20 english

6

Calibration procedure (continued)

6.5 Calibration procedure notes

Prerequisites

– The programming inputs are connected or the

calibration device is in place.

– The BTL is connected to the system controller.

– Voltage or current values from the BTL can be read

(using a multimeter, the system control or the adjusting

box).

Values for null and end point

– Any desired position of the magnet can be used as the

null or end point. However, the null and end points may

not be reversed.

– The absolute null and end points must lie within the

minimum or maximum range of what can be output

(see value table).

– The distance between the null point and end point

must be at least 4mm.

The last set values are always saved, regardless

of whether the setting was ended using the

buttons, the programming inputs or

automatically after 10min have expired.

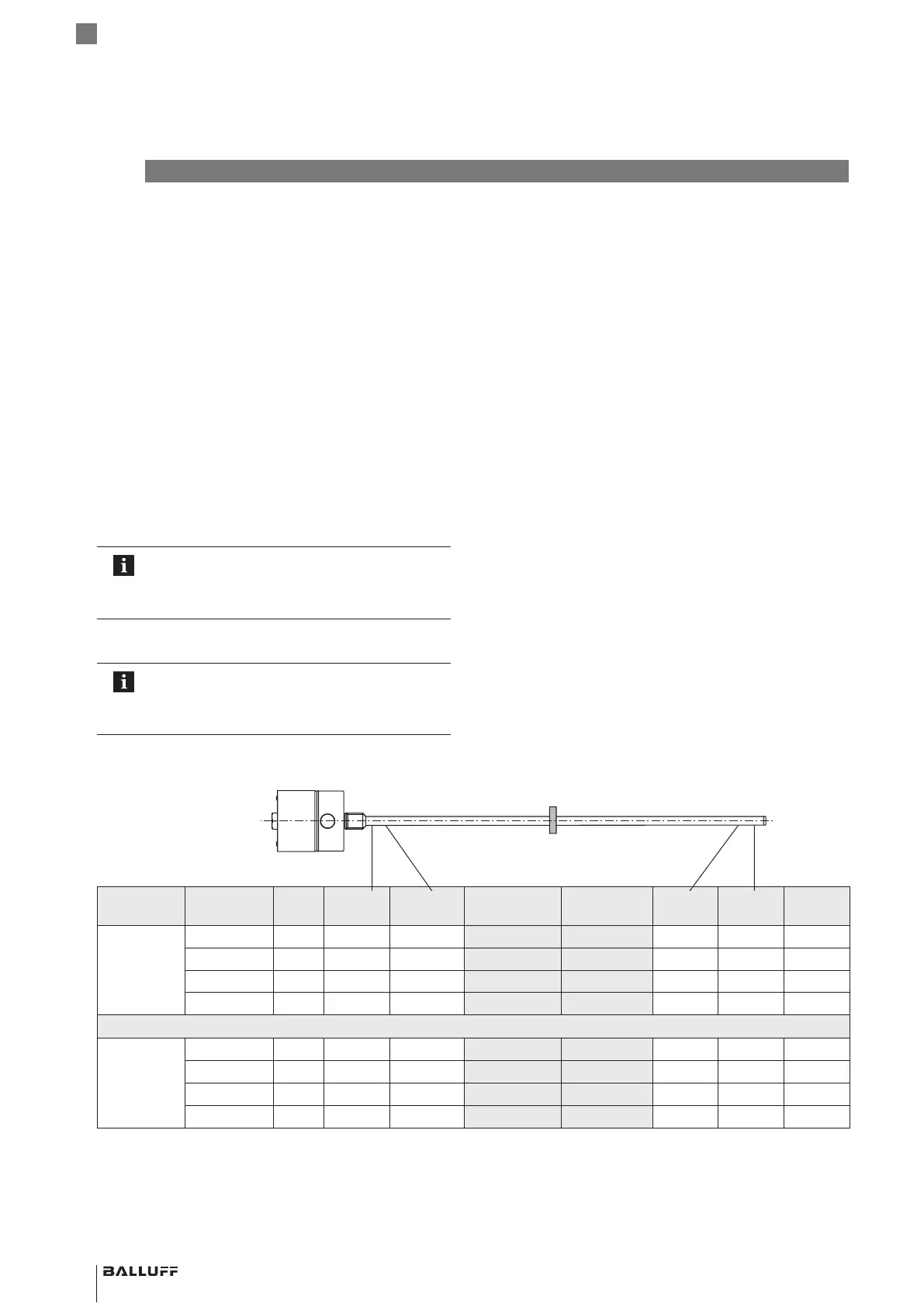

Value table for teach-in and inverting

The following examples refer to BTLs with 0 to

10 V or 4 to 20 mA output.

For all other versions, use the values in the value

table below.

Output

gradient

BTL Unit Min.

value

Nullvalue Indication for

adjustment

Indication

for teach-in

End

value

Max.

value

Error

value

Rising BTL7-A… V −0.5 0 2.0 4.0 +10.0 +10.5 +10.5

BTL7-G… V −10.5 −10.0 2.0 4.0 +10.0 +10.5 +10.5

BTL7-C… mA 0 0 6.0 12.0 20.0 20.4 20.4

BTL7-E… mA 3.6 4.0 6.0 12.0 20.0 20.4 3.6

Falling BTL7-A… V +10.5 +10.0 8.0 6.0 0 −0.5 −0.5

BTL7-G… V +10.5 +10.0 −2.0 −4.0 −10.0 −10.5 −10.5

BTL7-C… mA 20.4 20.0 14.0 8.0 0 0 20.4

BTL7-E… mA 20.4 20.0 14.0 8.0 4.0 3.6 3.6

Tab. 6-1: Value table for teach-in and inverting

Null point End point

BTL7-A/C/E/G5_ _-M_ _ _ _-J-DEXC-TA12

Magnetostrictive Linear Position Sensor – Rod Style

Type of protection “db” and “ta”

Flameproof enclosure

Loading...

Loading...