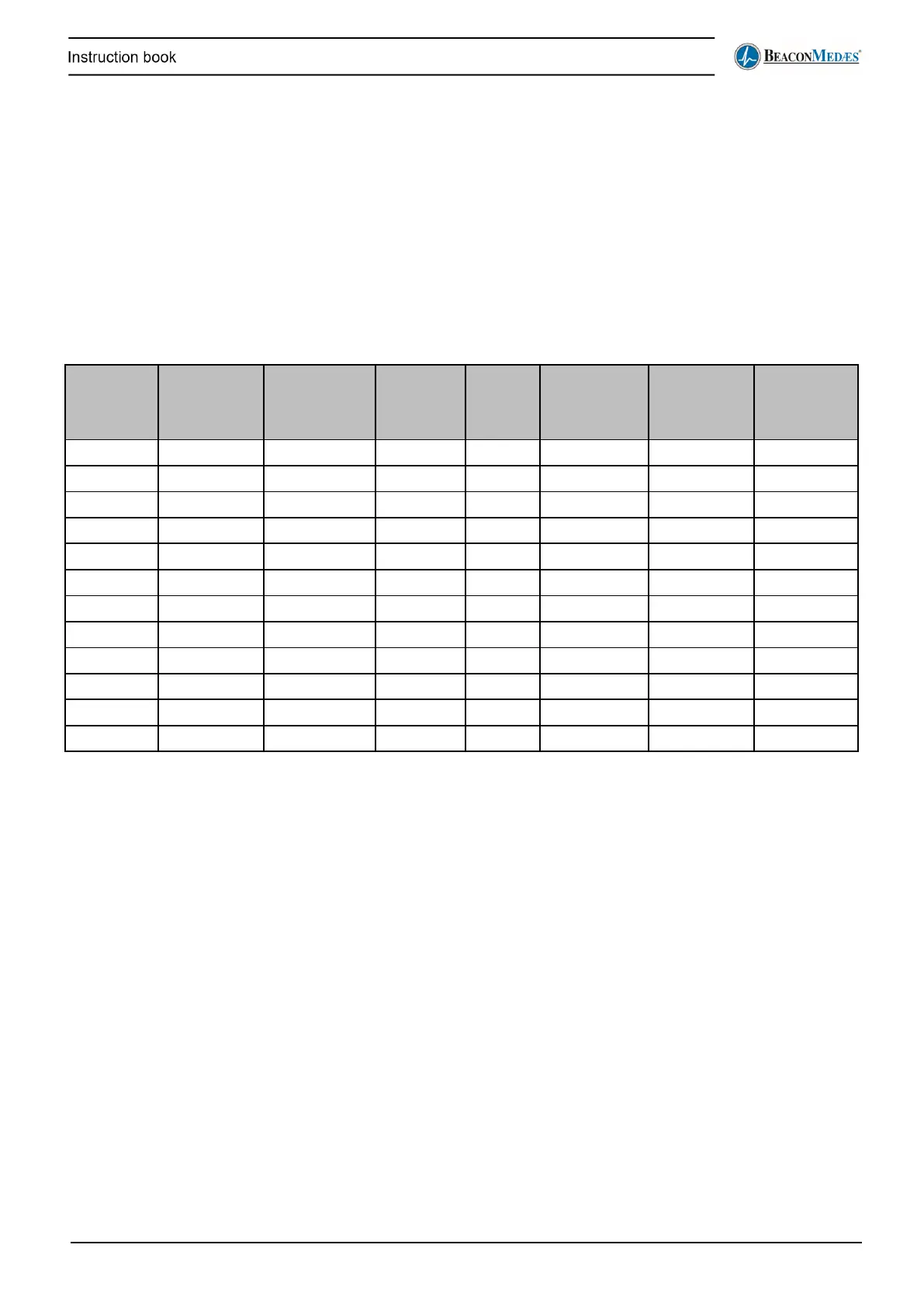

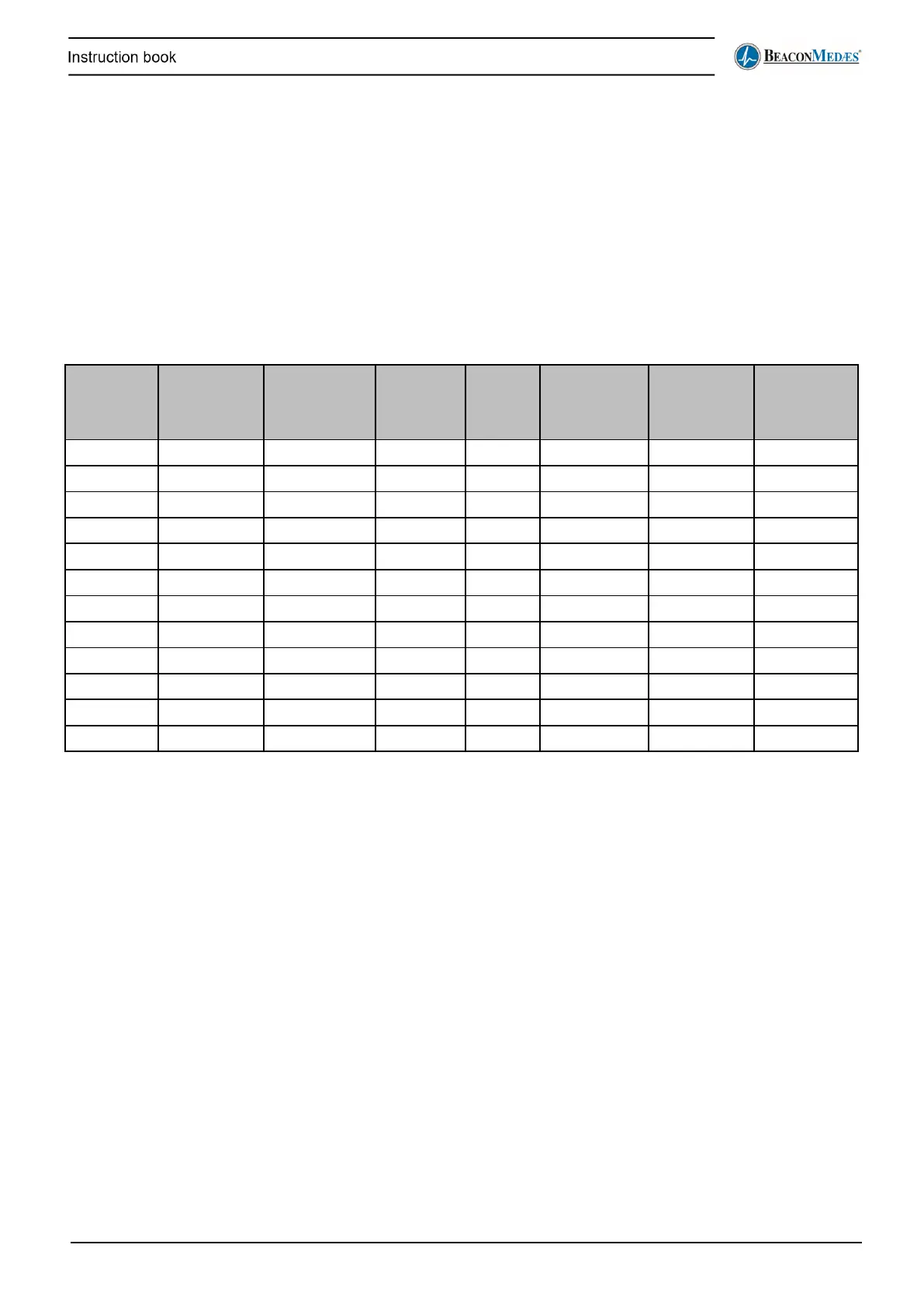

11.2 Pressure equipment directives

Components are subject to Pressure Equipment Directive 2014/68/EU.

Parts of article 4.3 of 2014/68/EU are subject to Sound Engineering Practice (SEP).

Parts of category I according to 2014/68/EU are integrated into the machine and fall under the

exclusion of article I, section 2-(f)-(i).

Below table contain the necessary information for the inspection of all pressure equipment of

category I according Pressure Equipment Directive 2014/68/EU.

DRYER TYPE

DESIGN

PRESSURE

(BARG)

DESIGN

TEMPERATURE

(°C)

PED

CATEGORY

MODULE

EXTRUSION

WALL THICKNESS

(mm)

EXTRUSION

INTERNAL

DIAMETER (mm)

VOLUME (Litres)

PD025 16 5 to 50°C CAT I A 3 86 11

PD035 16 5 to 50°C CAT II D1 3 86 15.8

PD0046 13 5 to 50°C CAT II D1 7 149 22.2

PD0056 13 5 to 50°C CAT II D1 7 149 25.2

PD0075 13 5 to 50°C CAT II D1 7 149 31.4

PD0090 13 5 to 50°C CAT II D1 7 149 35.9

PD0110 13 5 to 50°C CAT II D1 7 149 44.6

PD0150 13 5 to 50°C CAT II D1 7 149 56.8

PD0180 13 5 to 50°C CAT II D1 7 149 66

PD0220 13 5 to 50°C CAT III B1+D 7 149 88.6

PD0300 13 5 to 50°C CAT III B1+D 7 149 113

PD0360 13 5 to 50°C CAT III B1+D 7 149 131.5

Recommendation of the manufacturer for the re-inspection time

Following actions are to be executed by authorized service personnel, unless stated differently in

the applicable legislation. The stated time interval has as reference the day of start-up of the unit.

• Every 6 months: visual check of the vessel material on the outside (exposed) for traces of

strong corrosion. Consult the service department of your supplier if necessary.

• Every 5 years: when replacing the desiccant, following inspections are to be carried out:

• Inspection of outside and inside of the material for excessive and local corrosion,

• Inspection of outside and inside of the material for fissures, leaks, damage. Consult the

service department of your supplier if necessary.

• Every 10 years: hydrostatic test according to the Pressure Equipment Directive 2014/68/EU.

Consult the service department of your supplier if necessary.

Loading...

Loading...