10 english

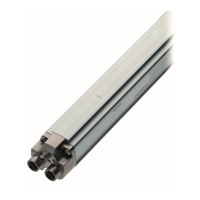

Fig. 4-8:

Magnet

(e.g. BTL-P-1028-15R)

Supporting rod made of non-magnetizable material

Example2, transducer installed with supporting rod

4.4 Electrical connection

Depending on the model, the electrical connection is made

using a cable or a connector (BTL7…-S32, BTL7…-S115)

The connection or pin assignments for the respective

version can be found in Tables 4-2 to 4-4.

Note the information on shielding and cable

routing on page11.

4

Installation and connection (continued)

4.4.1 Connector S32

Pin -A510 -G510 -C500 -C570 -E500 -E570

Fig. 4-9: Pin assignment of S32 (view from

above on transducer), 8-pin M16

circular plug

1 Not used

1)

0…20 mA 20…0 mA 4…20 mA 20…4 mA

2 0 V

3 10…0V 10…–10V 10…0V

3)

4 La (programming input)

5 0…10V –10…10V 0…10V

3)

6 GND

2)

7 10…30V

8 Lb (programming input)

1)

Unassigned leads can be connected to the GND on the controller side but not to the shield.

2)

Reference potential for supply voltage and EMC-GND.

3)

The voltage outputs may exhibit a minimal offset to the harmonized current output.

Tab. 4-2: Connection assignment BTL7…-S32

4.4.2 Connector S115

Pin -A510 -G510 -C500 -C570 -E500 -E570

Fig. 4-10: Pin assignment of S115 (view

from above on transducer), 8-pin

M12 circular plug

1 0 V (pin 3) Not used

1)

2 0 V (pin 5)

3 10…0V 10…–10V Not used

1)

4 La (programming input)

5 0…10V –10…10V 0…20 mA 20…0 mA 4…20 mA 20…4 mA

6 GND

2)

7 10…30V

8 Lb (programming input)

1)

Unassigned leads can be connected to the GND on the controller side but not to the shield.

2)

Reference potential for supply voltage and EMC-GND.

Tab. 4-3: Connection assignment BTL7…-S115

BTL7-A/C/E/G5 __ -M ____ -H/W(8)-S32/S115/___

Micropulse Transducer - Rod Style

Loading...

Loading...