501/21

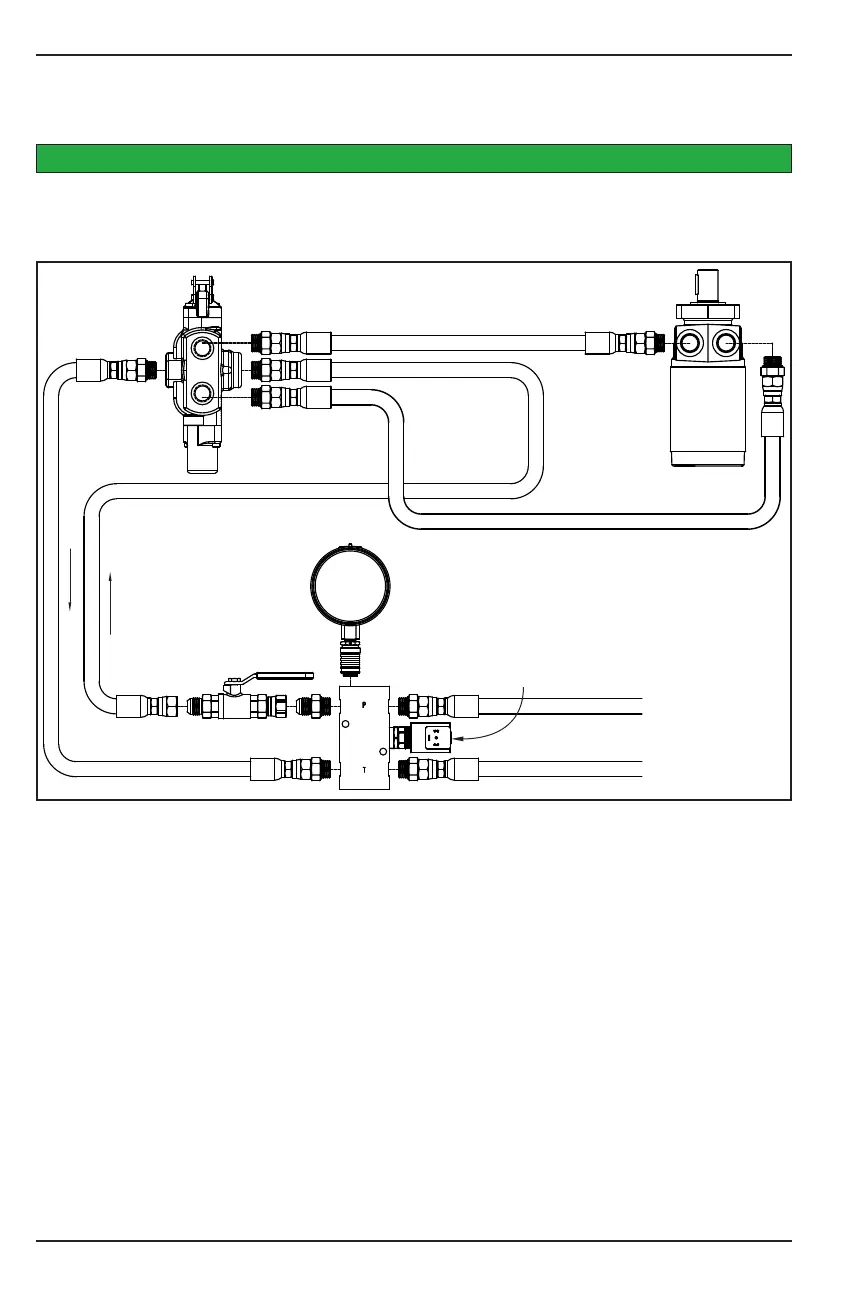

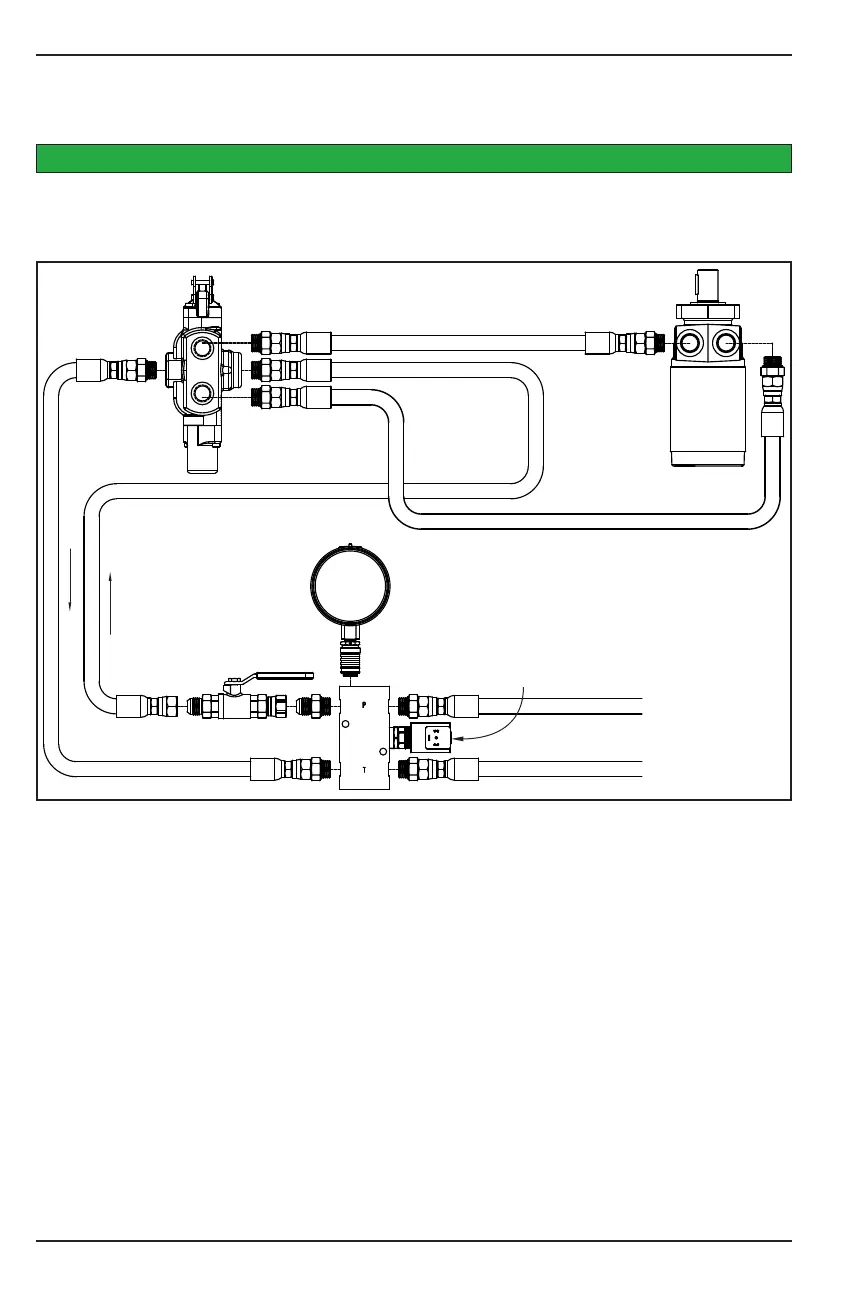

MODEL 75 HYDRAULICS

With the engine shut down, make sure the hydraulic oil is clean and the tank is 7/8 full. Start the engine

to allow the hydraulic oil to warm up. Before checking or adjusting the hydraulic pressure settings, make

sure the engine is shut o and the ignition key is in your possession. Ensure the pressure gauge is installed

correctly to check the relief valve pressure.

1. Put the control bar in the o position.

2. Install pressure gauge on the test nipple that is

on the main relief.

3. Start engine with the control bar in the off

position.

4. Adjust engine to full throttle.

5. Close the ball valve.

6. Pressure gauge should read maximum specied

PSI (bar).

ONLY CLOSE BALL VALVE FOR 4-5 SECONDS

TO SET PRESSURE OR YOU MAY DAMAGE

HYDRAULICS.

MAINTAIN FEEDWHEEL HYDRAULIC PRESSURE AT SPECIFIED PSI (bar).

HYDRAULIC PRESSURE ADJUSTMENT

PRESSURE CHECK KIT

7. Locate the relief on the feedwheel control valve,

loosen jam nut, use an allen wrench to readjust

relief pressure setting if needed, and then

retighten jam nut.

8. Remove the pressure gauge and place the

rubber cap back on the test nipple.

9. Check for hydraulic leaks.

10. Relief valve pressure should be checked and

readjusted as needed once a month for best

performance.

SAFETY INSTRUCTIONS

OUT

IN

From Pump

Gauge

Ball Valve

Feedwheel

Control Valve

Hydraulic

Feedwheel Motor

Dump

Cartridge

To Tank

Loading...

Loading...