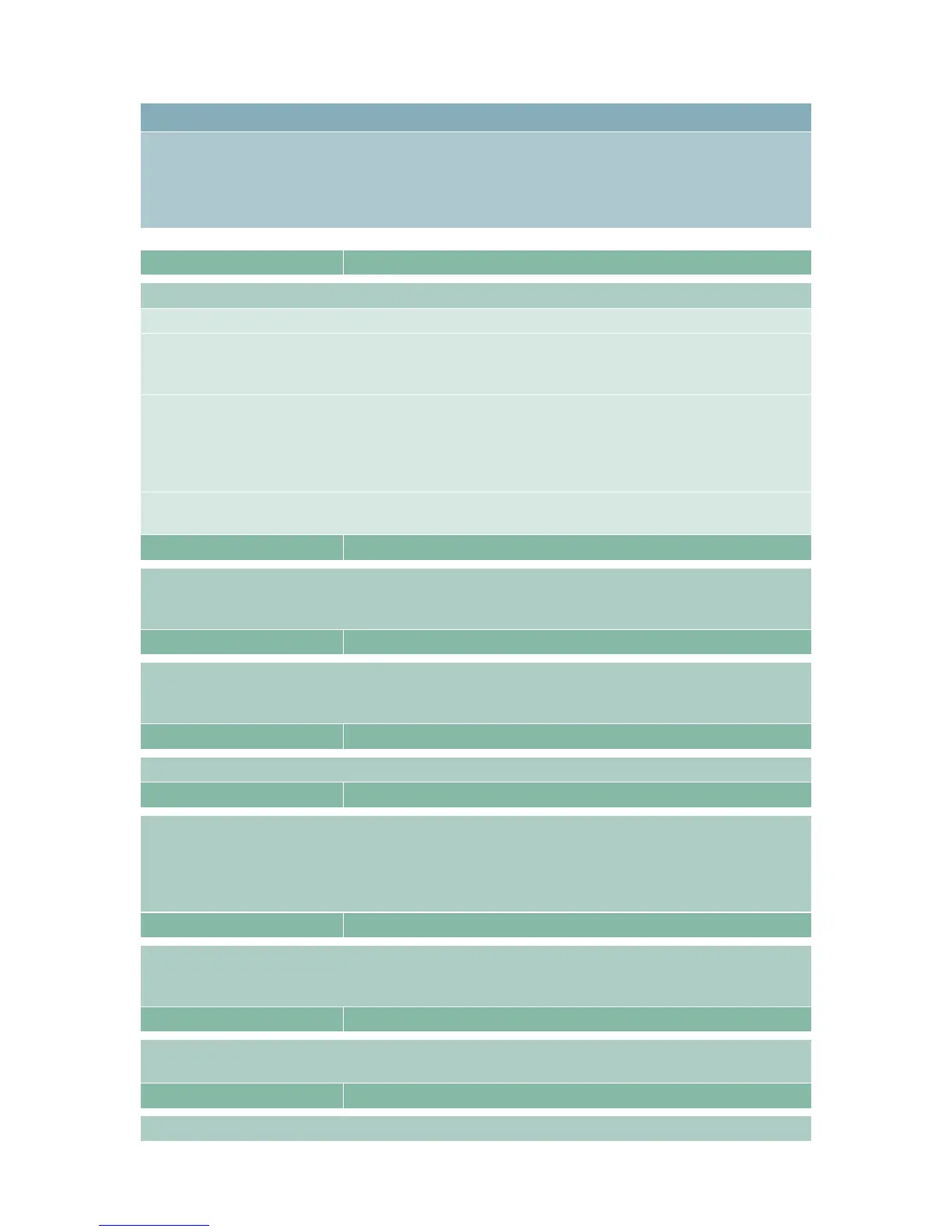

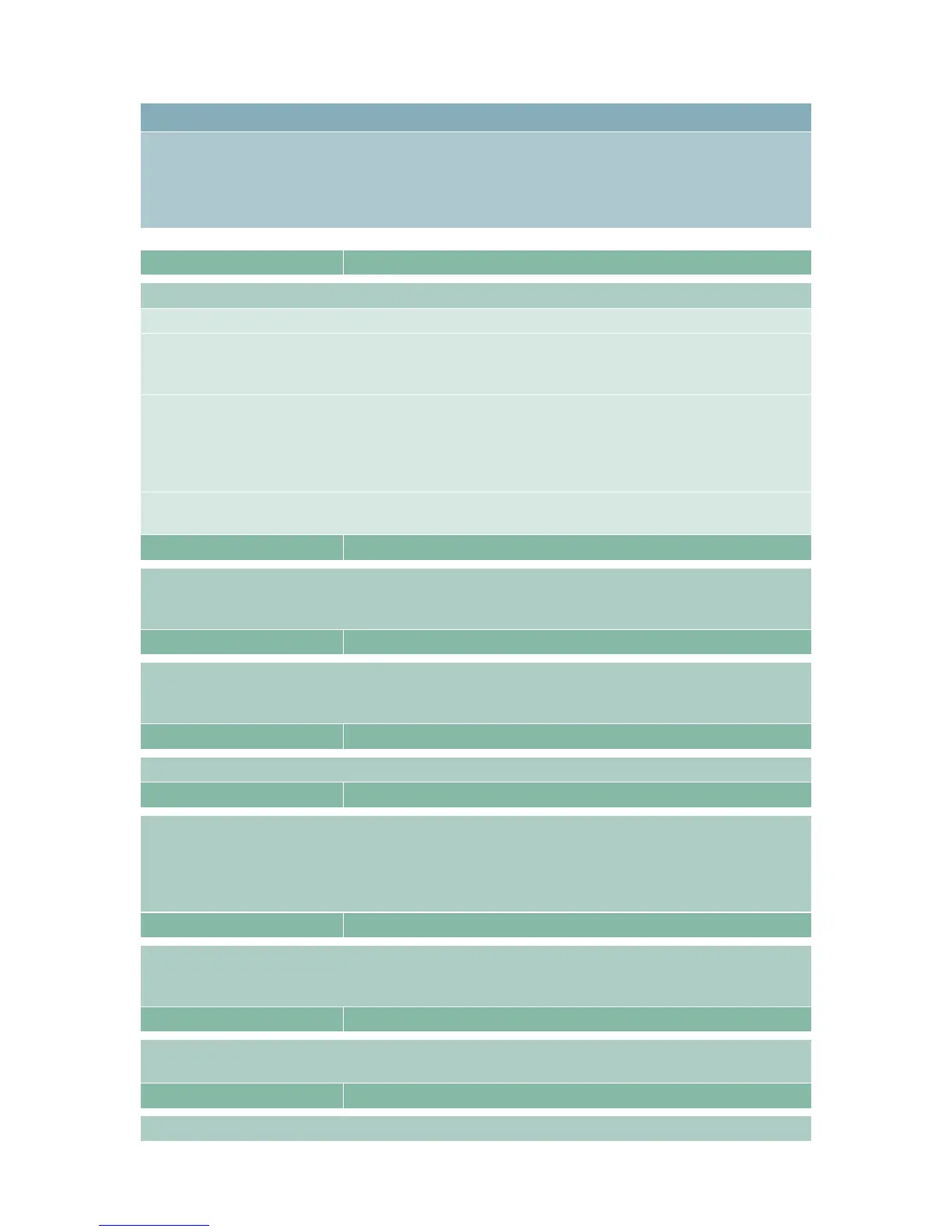

Specifies the analog input signals for the controller. Analog inputs are used to connect sensors like

thermocouples, resistors, voltage/current signals to the controller. You can exactly define signal type (voltage,

resistance, current) as well as signal range, signal conversion and correction, unit etc. The most common signal

types are predefined. Each column of the table defines one process value which are named IN00, IN01 etc. The

maximum number of analog input depends on the hardware.

(options END, T/C, LIN, ATMS, RES)

type of the analog input signal. Choose the appropriate kind of signal conversion from the given options:

T/C: Thermocouple input type. Selection of thermocouple and compensation mode see parameter below

LIN: Linear input type for generic use. This mode is used to convert any kind of linear input signal (as defined in

the corresponding parameters) into its process parameter. An example for a typical application is to convert a

4-20mA signal from a pressure transducer into 0 to 100 Pa process parameter

ATMS: Atmosphere signal conversion. Use this selection to convert the typical signal of a circonoxyde probe

into the kiln atmosphere reading. The controller uses the equation of Nerntzsch to convert the probe signal

into % of oxygen. The probe temperature required for oxygen calculation is specified in the corresponding

parameters as well as the kind of gas required for the carbonmonoxyde calculation. Note below on

temperatures below 650°C no oxygen calculation is done (no reliable probe signal)

RES: Resistance temperature sensor conversion. Converts the resistance characteristic of most commonly used

resistance sensors (like Pt100) into temperature reading

(value range AI0.0 to AI1.0)

Specifies a physical input (AI..) of the controller. The process parameter is created from the signal on this

physical input. To create two different process parameters from one physical input make sure that both signal

types and ranges equals

Specifies the low pass signal filter. This options is used to smoothen the input signal. Can be used to eliminate

signal interference as well as to improove signal quality. Setting this option to "1" disables the filter. A higher

setting causes higher smoothening (low pass frequency is 1/n Hz). A setting of 4 suits most applications.

(options °C, °F, °K, dg, mV, mA, O2, CO, %, ev, mb, m³, m³h, kh, kwh, Pa, AT)

Specifies the unit of the process value

(value range -10.0 to 10.0)

Allows full scale input signal correction. In certain applications it is required to compensate for any deviations

of the installation. Example: Setting this parameter to -5.0% will cause the process value to be trimmed to 95°C

instead of 100°C. Note: This parameter should be used with care since on most applications deviations errors

should to be compensated by eliminating the real cause of the deviation rather then compensating on the

controller

(value range -10.0 to 10.0)

Allows zero offset signal correction. Adjust this parameter if you need to adjust the input offset value. Note:

This parameter should be used with care since on most applications deviations errors should to be

compensated by eliminating the real cause of the deviation rather then compensating on the controller

(value range -9999 to 9999)

Minimum value of the process value. Specifies the lower value limit of the process parameter. Any lower value

is respected as underrun (causing an error)

(value range -9999 to 9999)

Maximum value of the process value. Specifies the upper value limit of the process parameter. Any higher

Loading...

Loading...