25Bend-Tech Dragon A150

Troubleshooting Guide

Toolhead

03

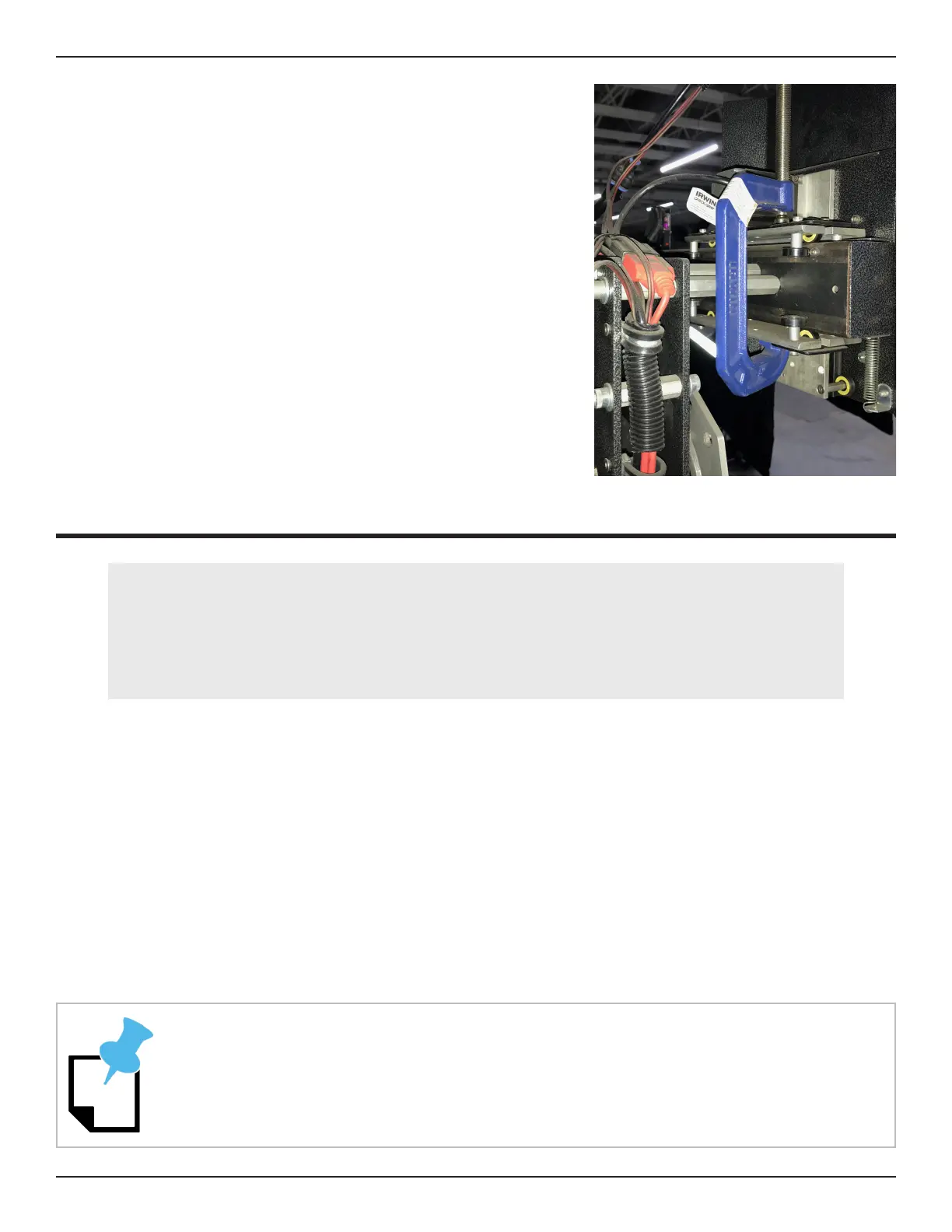

6. Using a larger C-clamp, apply the clamp to the

Toolhead trolley so it puts slight pressure on both

the upper and lower halves of the trolley assembly.

Tighten the mount plate screws securely. Using the

same process, apply a C-clamp to the other end of

the trolley assembly. Adjust the C-clamps so there is

enough pressure on the trolley to eliminate any play

but still allow it to ride smoothly along the rail. When

this is achieved, tighten the Toolhead mount plate

screws, then tighten another quarter turn.

7. Reassemble the Toolhead by reversing the order of

disassembly.

Toolhead Rail

Leveling The Toolhead Rail

For most accurate cutting the Operator should ensure the Toolhead rail is level. Leveling the

Toolhead rail and the Chuck allows the machine to perform the most accurate operations

possible.

1. Place a level on the Toolhead rail.

2. If the Toolhead rail is not level, adjust the machine’s leveling feet to bring the Toolhead rail

to level.

3. Once the Toolhead rail is level, secure the leveling feet. With the leveling feet secure, re-

check to ensure the Toolhead rail is still level.

Tools Needed

• Torpedo level

• Leveling foot adjustment wrench

If the Dragon A150 is not equipped with leveling feet it will be necessary to shim the

legs of the machine to bring it to level.

Loading...

Loading...