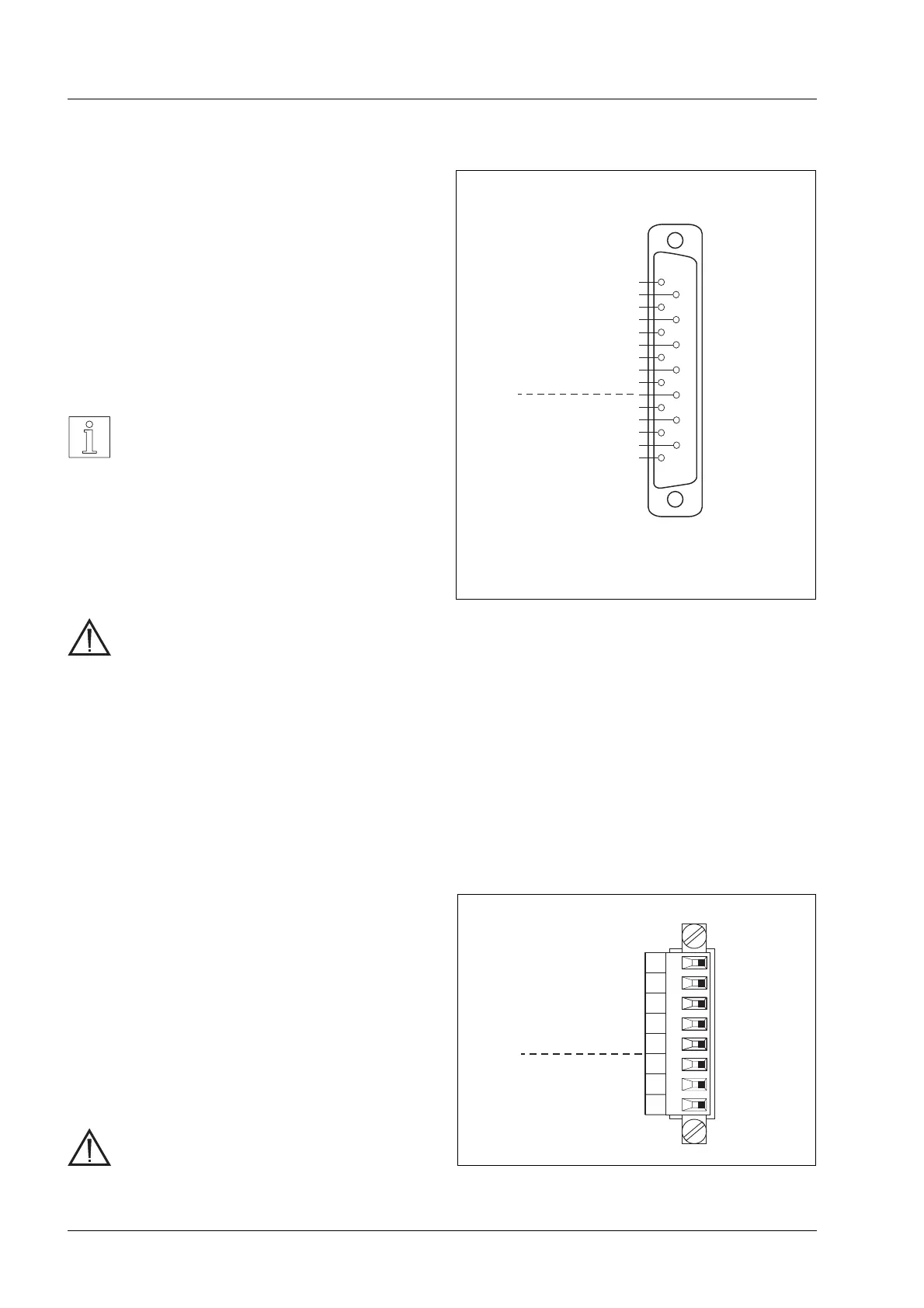

2.4.5 Connection of the signal cables

Signal cable of signal interface 1

1. Twist the wires of the signal cable for signal

interface 1 in pairs and solder to the terminals of

the 15-pole sub-D socket connector strip as

shown in Figure 2-8.

2. Insert cable underneath the strain relief clamp

and secure. Connect screen to earth (GND) on

control side.

NOTE

When using a push-pull drive, it may

be useful to connect the screen to the

plug shell on both ends of the cable.

3. Fit socket shell.

4. Plug socket to socket connector strip 07, and

screw tight.

CAUTION

•

For maximum cable length to signal

interface 1, see standard for RS 422

interfaces.

•

All signal connections must be safely

isolated from the mains.

•

The earth (GND) of signal interfaces

1 and 2 is connected internally to the

protective conductor.

•

It is not permitted to apply a voltage

between earth (GND) and protective

conductor in order to avoid damage.

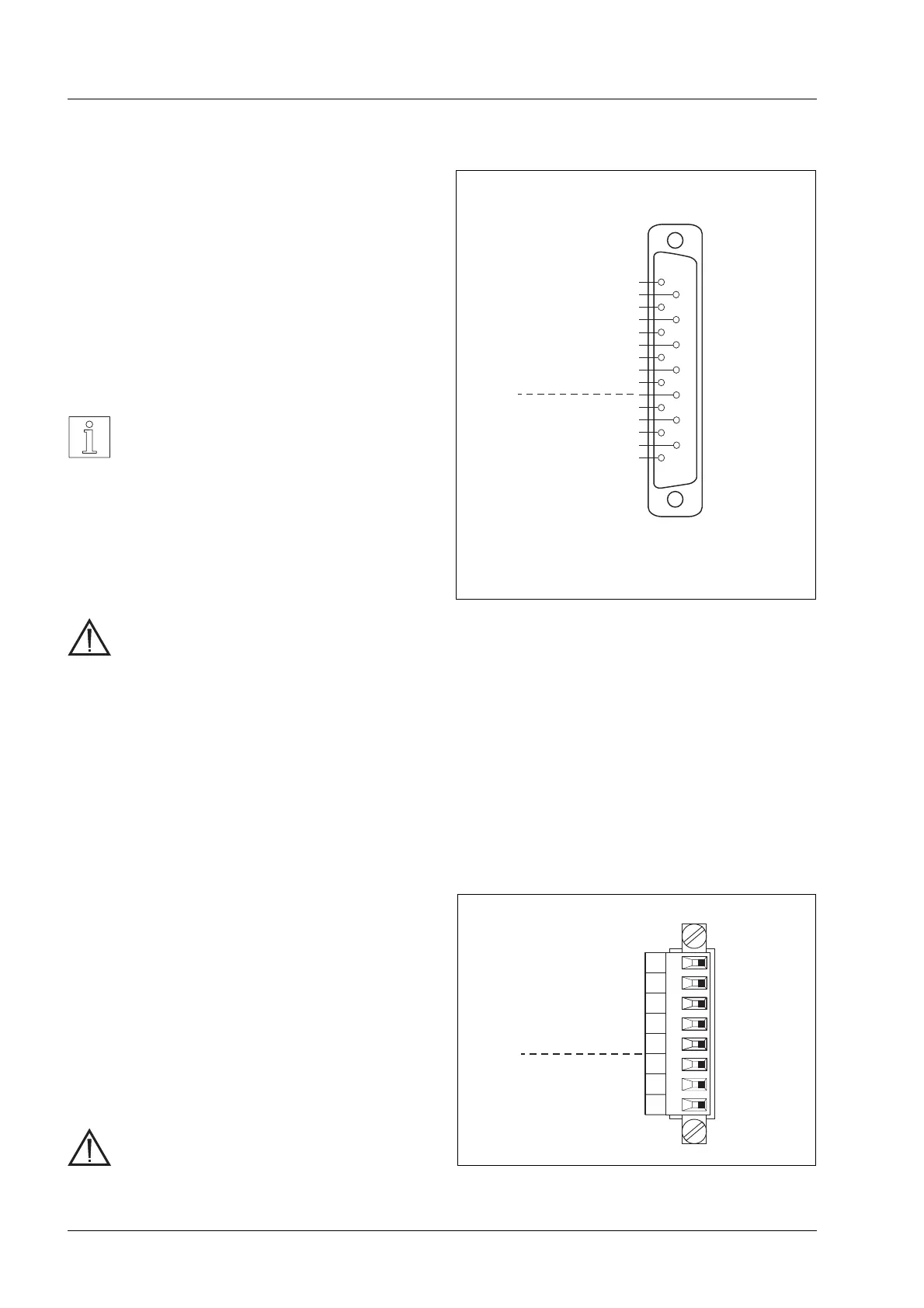

Signal cable of signal interface 2

1. Prepare the 8 wires of the signal cable for signal

interface 2 and fit to plug with boot lace ferrules.

2. Insert the wires into mating plug terminal block as

shown in Figure 2-9 and screw tight.

3. Join the plug shell halves together.

4. Fit plug to terminal 08 and screw tight.

CAUTION

•

Maximum length of signal cable:

50 m.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

PULSE

PULSE

DIRECTION

DIRECTION

ENABLE

ENABLE

PWM/BOOST

PWM/BOOST

GND

READY

READY

GND

READY*

+

-

+

-

+

-

+

-

+

-

07

OPEN COLLECTOR output (npn)

I

max

=10mA

U

CEsat

≤1.2V

(short-circuit-proofup to6 V)

*

InputsOutputs

Figure 2-8 Connector pin assignment for signal

interface 1

8

7

6

5

4

3

2

1

GND

READY

READY

ZERO PHASE

ZERO PHASE

PWM/BOOST

GATE

ENABLE

-

+

-

+

08

OutputsInputs

Figure 2-9 Connector pin assignment for signal

interface 2

Installation

2 – 6 WS5-5 Doc. no. 211.347/DGB 03.96

Loading...

Loading...