e

Mark

MAINTENANCE

We recommend that the final pressure gauge is checked

from time to time. For this purpose we have developed a

special test pressure gauge with an adaptor which immedi

ately recognizes any deviations in readings (see High Pressure

Accessories Catalogue 8550/..).

Slight deviations during operation are normal and can be ig

nored. Excessive inaccuracy will require the pressure gauge

to be replaced.

4.4.8. VALVES

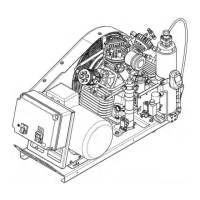

DESCRIPTION

The valve heads of the individual stages form the top part of

the cylinders. The intake and pressure valves are fitted inside

the valve heads. Note that the valves are operated by the

flow of the air.

On the suction stroke, the intake valves open and the air

flows into the cylinders. At the start of the compression

stroke the intake valve closes and the air opens the pressure

valve, Fig. 34.

Intake and pressure valve of the 1st stage is a plate valve

(Fig. 35).

INITIAL OPERATIONAL CHECK

After maintenance work on the valves, valves should be

checked. Note that the intake line to the valve heads should

be warm and outlet piping should be hot. Valves are then op

erating properly.

Fig. 34 Valve operation

Intake Pressure

Fi

Intake sidePressure side

Top view

from intake fil

ter

to 2nd stage

N4860−F98

GENERAL INSTRUCTIONS FOR CHANGING THE VALVES

- Always replace valves as a complete set.

- Observe the correct sequence when fitting together

again.

- Check individual components for excessive wear. If the

valve seat and valve disks are dented, replace the valves.

- Valve head screws must be tightened with a torque

wrench (see tightening torque values chapter 7.).

- Check the valve space in the valve heads for dirt and

clean, if necessary.

- 30 minutes after restarting the compressor stop unit,

let it cool down to ambient temperature and retighten

valve studs and cap nuts. Otherwise valves could work

loose due to setting of the gaskets.

- Use only satisfactory gaskets and O-rings on reassembly.

- After finishing all maintenance work on the valves, turn

the compressor manually using the flywheel and check

whether all items have been correctly installed.

Loading...

Loading...