8 english

2.5.2 IECEx certificate of conformity

The BTLs have been certified under certificate number

IECEx SIR 11.0048X. The current issue of the certificate

and further information can be found in the “Certified

Equipment Scheme” section at www.iecex.com.

The certificate number is indicated on the part label.

2.5.3 Special conditions (“X” symbol)

The “X” symbol indicates special conditions that must be

noted for safe operation:

– The permissible ambient temperature is limited to

–50°C…+80°C.

– The certification of this equipment relies upon the

following materials used in its construction:

– Flange – stainless steel

– Cover – stainless steel

– O-ring

If the equipment is likely to come into contact with

aggressive substances, then it is the responsibility of

the user to take suitable precautions that prevent it

from being adversely affected, thus ensuring that the

type of protection featured by the equipment is not

compromised.

Aggressive substances: e.g. acidic liquids or gases that

may attack metals, or solvents that may affect

polymeric materials.

Suitable precautions: e.g. regular checks as part of

routine inspections or establishing from the material’s

data sheets that it is resistant to specific chemicals.

– The picture of the product label in section 14.2 of this

document has to be checked for appropriate markings,

ratings, and manufacturer contact information.

2.5.4 Operator documents

Zone classification in the system is the responsibility of the

operator and must be documented in an explosion

protection document. This document must also contain

the hazard analysis and assessment, proof of training,

maintenance plans and other documents as required

under Directive 1999/92/EC.

We expressly recommend including the user’s guide in the

operator’s documentation. For safety reasons, it must be

taken over completely and without any changes.

2

EX safety notes (continued)

2.6 Assembly, installation, and setup

Assembly, installation, and setup of the BTL must not be

done in an explosive atmosphere.

The mounting distance between the flanged joint and solid

objects which are not part of the equipment must be at

least 2mm.

The calibration box (Accessories) may only be installed

during the adjustment phase and must be uninstalled

before operating the BTL.

Protect the

BTL

from damage and wear. In addition to

mechanical protection, this also includes precautions to

prevent non-permissible operating conditions and damage

due to environmental influences.

2.7 Maintenance, inspection, repair

The measuring principle used in this BTL is maintenance-

free and wear-free. The operator must regularly inspect the

BTLs for signs of damage or malfunctions in line with the

operating conditions and environmental influences. If any

damage or wear is found, the BTL must be immediately

taken out of operation.

Only Balluff service technicians may repair defective BTL.

Intervention in the product by the operator is not permitted

due to safety reasons.

A warning is included on the part label.

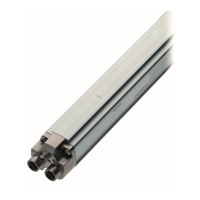

BTL7-A/C/E/G5_ _-M_ _ _ _-J-DEXC-TA12

Magnetostrictive Linear Position Sensor – Rod Style

Type of protection “db” and “ta”

Flameproof enclosure

Loading...

Loading...