KB-130-6 19

ter system and in low temperature applications requires

individual consultation with BITZER.

The use of the 2MTE-4K..6CTE-50K compressors

with motor version 1 as parallel compressors is pos-

sible. However, with regard to the lubrication condi-

tions, the gas suction superheat should not fall below a

minimum value of 10 K. The partial load range or the

switching to the operation with flash gas bypass is of

particular importance for the evaluation of the lubrica-

tion conditions. If necessary, a heat exchanger should

be used to minimise the refrigerant concentration in the

oil. Consultation with BITZER is recommended.

The use of compressors with motor version2 as paral-

lel compressors requires individual consultation with

BITZER.

Filter drier

The solubility of water in gaseous CO

2

is much lower

than in other refrigerants. This means that a relatively

small amount of moisture can freeze out of the refriger-

ant and block or clog the regulation valves, particularly

in low temperature applications. Therefore a gener-

ously sized filter drier and a sight glass with moisture

indicator for CO

2

are necessary. Observe the maximum

operating pressures of the filter driers! The application

may possibly be limited to the liquid line after the inter-

mediate pressure receiver or the suction side (for sys-

tems without intermediate pressure receiver).

4 Mounting

4.1 Vibration damper

The compressor may be rigidly mounted if there is no

danger of fatigue fractures in the pipeline system con-

nected to it. Otherwise the compressor must be moun-

ted on vibration dampers.

Mounting the suction gas and discharge gas lines:

• Mount compressor on the vibration dampers or ri-

gidly. In this position (= operational position), con-

nect the suction gas and discharge gas lines and

make sure that they are stress-free. For a selection

of the vibration dampers see table 2, page 19.

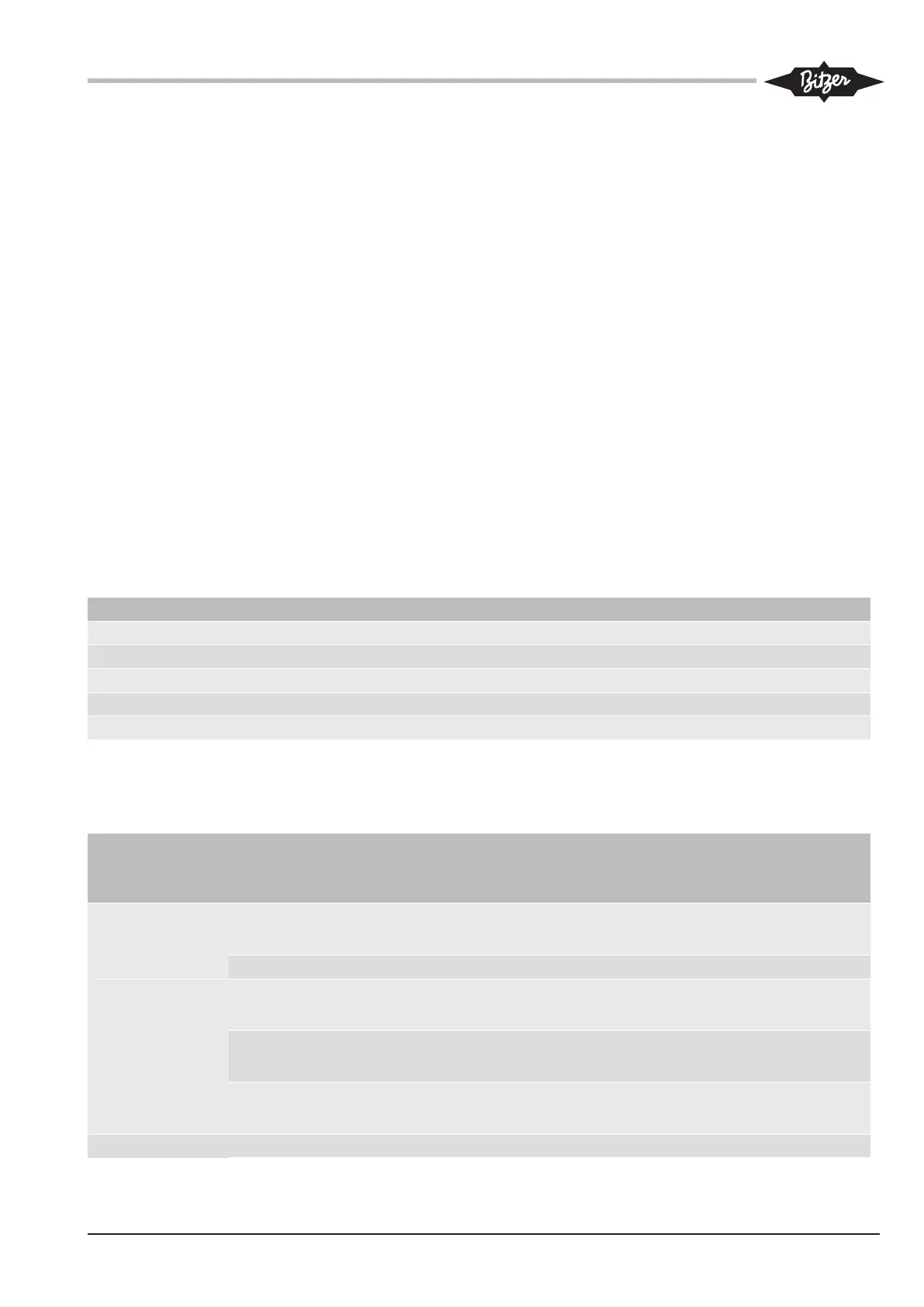

Compressor Kit number, article number (4pieces) Hardness

2MTE-4K .. 2KTE-7K 370 005 02 60 Shore

4PTC-6K .. 4KTC-10K 370 005 02 60 Shore

4JTC-10K .. 4CTC-30K 370 005 03 55 Shore

6FTE-35K .. 6CTE-50K 370 005 03 55 Shore

4PTC-7.F3K .. 4KTC-10.F4K 370 000 20 55 Shore

Tab.2: Vibration dampers 2MTE-4K .. 6CTE-50K and 4PTC-7.F3K .. 4KTC-10.F4K

4.2 Shut-off valves / weld connections

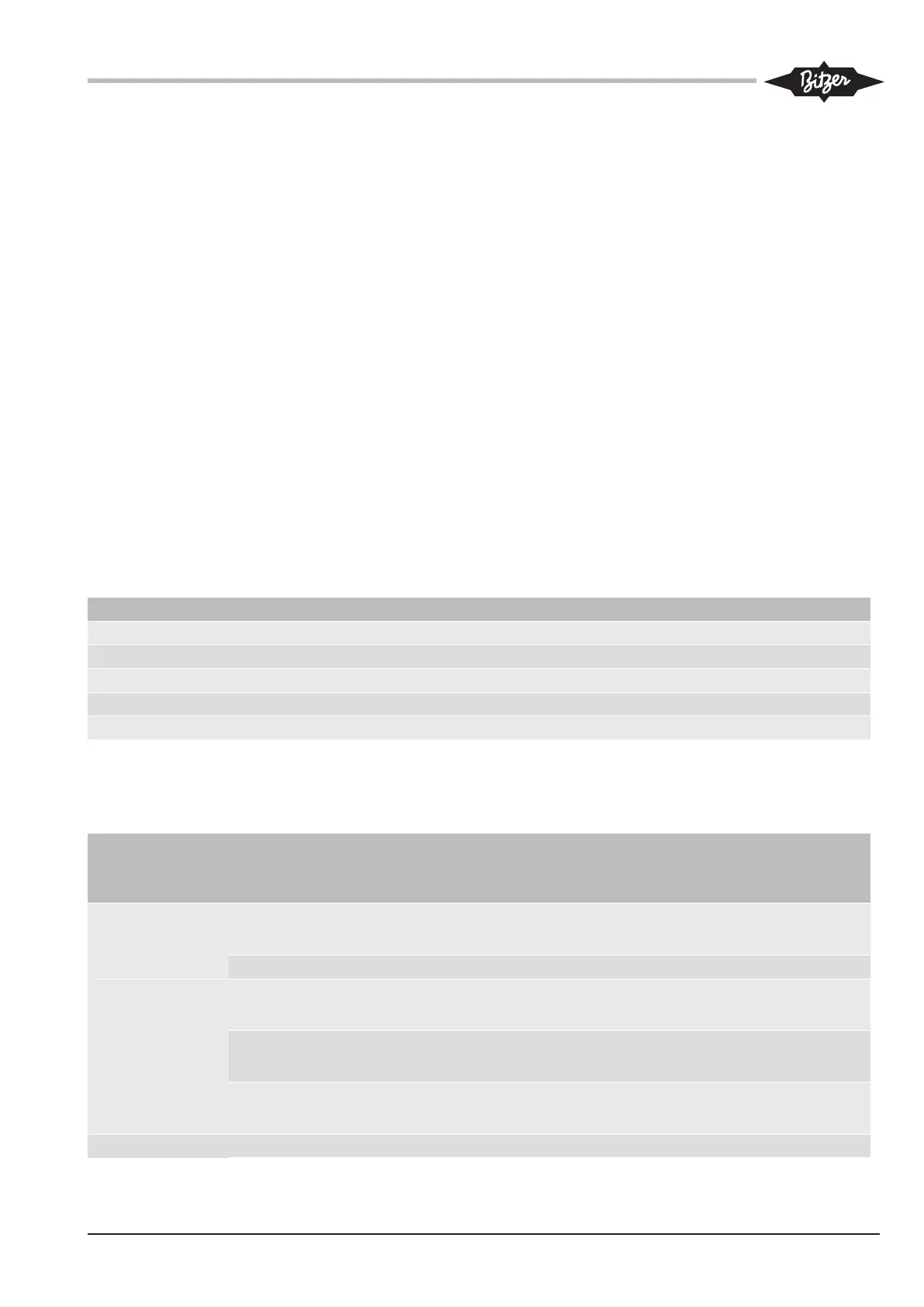

Compressor Shut-off valve article no. Designation Inside diameter

d

i

Outside dia-

meter d

a

2MTE..2KTE

4PTC..4KTC

36136718 "Brazed/welded connection"

Ø19..25.4

19mm 25.4mm

36136719 Swagelok valve 18mm 18mm Swagelok

4JTC..4CTC 36136720 "Brazed/welded connection"

Ø10.1..14

10.1mm 14mm

36136721 "Brazed/welded connection"

Ø16.1..22

16.1mm 22mm

36136723 "Brazed/welded connection"

Ø22.4..30

22.4mm 30mm

6FTE..6CTE 36136722 Swagelok valve 28mm 28mm Swagelok

Loading...

Loading...