WWW.BALTIMOREAIRCOIL.COM

11

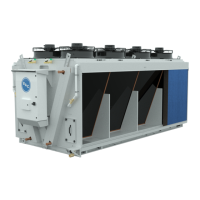

TRILLIUMSERIES™ ADIABATIC PRODUCT

Installation

3

Refrigerant Connection and Fluid Connections

The Pre-Cooler Pads represents the only potential flammable component of the

TrilliumSeries™ Adiabatic Product. Remove the first two Pre-Cooler Pads on each side

of the unit closest to the coil connection end on each side prior to brazing or welding the

refrigerant or fluid piping.

For TrilliumSeries™ Condenser units, each unit must be piped with a trapped drop leg as

shown in Figure 12. To ensure the unit operates with full capacity ensure that the drop

leg is tall enough so the column of liquid has a static pressure greater than the pressure

drop through the coil. This will be particularly important on multi-unit installations. Typical

pressure drops through microchannel coils for TSDC are 5-6 psi for HFCs and 2 psi for

NH

3

, which correspond to ~10 foot drop leg heights, although this will vary with unit sizing

and application. For TSDC HFC’s in tube/fin coils the typical pressure drop is ~ 2 psi. For

TSDC CO

2

coils, the pressure drop is 4-12 psi. For TSDC2 the maximum allowed pressure

drops is 12 psi for water, 10 psi for CO

2

, 1 psi for NH

3

and 3 psi for HFCs. Contact BAC

for special selections that may fall outside of these parameters.

NOTICE:

1. Weld/braze the pipes with care,

noting that the coil itself may

be aluminum. Protect the PVC

piping and any exposed wiring

from weld splatter.

2. Vacuum and clean all

copper dust.

3. When piping the refrigerant

connections, take care not to

block the door opening of the

access hatch or control panel.

4. For units equipped with

threaded connections, be sure

not to apply all torque directly

to the header as this may cause

damage and leaks.

5. Connections for fluid coolers

are available in red brass MPT,

flanged, or copper sweat. Always

follow best practices when

connecting refrigerant or fluid

connections.

Figure 12. Refrigerant Connection

Equalizing Line

Compressor Discharge

Liquid to System

Receiver

Condenser

Relief Valve

Piping with Top Inlet Receiver Using Ammonia or CO2

Supply of valves and fittings beyond these points

are supplied and installed by others.

Refrigerant Ball

Valves

Field Supplied and

Installed Charge &

Purge Valves

Relief Valve

Drop Leg

Discharge Line

NOTE: If you are unable to pipe an

adequate drop leg, the discharge

line can be piped to the bottom of

the receiver.

Loading...

Loading...