5

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix

®

replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored to

their proper operating condition.

VALVE REMOVAL

1. Park the vehicle on a level surface and block the wheels

and/or hold the vehicle by means other than the air

brakes.

2. Drain the air pressure from all vehicle reservoirs.

3. Identify, mark or label all air lines and wiring cables and

their respective connections on the valve or antilock

controller to facilitate ease of installation.

4. Disconnect all air lines and wiring.

5. Remove the valve and controller assembly from the

vehicle.

VALVE INSTALLATION

1. Install all air line fittings and plugs making certain thread

sealing material does not enter the valve.

2. Install the assembled valve on the vehicle.

3. Reconnect all air lines and wiring cables to the valve and

controller assembly using the identification made during

VALVE REMOVAL step 3.

4. After installing the valve and controller assembly, test all

air fittings for excessive leakage and tighten as needed.

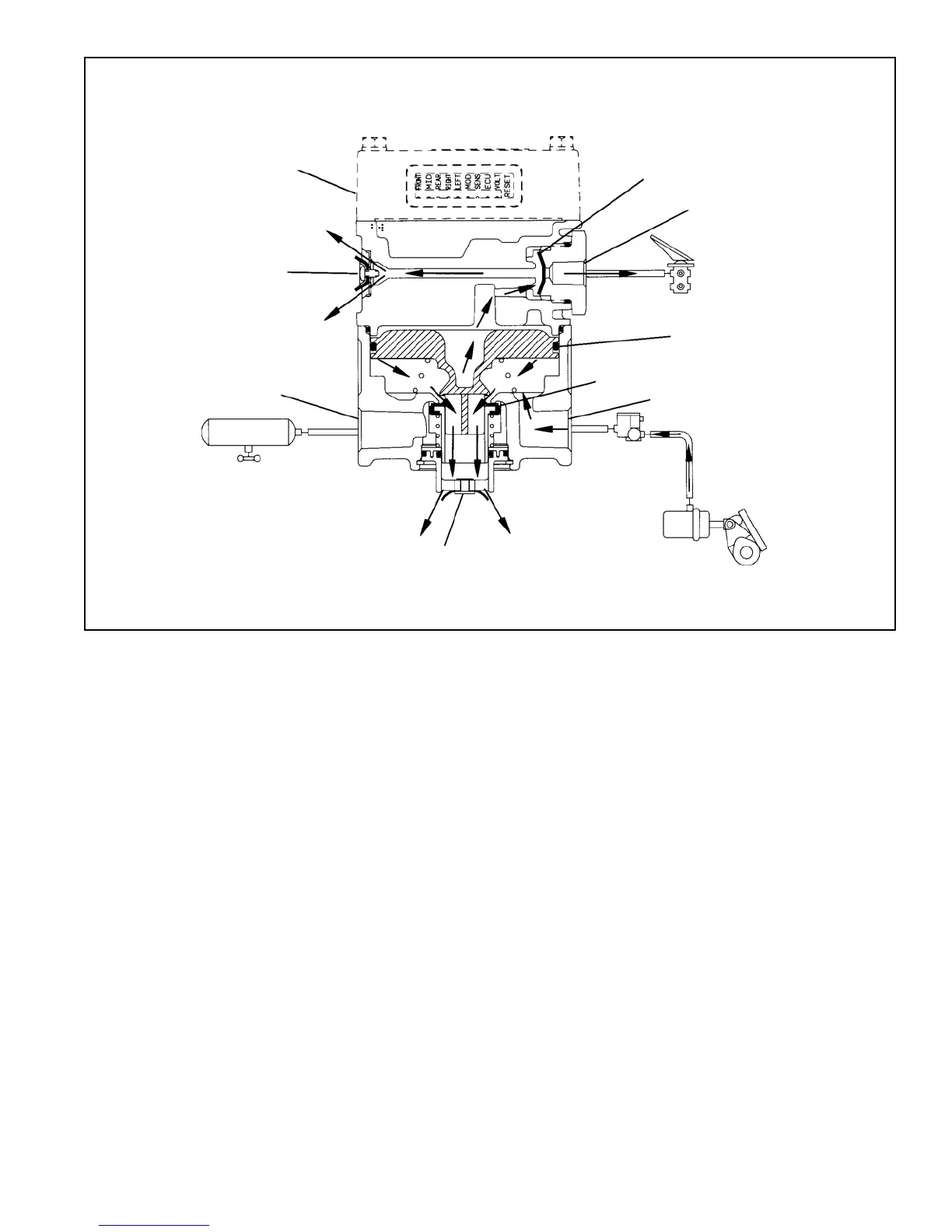

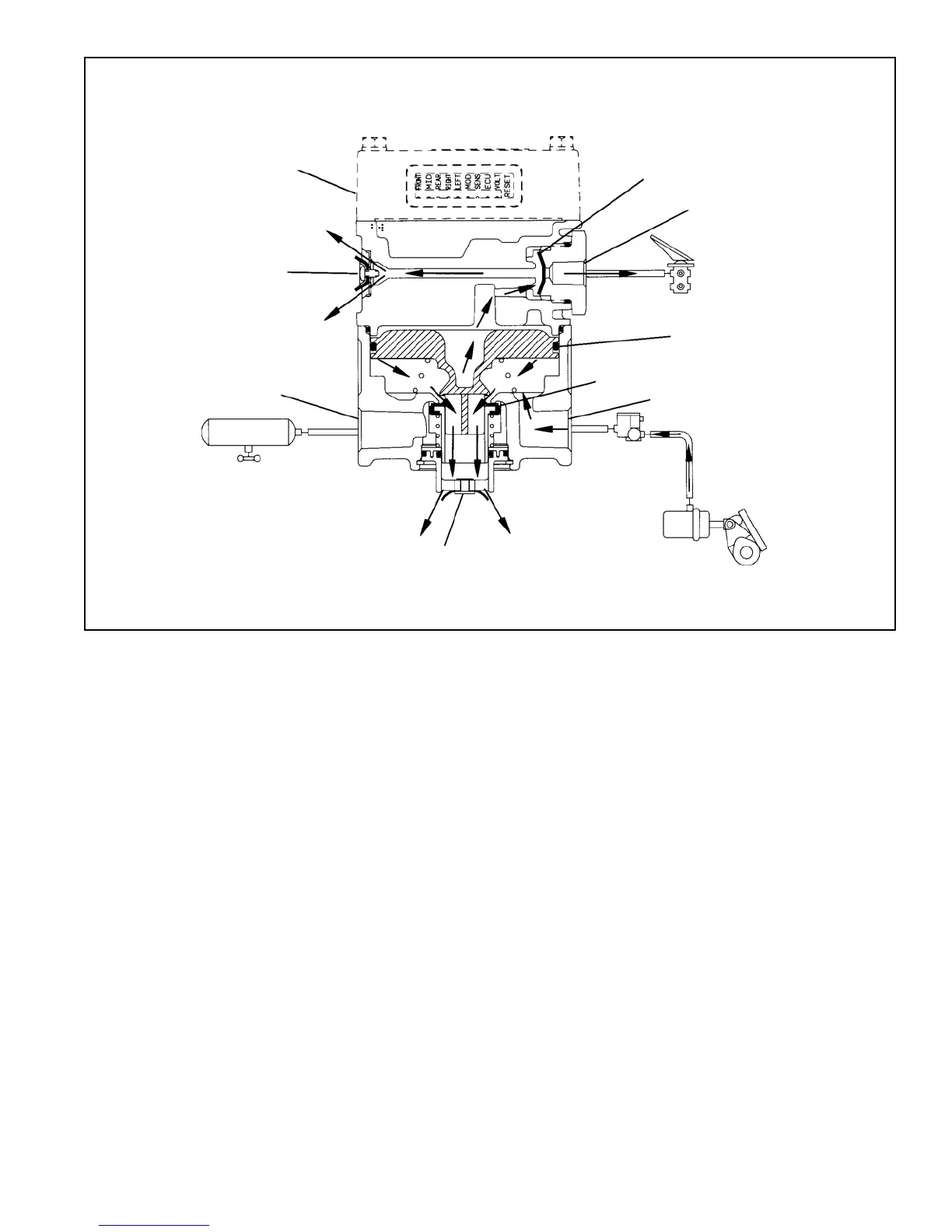

FIGURE 5 - AR-1

™

VALVE EXHAUST - BRAKE RELEASE

RESERVOIR

BRAKE

ACTUATOR

SUPPLY PORT

EXHAUST

ANTILOCK

CONTROLLER

QUICK EXHAUST DIA.

SERVICE PORT

RELAY PISTON

DELIVERY PORT

INLET/EXH. VALVE

ANTILOCK

MODULATOR

EXHAUST

Loading...

Loading...