8 9

2 PRODUCT OVERVIEW

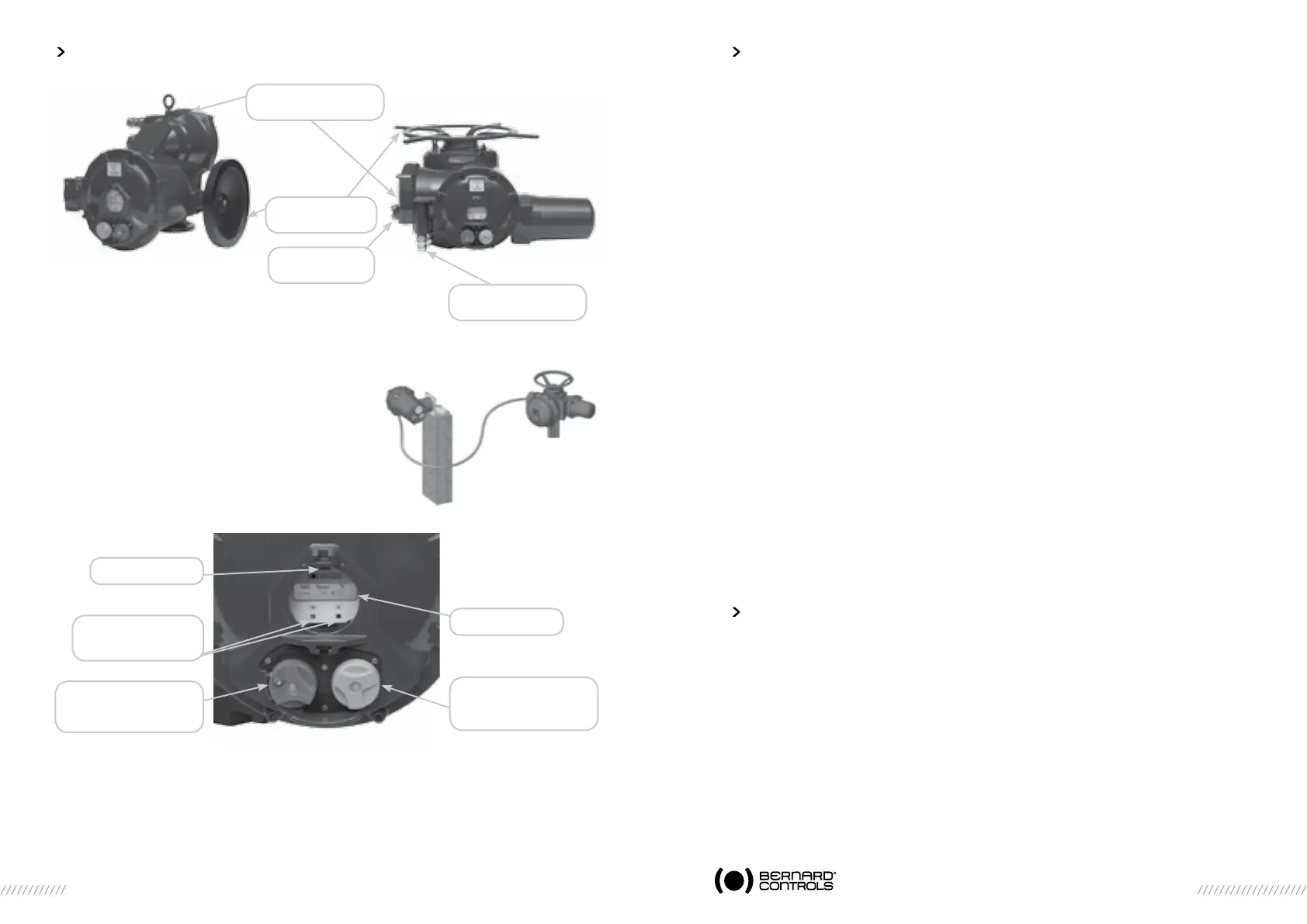

Manual override

All INTELLI+ actuators incorporate a handwheel for manual control with an automatic clutch system with

motor-drive priority. The direction of rotation is normally clockwise for closing unless otherwise specified.

Remote control box configuration

Emergency

handwheel

Blue selector

Open/Close &

Up-Down Scroll

display

Infrared port

Open & closed

valve indication

LEDs

Red selector

Local/Distance/Stop

& validation (OK)

Terminal

compartment

3 STORAGE

Introduction

An actuator consists of electrical components plus mechanical parts which have life-long lubrication.

Although the assembly is contained in a waterproof housing, the actuators may suffer from oxidation,

become clogged or seize during commissioning if it has not been stored correctly.

Storage

Actuators must be stored under cover in a clean, dry place which is protected against variations

in temperature.

Avoid storing directly on the ground. If stored in areas subject to damp, apply power to the actuator

to dry it out electrically. Check to ensure that the cable entries are sealed.

Ensure electrical component covers and compartments are properly sealed.

In case of a valve with an important stem lift, check that the stem protection cover is mounted

on the actuator. If not, assemble it with a weak sealing paste.

Inspection following storage

1. If stored for less than one year:

•Visualinspectionofelectricalparts.

• Operate buttons, selectors, etc. manually to ensure that they can be used without difficulty.

•Performafewmovementsmanually.

•Checkconsistencyofgrease.

•Commissiontheactuator.

2. If stored for more than one year:

• Long-term storage causes the consistency of the grease to change. To avoid any

grease-drying problem, do some rotations of the actuator several times a year by using

motor or manual override.

•Visualinspectionofelectricalparts.

• Operate buttons, selectors, etc. manually to ensure that they can be used without difficulty.

• For the actuators equipped with battery option. During the storage period, the circuit

is in low comsumption mode which allows to get a long lifetime of the battery. Beyond

a storage time of 3 years it is better to replace the batteries at the commissioning.

You can check the battery status at any time on the display.

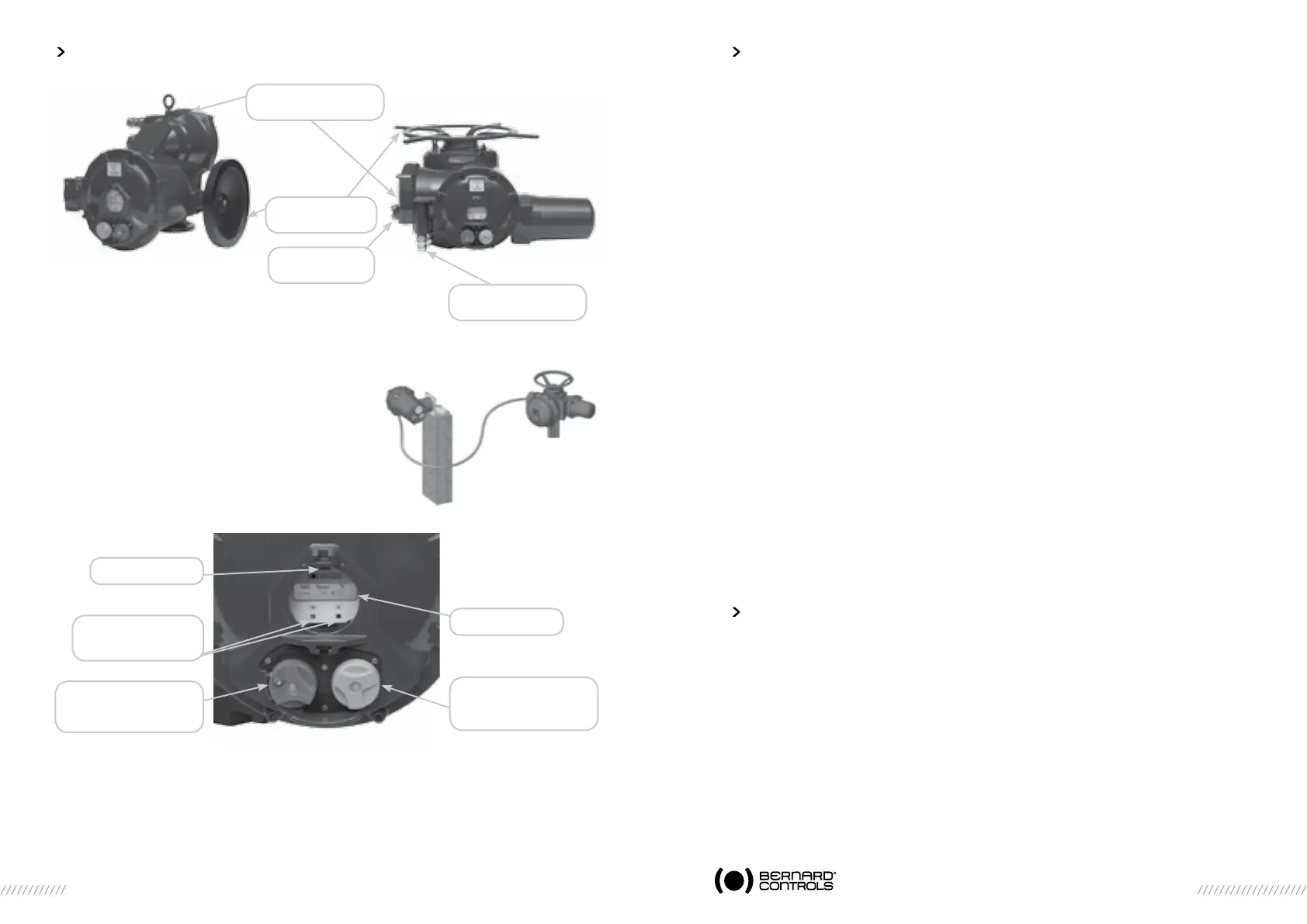

4 ACTUATOR ON VALVE ASSEMBLY

Actuator should be secured directly to the valve using proper bolts or via a proper interface.

After assembly, the actuator can operate in any position. However, cable glands should not be

oriented upwards (loss of water tightness) and the motor will preferably not be positioned at the

bottom (potential internal condensation trap)

Note 1: do not lift the actuator by handwheel, it could damage the wormwheel gear.

Note 2: see § 31 for details on storage precaution prior to starting-up.

Note 3: Greasing of A form drive bush has to be done prior to mounting actuator on valve (in the

case of a rising stem valve).

Fieldbus

connection

Power and hardwired

controls connection

Loading...

Loading...