3

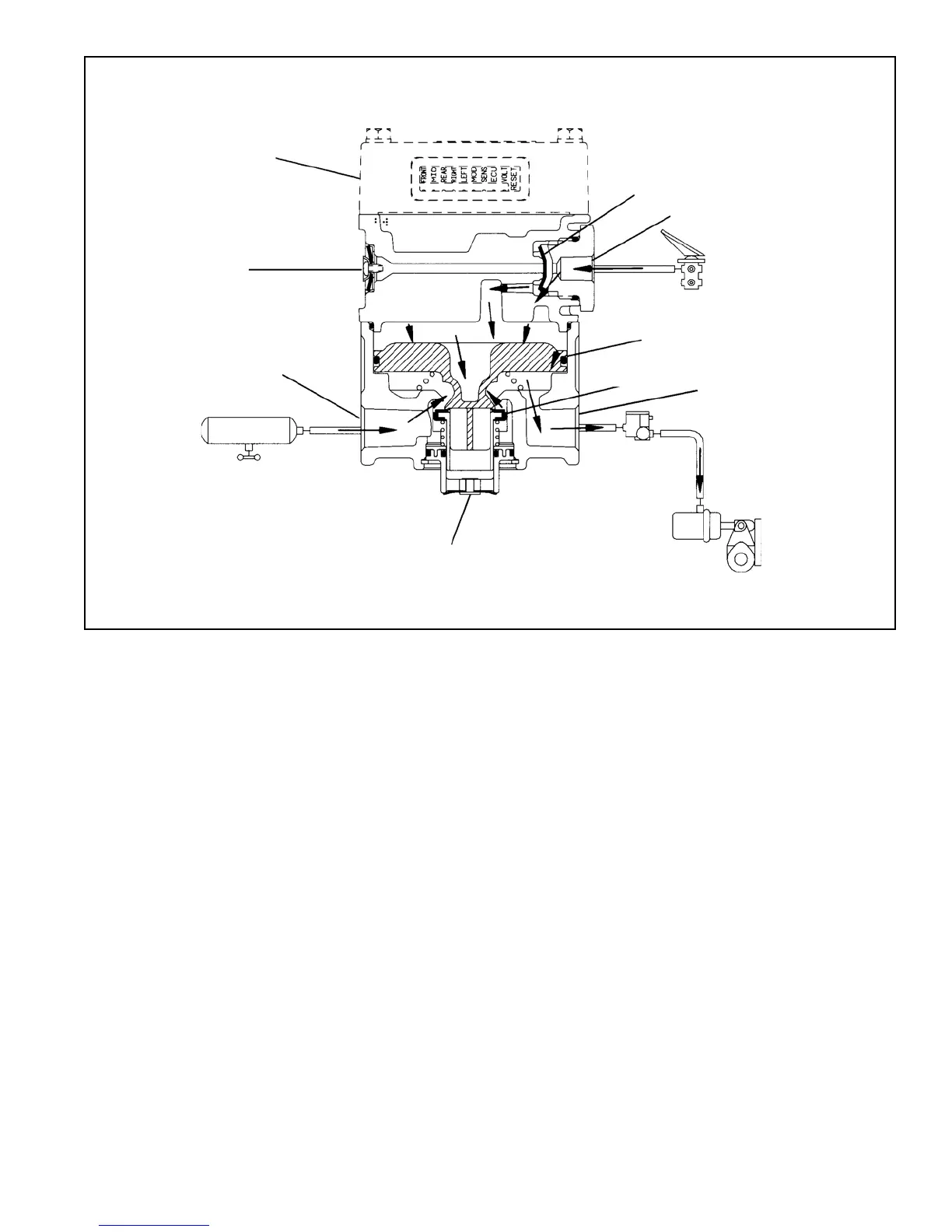

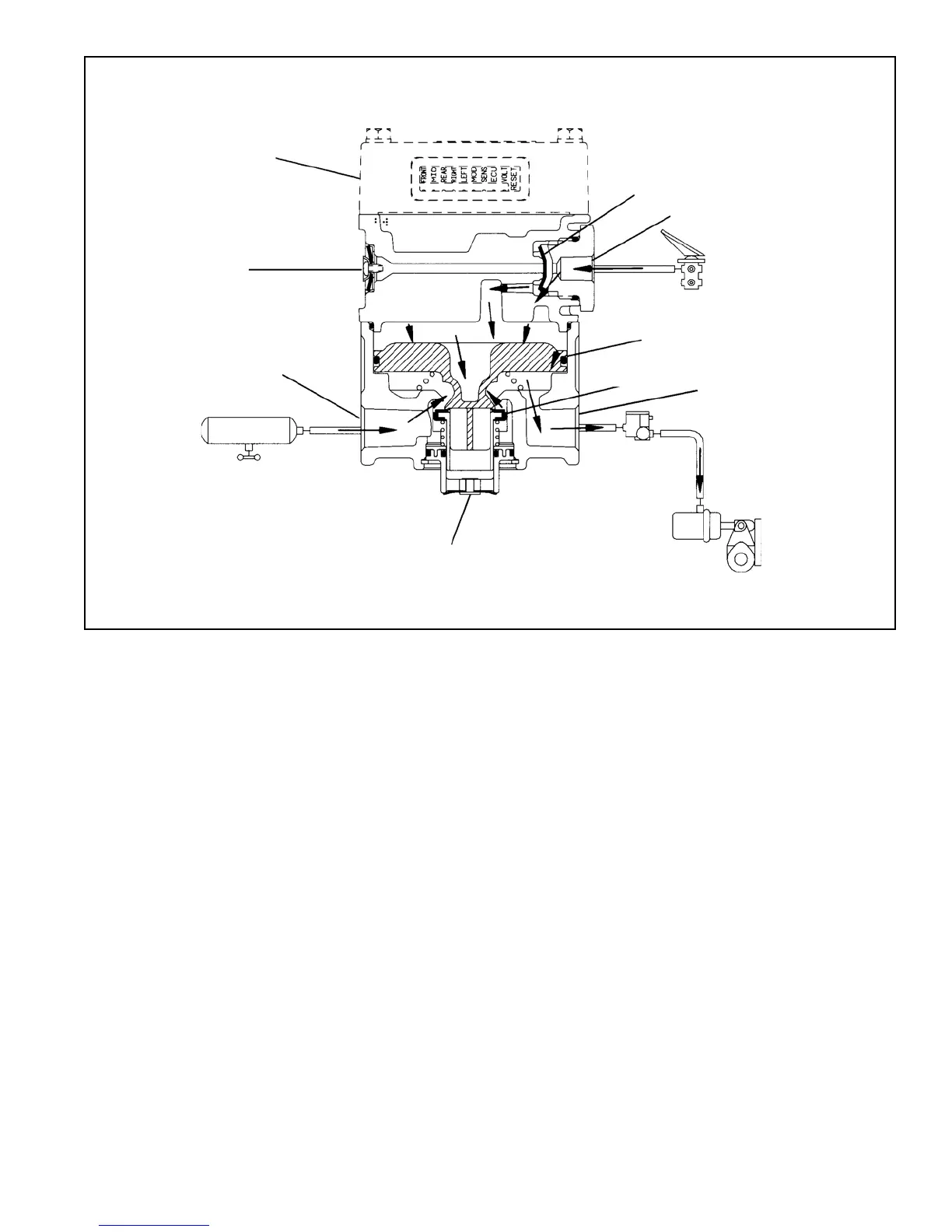

FIGURE 3 - AR-1

™

VALVE BRAKE APPLICATION

RESERVOIR

BRAKE

ACTUATOR

PREVENTIVE MAINTENANCE

Important: Review the warranty policy before performing

any intrusive maintenance procedures. An extended warranty

may be voided if intrusive maintenance is performed during

this period.

Because no two vehicles operate under identical conditions,

maintenance intervals will vary. Experience is a valuable guide

in determining the best maintenance interval for a vehicle.

GENERAL

Perform the tests and inspections presented at the

prescribed intervals. If the AR-1

™

valve fails to function as

described, or leakage is excessive, it should be repaired or

replaced with a new or genuine Bendix remanufactured

unit, available at any authorized parts outlet.

EVERY 3 MONTHS, 25,000 MILES OR 900

OPERATING HOURS

1. Remove any accumulated contaminates and visually

inspect the exterior for excessive corrosion and physical

damage.

2. Inspect all air lines connected to the AR-1

™

valve for

signs of wear or physical damage. Replace as necessary.

3. Test air line fittings for excessive leakage and tighten or

replace as necessary.

4. Perform the Leakage Test described in this manual.

EVERY YEAR, 100,000 MILES, OR 3,600

OPERATING HOURS

1. Perform the Operation and Leakage Tests described in

this manual.

OPERATION & LEAKAGE TESTS

OPERATING TEST

1. Apply and release the brakes several times and check

for prompt application and release at each wheel. If

prompt reaction is noted at some, but not all wheels,

test the AntiLock modulator between the AR-1

™

valve

and the brake actuator for proper operation. If a “sluggish”

response is noted at all wheels, inspect for a kinked or

obstructed air line leading to or from the AR-1

™

valve.

2. If a complete release of the brakes is noted at some, but

not all wheels, test the antilock modulator between the

AR-1

™

valve and the brake actuator for proper operation.

If an incomplete release is noted at all wheels, inspect

for a kinked or obstructed air line leading to or from the

AR-1

™

valve.

SUPPLY PORT

EXHAUST

ANTILOCK

CONTROLLER

QUICK EXHAUST DIA.

SERVICE PORT

RELAY PISTON

DELIVERY PORT

INLET/EXH.

VALVE

ANTILOCK

MODULATOR

EXHAUST

Loading...

Loading...