54

86105 BA-en/00

English ⋅ Nautilus

®

CC plus

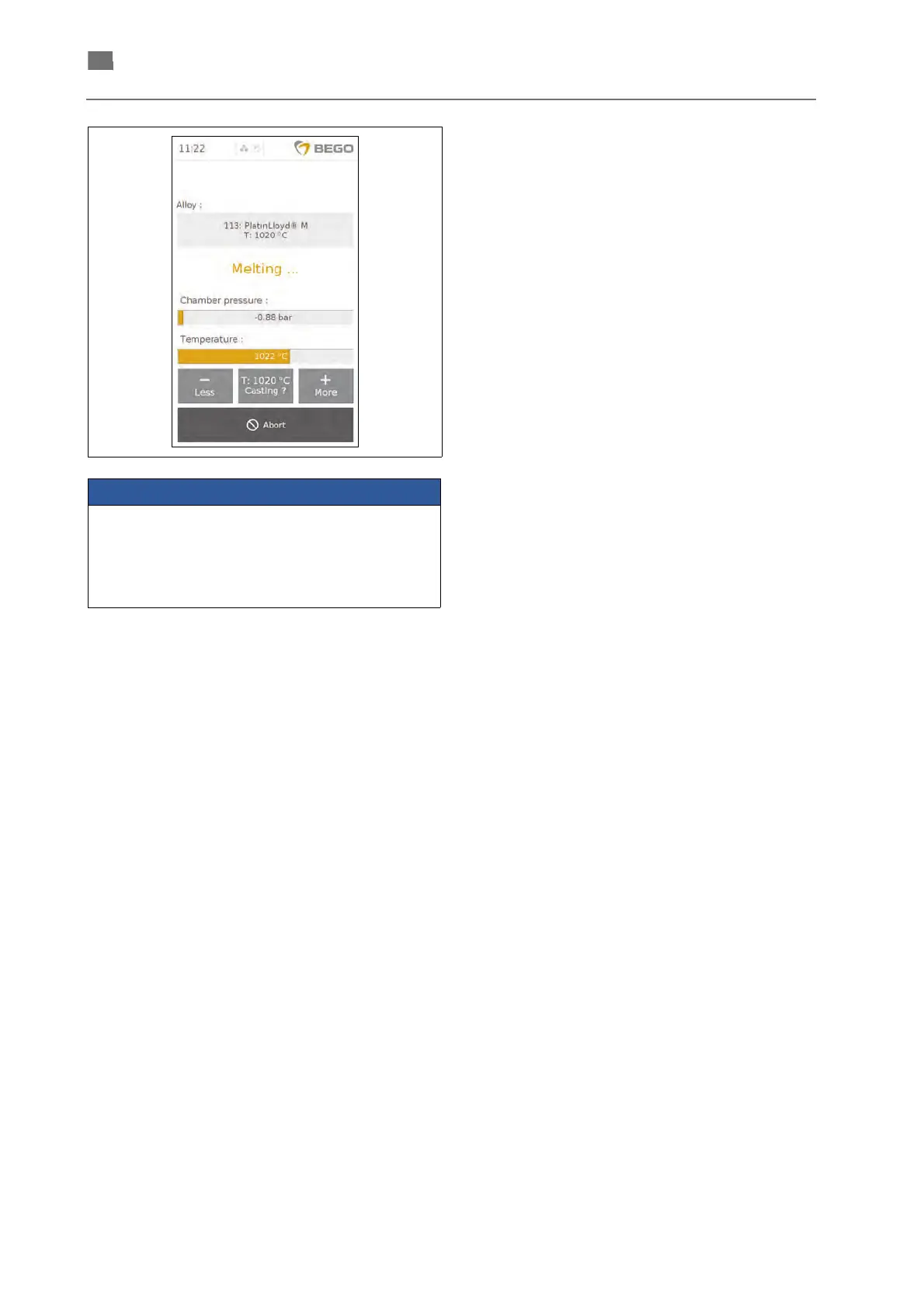

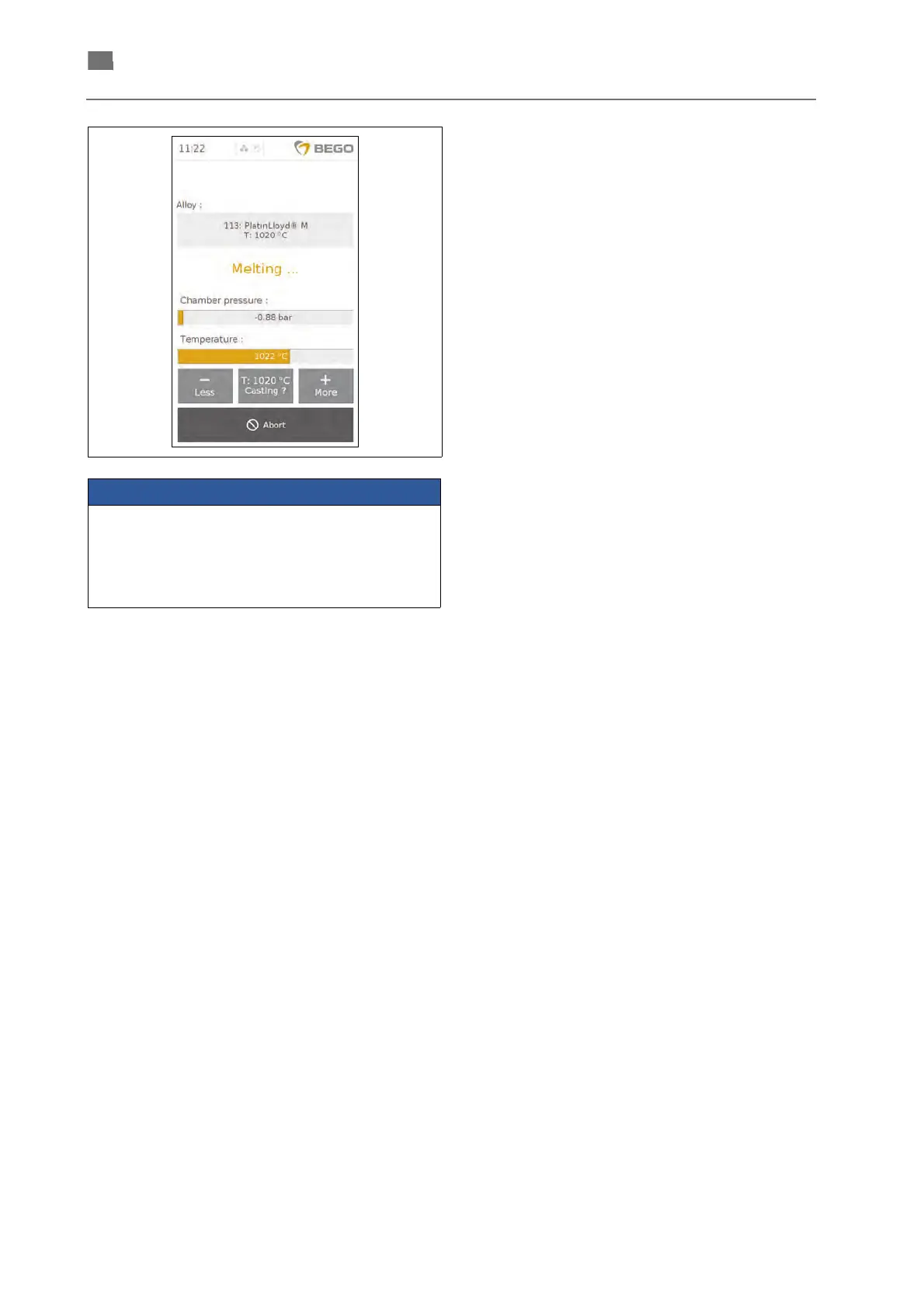

10. Apply the program-specific casting tempera-

ture.

11. Alternatively, the casting temperature may be

adjusted individually. Adjust the casting tem-

perature by pressing the "+" and/or "-" buttons

once the actual and the casting temperature

are above 700°C.

• If the ideal casting temperature is higher

than the temperature that is being dis-

played, it must be increased. The tempera-

ture is increased by 10°C every time the "+"

button is pressed.

• If the ideal casting temperature is lower than

the one that is being displayed, it needs to

be reduced by pressing the "-" button. With

unknown alloys, the process is started at a

lower temperature

12. When the melt appears to be ready for casting,

press the "Casting" button to trigger the pro-

cess. Observe the following notes.

EMF (non-precious) alloys without crucible

inserts: Trigger the casting process when the cast-

ing temperature is reached and the alloys melt

appears ready for casting after visual evalua-

tion.

Pd-based alloys without crucible insert : When

the casting temperature is reached, wait for 10

seconds before triggering the casting process.

Precious-metal alloys with crucible insert:

When the casting temperature is reached, it

must be maintained for several seconds before

the casting process is triggered (see table on

page 35). This holding time is absolutely nec-

essary to optimize the flow behaviour of the

alloy! Trigger the casting process when the

holding time has elapsed and the actual tem-

perature has reached the casting temperature.

The melt is moved by the magnetic field, not by

heat. The moving melt is therefore not a boiling

melt. The automatic starting and stopping of the

generator ("clocking") does not cause the casting

temperature to be exceeded.

Loading...

Loading...