Bandit37

MODEL 75 MAINTENANCE

DRIVE BELT REPLACEMENT

1. Before attempting any type of maintenance,

disengage clutch, wait for the disc/drum to

come to a complete stop, turn off engine,

remove the ignition key, make sure the

ignition key is in your possession, install the

disc/drum lock pin, and disconnect the battery.

2. If machine has been running, allow time for the

hydraulic oil to cool down before continuing.

3. Remove beltshield.

4. Remove the hydraulic suction hose from the

hydraulic pump, the hose can be capped with

a 3/4” NPT pipe cap. If the hose is not capped,

keep the end of the hose higher than the

hydraulic tank.

5. Remove the hydraulic pressure hose from the

hydraulic pump, the hose can be capped with a

#10 male JIC cap.

6. Remove the bolts that hold the torque arm to the

hydraulic pump.

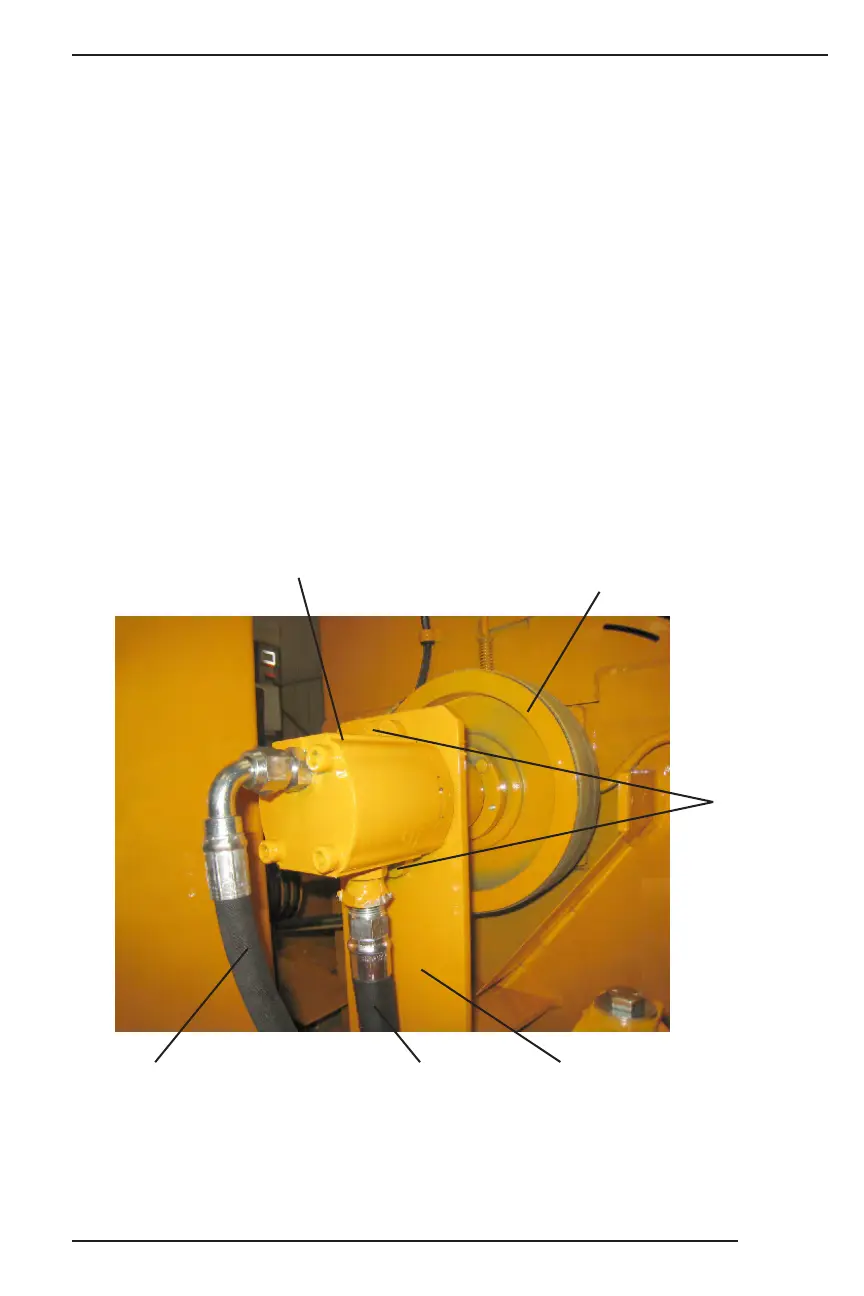

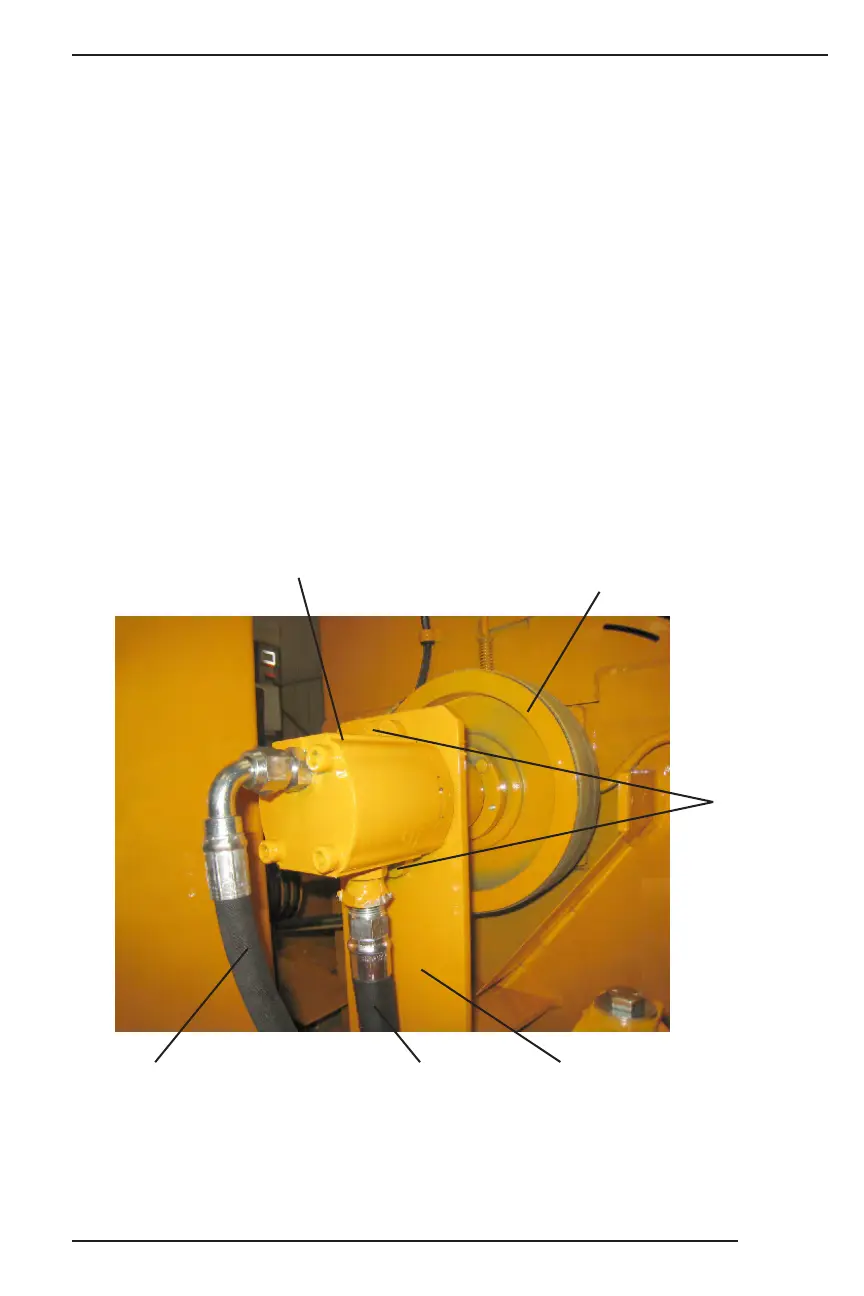

Hydraulic

Pump

Chipper

Sheave

Hydraulic

Suction

Hose

Hydraulic

Pressure

Hose

Torque

Arm

Torque Arm

Bolts

7. Remove the old drive belts and place the new drive

belts on. The engine may have to be adjusted in

order to do this.

8. Adjust the belts to the correct tension, see pages

38 - 39.

9. Bolt the torque arm to the hydraulic pump.

10. Reassemble both hydraulic hoses to the hydraulic

pump.

11. Reinstall beltshield.

12. Check the hydraulic uid level and ll to 7/8 full,

if needed.

13. After running the machine for a few minutes, the

hydraulic oil level will need to be checked again

and lled to 7/8 full, if needed.

14. Check the hydraulic hoses to make sure they are

tight and not leaking.

15. Remember new belts stretch and will need to

be checked often, tighten if needed, see pages

38 - 39.

16. Resume normal operation.

Loading...

Loading...