WWW.BALTIMOREAIRCOIL.COM

5

Unit Weights

Before rigging any unit, the weight should be verified from the unit submittal drawing.

Anchoring

For the TSDC, 7/8” diameter holes are provided in the bottom flanges of the unit for

bolting the unit to the support beams. Refer to the suggested support drawing included

in the submittal for location and quantity of the mounting holes. The unit must be level

in both length and width directions for proper operation (max 1/16”/ft for the TSDC2 and

TSDF2). Anchor bolts must be provided by others, BAC recommends 3/4” bolt SAE J429

Grade 5, ASME A325 Type 1 or equivalent. If vibration isolated supports are to be used,

the units shall be installed on steel support first and the vibration isolators (provided

by others) should be mounted under the steel support. Refer to the vibration isolation

manufacturer’s guidelines before loading/unloading weight from the unit.

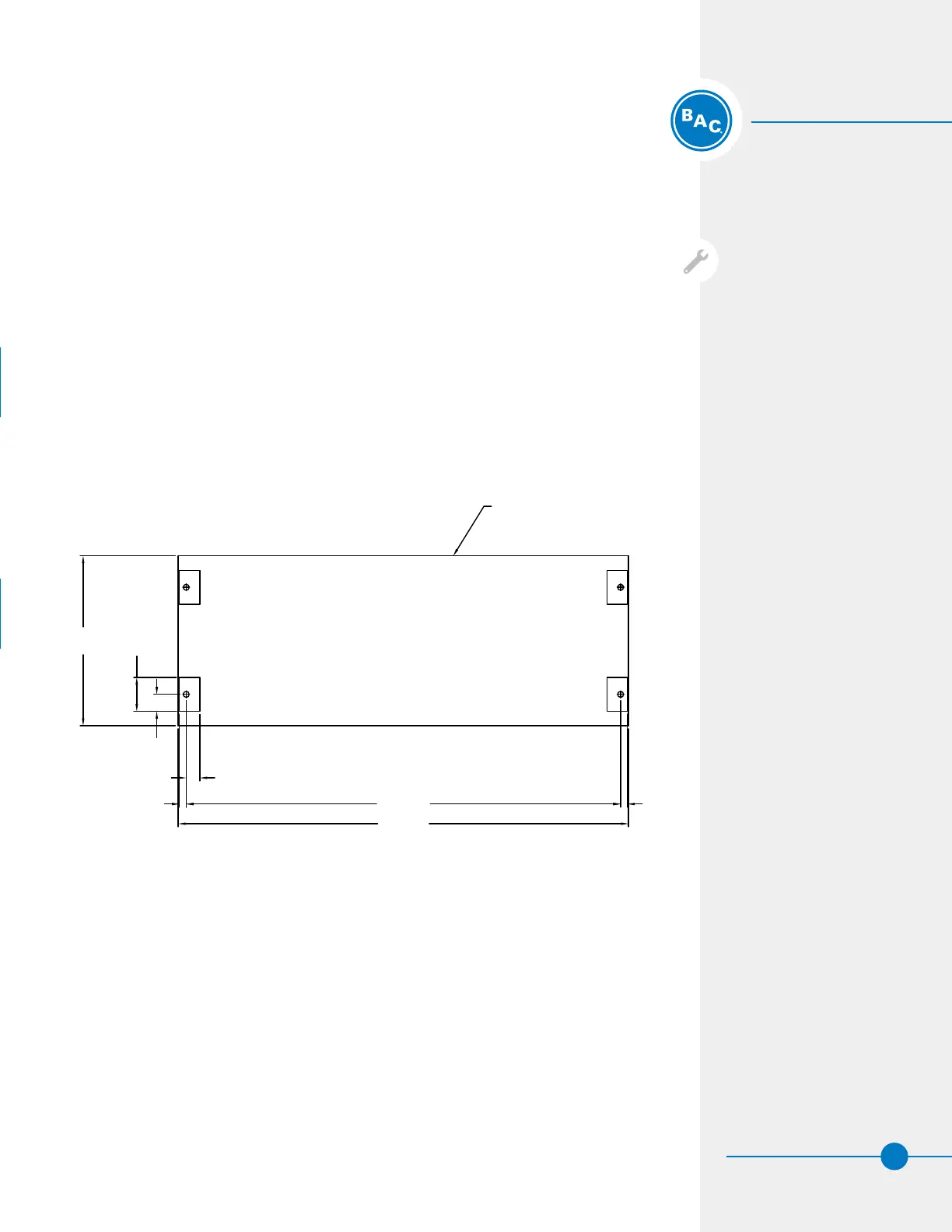

Point Support for Curb Mounting (For TSDC Only)

If mounting a TrilliumSeries™ Adiabatic Product on a curb, follow Figure 2 below for point

support locations.

NOTICE: Before an actual lift is

undertaken, open the access hatch

and check to ensure no water, snow,

ice, or debris has collected in the

sump or elsewhere in the unit. Such

accumulations will substantially

add to the equipment’s lifting

weight.

UNIT OUTLINE

AIR INLET

11'-0 1/2"

4'-2"

PLAN VIEW

AIR INLET

10'-7 7/8"

2" MIN

4" MIN

5"

10" MIN

CONNECTION END

POINT 1

POINT 2

POINT 3

POINT 4

2" MIN

Figure 2. Unit Point Support for Curb Installation (TSDC Only)

Rigging

Safety

Pre-Rigging Checks

Unit Weights

Anchoring

Loading...

Loading...