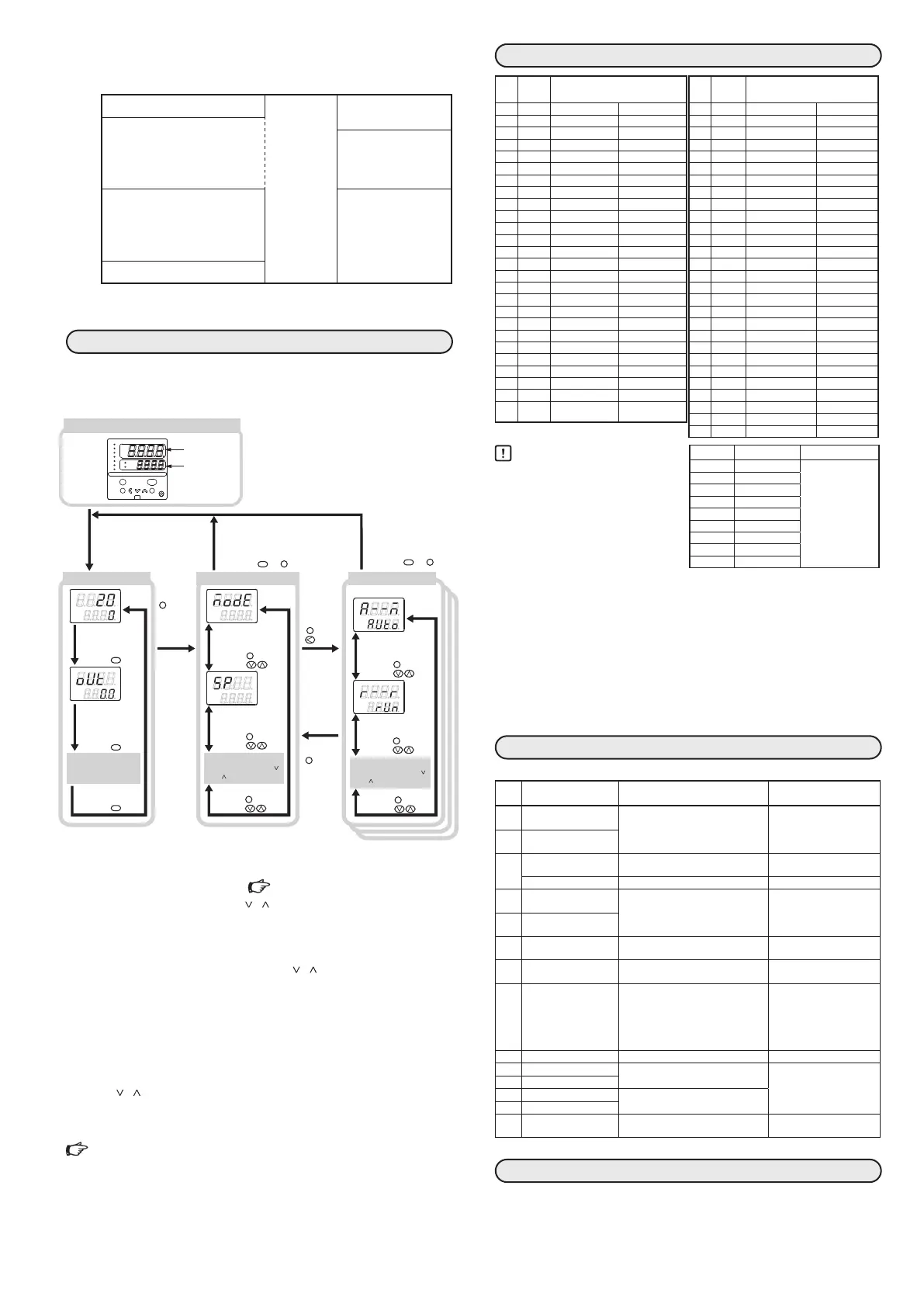

PV RANGE TABLE

C0

1

set

value

Input

type

Range

1 K −200 to +1200°C −300 to +2200°F

2 K 0 to 1200°C 0 to 2200°F

3 K 0.0 to 800.0°C 0 to 1500°F

4 K 0.0 to 600.0°C 0 to 1100°F

5 K 0.0 to 400.0°C 0 to 700°F

6 K −200.0 to +400.0°C −300 to +700°F

7 K −200.0 to +200.0°C −300 to +400°F

8 J 0 to 1200°C 0 to 2200°F

9 J 0.0 to 800.0°C 0 to 1500°F

10 J 0.0 to 600.0°C 0 to 1100°F

11 J −200.0 to +400.0°C −300 to +700°F

12 E 0.0 to 800.0°C 0 to 1500°F

13 E 0.0 to 600.0°C 0 to 1100°F

14 T −200.0 to +400.0°C −300 to +700°F

15 R 0 to 1600°C 0 to 3000°F

16 S 0 to 1600°C 0 to 3000°F

17 B 0 to 1800°C 0 to 3300°F

18 N 0 to 1300°C 0 to 2300°F

19 PLII 0 to 1300°C 0 to 2300°F

20 Wre5-26 0 to 1400°C 0 to 2400°F

21 Wre5-26 0 to 2300°C 0 to 4200°F

22 Ni-Ni·Mo 0 to 1300°C 0 to 2300°F

23 PR40-20 0 to 1900°C 0 to 3400°F

24 DIN U −200.0 to +400.0°C −300 to +700°F

25 DIN L −100.0 to +800.0°C −150 to +1500°F

26 Gold iron

chromel

0.0K to 360.0K 0 to 360K

C0

1

set

value

Input

type

Range

41 Pt100 −200.0 to +500.0°C −300 to +900°F

42 JPt100 −200.0 to +500.0°C −300 to +900°F

43 Pt100 −200.0 to +200.0°C −300 to +400°F

44 JPt100 −200.0 to +200.0°C −300 to +400°F

45 Pt100 −100.0 to +300.0°C −150 to +500°F

46 JPt100 −100.0 to +300.0°C −150 to +500°F

47 Pt100 −100.0 to +200.0°C −150 to +400°F

48 JPt100 −100.0 to +200.0°C −150 to +400°F

49 Pt100 −100.0 to +150.0°C −150 to +300°F

50 JPt100 −100.0 to +150.0°C −150 to +300°F

51 Pt100 −50.0 to +200.0°C −50 to +400°F

52 JPt100 −50.0 to +200.0°C −50 to +400°F

53 Pt100 −50.0 to +100.0°C −50 to +200°F

54 JPt100 −50.0 to +100.0°C −50 to +200°F

55 Pt100 −60.0 to +40.0°C −60 to +100°F

56 JPt100 −60.0 to +40.0°C −60 to +100°F

57 Pt100 −40.0 to +60.0°C −40 to +140°F

58 JPt100 −40.0 to +60.0°C −40 to +140°F

59 Pt100 −10.00 to +60.00°C −10 to +140°F

60 JPt100 −10.00 to +60.00°C −10 to +140°F

61 Pt100 0.0 to 100.0°C 0 to 200°F

62 JPt100 0.0 to 100.0°C 0 to 200°F

63 Pt100 0.0 to 200.0°C 0 to 400°F

64 JPt100 0.0 to 200.0°C 0 to 400°F

65 Pt100 0.0 to 300.0°C 0 to 500°F

66 JPt100 0.0 to 300.0°C 0 to 500°F

67 Pt100 0.0 to 500.0°C 0 to 900°F

68 JPt100 0.0 to 500.0°C 0 to 900°F

Handling Precautions

•

The accuracy varies according to

the range. The accuracy of the B

thermocouple is ±4.0%FS for a

range of 260°C or less, ±0.4%FS

for 260 to 800°C and ±0.2%FS for

800 to 1800°C.

The PV values under 20°C are not

shown. The accuracy of the No.15

(sensor type R) or No.16 (sensor type

S) is ±0.2%FS for a range of 100°C or less, and ±0.15%FS for 100 to 1600°C.

The accuracy of the No.23 (sensor type PR40-20) is ±2.5%FS for 0 to of

300°C, and ±1.5%FS for 300 to 800°C, ±0.5%FS for 800 to of 1900°C.

The accuracy of the No.26 (sensor type gold iron chromel) is ±1.5K.

The accuracy of the No. 55 to 62 and 81 are ±0.15%FS ±1digit for each

ranges. The accuracy of the No.19 (sensor type PLII) in the range of 0 to

32°F does not meet the indication accuracy.

•

The ranges with a decimal point show figures under decimal point.

•

Make sure to set the correct number in setup display C0 1, according to

the type and range of the sensor used. If the setting is wrong, problems

such as large temperature errors in the output may occur.

ALARM CODE TABLE

This table shows the alarm display and measures for the abnormal operation of this controller.

Alarm

code

Error Cause Corrective action

AL01

PV input failure

(over range)

Sensor line break, incorrect wiring,

incorrect PV range type setting

Checking wiring or reset PV

range type.

AL02

PV input failure

(under range)

AL03

CJ failure Terminal temperature is faulty

(thermocouple).

Checking the ambient

temperature.

PV input failure Sensor line break, incorrect wiring (RTD) Checking wiring.

AL05

RSP input failure *

1

(over range)

Sensor line break, incorrect wiring,

incorrect RSP range setting

Checking wiring or reset RSP

range code.

AL06

RSP input failure *

1

(under range)

AL07

MFB input failure Motor line break, incorrect wiring Checking wiring or conrm

the MFB input.

AL10

Motor adjustment failure Motor line break, incorrect wiring,

motor power supply failure.

Checking wiring, conrm the

motor power supply, reset.

AL11

CT input failure

(over-range)

(CT input 1 or 2, or both)

A current exceeding the upper limit of

the display range was measured. The

number of CT turns or the number of

CT power wire loops is incorrectly set,

or wiring is incorrect.

Use a CT with the correct

number of turns for the dis

-

play range, reset the number

of CT turns, reset the number

of CT power wire loops,

and/or check the wiring.

AL70

A/D conversion failure Defective A/D converter Replace unit.

AL95

Parameter failure Power turned OFF during xing data

Data corrupted due to noise, etc.

Re-start the system.

Reset data or replace unit.

(AL95/97: setting data,

AL96/98: tuning data)

AL96

Adjustment data

AL97

Parameter failure *

2

Data corrupted due to noise, etc.

AL98

Adjustment data failure *

2

AL99

ROM failure ROM (memory) error Re-start the system.

Replace unit.

*1. Displays in RSP mode *2. RAM area

MAINTENANCE

Cleaning:

When wiping out the SDC35/36, use the soft and dried cloth. Do not

use a detergent or an organic solvent like thinner or benzene.

Parts replacement: Do not replace the parts.

Fuse replacement: On AC models, when replacing the fuse for the power, make sure

that the replacement fuse complies with applicable standards. Use a

time lag fuse (T) compliant with IEC127 and rated at 250V, 0.5A.

C0

1

set value

Input type Range

81 0 to 10mV The scaling and

the decimal point

position can be

changed variably in

a range of −1999 to

+9999.

82 −10 to +10mV

83 0 to 100mV

84 0 to 1V

86 1 to 5V

87 0 to 5V

88 0 to 10V

89 0 to 20mA

90 4 to 20mA

Loading...

Loading...