Bandit51

MODEL 75 HYDRAULICS

HYDRAULIC MOTOR CHECK OUT

CORRECTING HYDRAULIC PROBLEMS

MACHINES WITH LIVE HYDRAULICS

To check out the hydraulic motor, the following will be needed: a pressure gauge capable of reading 3000

psi (207 bar), a Tee tting to install to the control valve, a plug tting to install in the control or relief valve, and

a clean 5 gallon (19L) pail.

1.

The following instructions are for machines

with Live Hydraulics, for machines without Live

Hydraulics contact your local dealer or Bandit

Industries.

In order to check out a hydraulic motor, it is

necessary to mechanically stop the motor from

turning while under load. The hydraulic pump

needs to be driven without turning the chipper

disc/drum (Live Hydraulics). Feed a reasonably

large size log into the machine until it contacts

the stationary disc/drum. This should stall the

hydraulic motor(s). It may also be necessary

to apply down pressure by operating the yoke

control valve (if equipped).

With the feedwheel(s) mechanically locked as

described, turn the engine o and keep the

key in your possession. If the hydraulic motor

does not have a case drain, unhook the hose

going from the hydraulic motor back to the

control valve at the valve, some machines will

be equipped with a ow divider between the

hydraulic motor and the control valve. If the

hydraulic motor has a case drain, unhook the

case drain hose that goes to the relief valve at

the valve and put the hose into the hydraulic

tank.

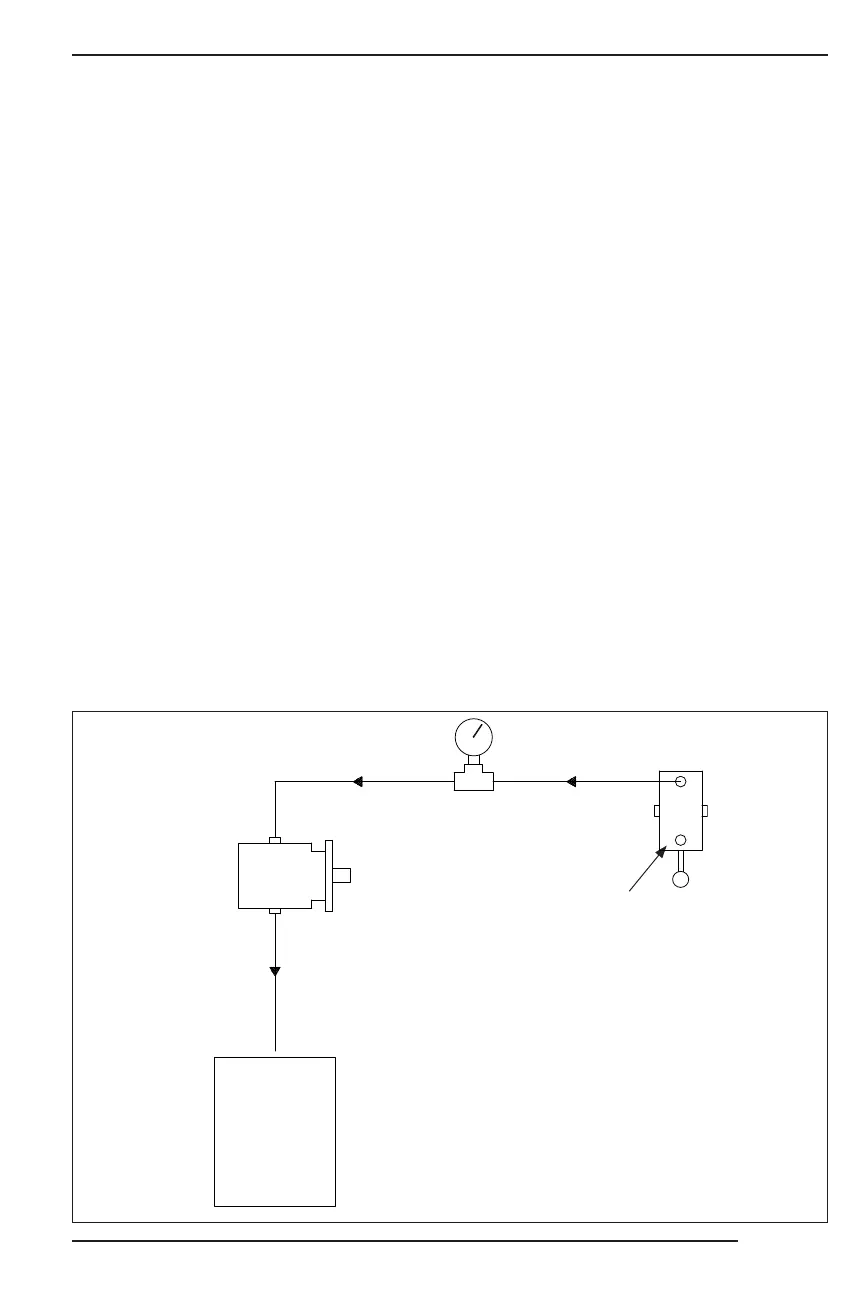

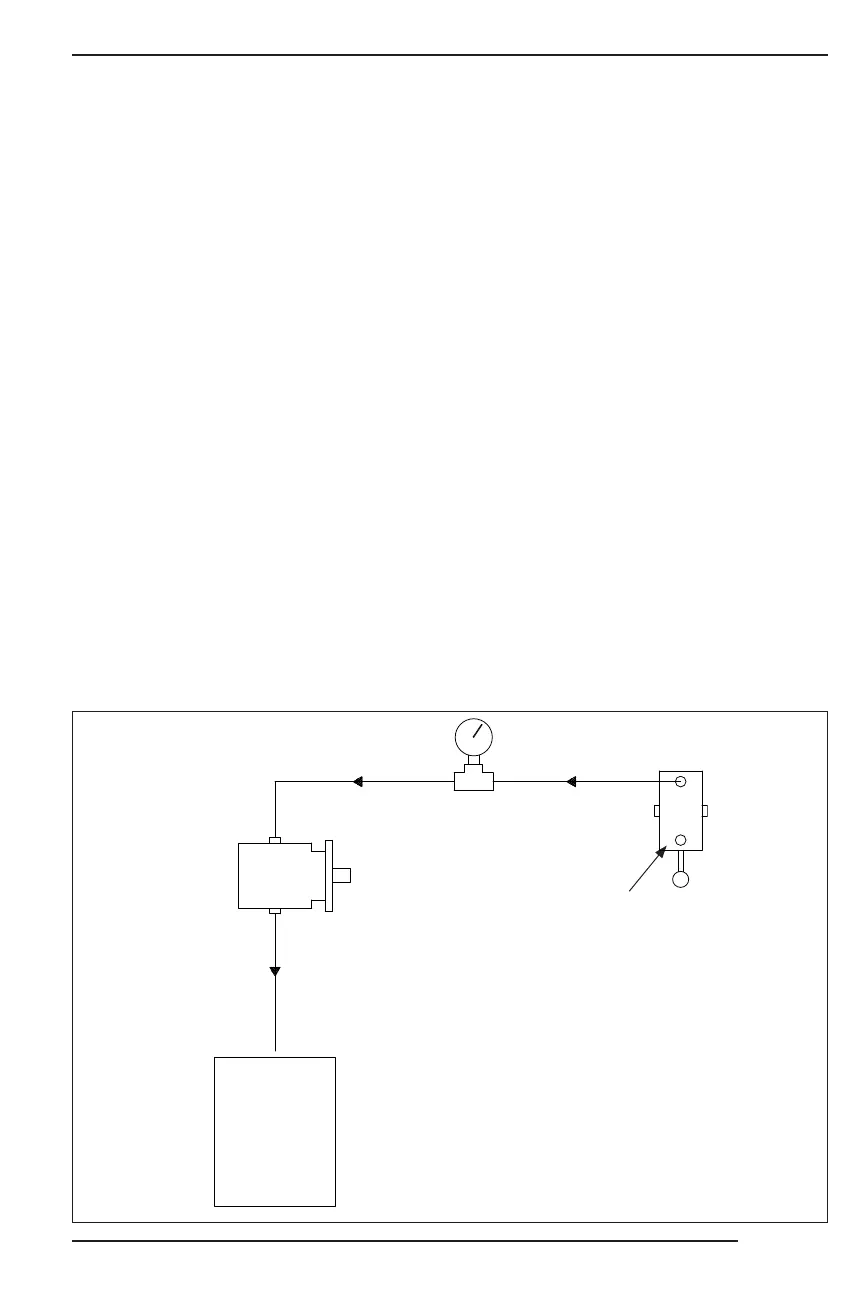

Hydraulic

Motor

Flow

Direction

Tee

Fitting

Flow

Direction

Control

Valve

Gauge

Clean

5 Gallon

Pail

Plugged

Port

0

0

0

0

0

0

0

0

0

0

0

4.

Place the end of the hose in a clean 5 gallon

(19L) pail.

5.

Plug the open port of the control valve or main

relief valve.

6.

Unhook the other hose in the control valve and

install a Tee tting into the control valve and

attach the hose to the Tee tting.

7.

Install a pressure gauge in the other port in the

Tee tting to monitor hydraulic pressure.

8.

Put the infeed control valve in the center

position and start the engine.

9. Increase the engine speed slowly to full rpm.

10.

Operate the infeed control valve to feed the log

into the stationary disc/drum. If the feedwheel(s)

try to turn, apply down pressure by using the

yoke control valve (if equipped).

11.

Providing the pump and the relief are functioning

properly, the pressure gauge should read the

speci ed main relief setting.

12.

Observe the amount of hydraulic uid coming

from the hose into the pail. If the amount of

leakage in the pail is 1 gpm. (3.8 Lpm) or less

the motor is good. If the amount of leakage in

the pail is over

1 gpm (3.8 Lpm) the motor needs to be

replaced.

Loading...

Loading...