14 english

6.3 Calibration procedure overview

6.3.1 Teach-in

The factory set null point and end point is replaced by a

new null point and end point. The null point and end point

can be set separately, the output gradient changes.

The detailed procedure for teach-in is described

on page16.

Steps

► Move magnet to the new null position.

► Read new null point by activating the programming

inputs.

⇒ The current end point remains the same.

New null point

Before

After

Fig. 6-2: Reading new null point

► Move magnet to the new end position.

► Read new end point by activating the programming

inputs.

⇒ The current null point remains the same.

6

Calibration procedure (continued)

New end point

Before

After

Fig. 6-3: Reading new end point

Only with BTL7-C/E…:

► The gradient of the current output can be inverted by

activating the programming inputs.

⇒ For example, a rising output gradient is changed to

a falling gradient. The voltage outputs are not

inverted.

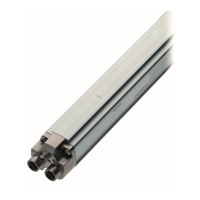

BTL7-A/C/E/G5 __ -M ____ -H/W(8)-S32/S115/___

Micropulse Transducer - Rod Style

Loading...

Loading...