SB-170-9 RUS

9

SB-170-9 25

5

.4.2 CM-SW-01

Standard for all CSW105 compressors

The compressor module integrates the entire electronic

periphery of the compressor: It allows monitoring the

essential operating parameters of the compressor: mo-

tor and discharge gas temperature, phase and rotation

direction monitoring, oil supply and application limits

and thus protects the compressor from operation under

critical conditions. For further information, see Tech-

nical Information ST-150.

NOTICE

The compressor module may be damaged or

fail!

Never apply any voltage to the terminals of CN7

to CN12 – not even for test purposes!

The voltage applied to the terminals of CN13

must not exceed 10V!

The voltage applied to terminal 3 of CN14 must

not exceed 24V! Do no apply voltage to the

other terminals!

The following components are completely installed and

wired in the state of delivery:

• Slider position indicator.

• Oil monitoring (OLC-D1).

• Solenoid valves for capacity control and V

i

.

• Discharge gas temperature sensor.

• Low pressure and high pressure transmitter.

Modification to these components or their wiring is not

required and should not be done without consulting

BITZER.

The following components are not installed and wired in

the state of delivery and need to be connected:

• Motor temperature monitoring (PTC sensor in motor

winding).

• Phase monitoring (in case of a phase failure or inad-

missibly high phase asymmetry).

The compressor module internally supplies voltage to

the peripheral devices (solenoid valves, oil monitoring

device and slider position indicator) and to the terminal

strips CN7 to CN12.

Please refer to the Technical Information ST-150 for in-

formation on all connections.

5

.4.3 SE-i1

This protection device with extended monitoring func-

tions can be used as an option for all HS.53 .. HS.85

compressors and CSH and CSW compressors.

Monitoring functions:

• Temperature monitoring.

• Monitoring of the PTC control circuit to detect any

short-circuit or line break/sensor failure.

• Rotation direction monitoring.

• Monitoring of phase failure and asymmetry.

• Monitoring of the maximum cycling rate.

For further information, see Technical Information

CT-110.

5

.4.4 SE-E2

Optional protection device for operation with frequency

inverter and soft starter (for a ramp time shorter than

1s).

• Dimensions and integration in the control identical to

SE-E1.

• Suitable for all CS. compressors.

• Monitoring functions are basically identical to those

of SE-E1. However, the SE-E2 monitors phase fail-

ure during the entire running time of the compressor.

For further information, see Technical Information

ST-122.

5

.4.5 Monitoring of the oil circuit

• For short circuits without liquid injection (LI) for addi-

tional cooling and for small system volume and small

refrigerant charge: Indirect monitoring with oil tem-

perature sensor (standard)

NOTICE

Lack of oil leads to a too high increase in tem-

perature.

Risk of damage to the compressor!

• For circuits with liquid injection (LI) for additional

cooling and / or for great system volume as well as

parallel compounding: Monitor oil level directly with

opto-electronic oil level monitoring (option), see

chapter Opto-electronic oil level monitoring OLC-D1-

S, page 26. The connection is on the compressor

housing, see chapter Connections and dimensional

drawings, page 14, position 8.

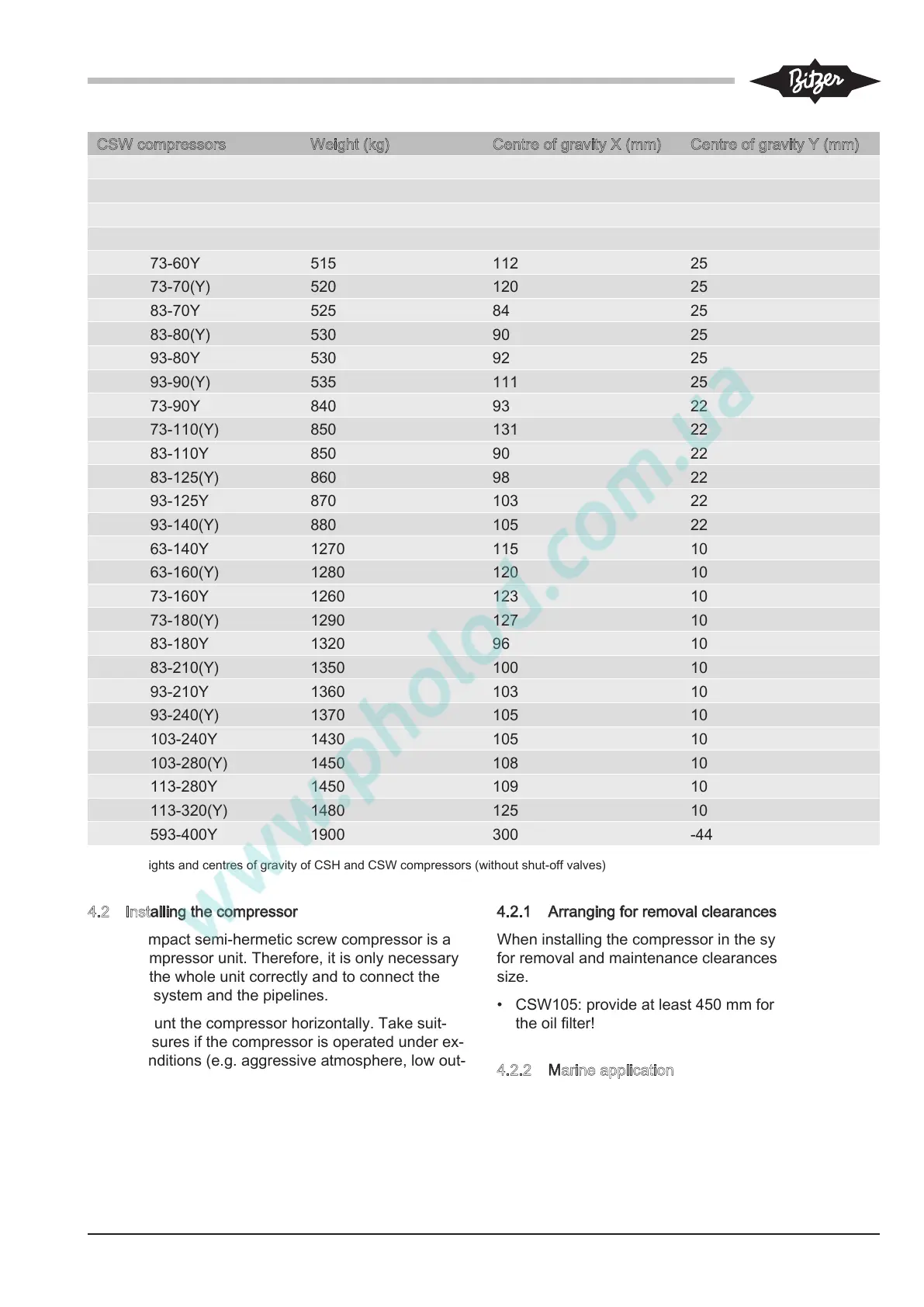

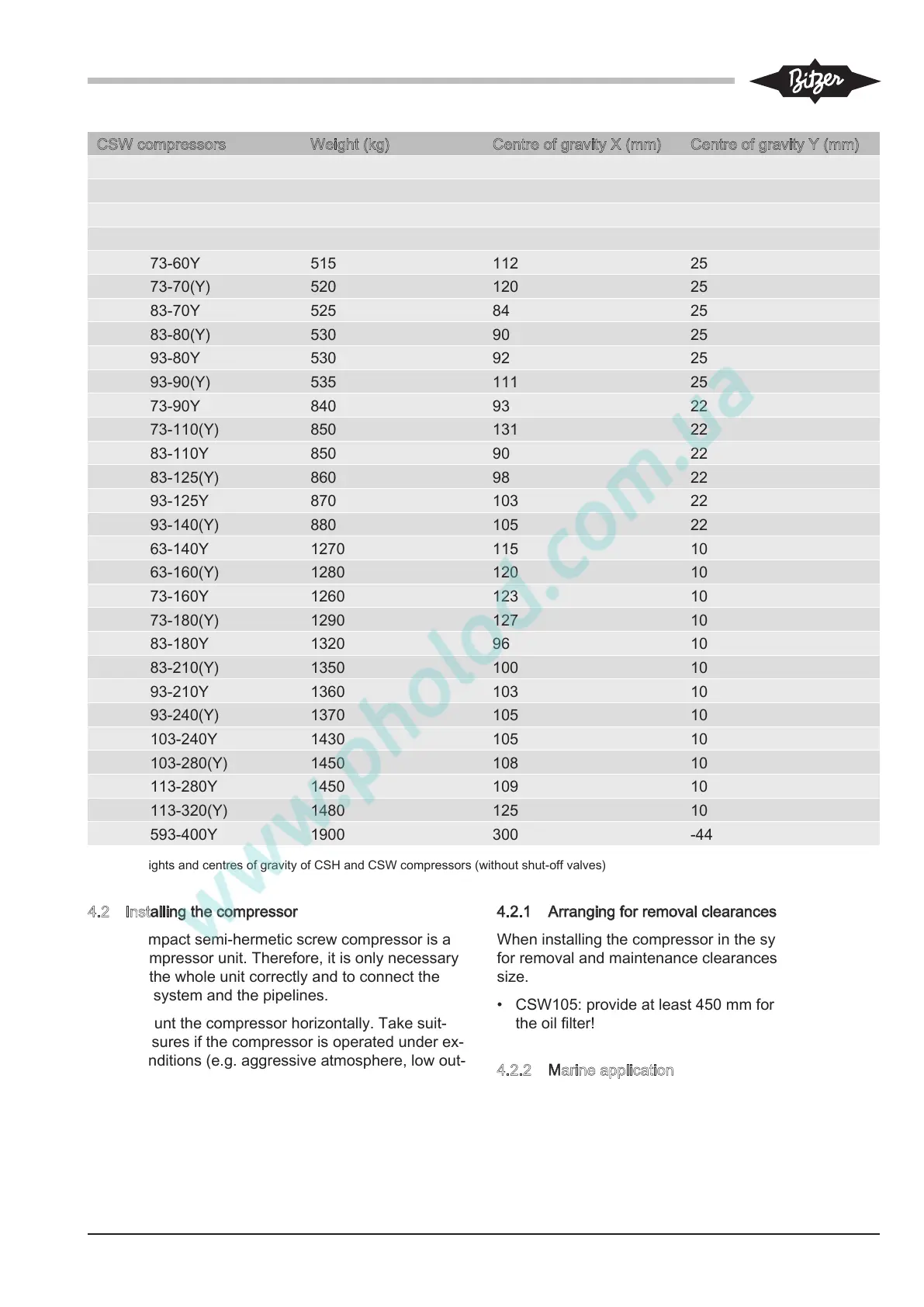

CSW compressors Weight (kg) Centre of gravity X (mm) Centre of gravity Y (mm)

CSW6583-40Y 360 34 22

CSW6583-50(Y) 365 39 22

CSW6593-50Y 360 42 22

CSW6593-60(Y) 365 46 22

CSW7573-60Y 515 112 25

CSW7573-70(Y) 520 120 25

CSW7583-70Y 525 84 25

CSW7583-80(Y) 530 90 25

CSW7593-80Y 530 92 25

CSW7593-90(Y) 535 111 25

CSW8573-90Y 840 93 22

CSW8573-110(Y) 850 131 22

CSW8583-110Y 850 90 22

CSW8583-125(Y) 860 98 22

CSW8593-125Y 870 103 22

CSW8593-140(Y) 880 105 22

CSW9563-140Y 1270 115 10

CSW9563-160(Y) 1280 120 10

CSW9573-160Y 1260 123 10

CSW9573-180(Y) 1290 127 10

CSW9583-180Y 1320 96 10

CSW9583-210(Y) 1350 100 10

CSW9593-210Y 1360 103 10

CSW9593-240(Y) 1370 105 10

CSW95103-240Y 1430 105 10

CSW95103-280(Y) 1450 108 10

CSW95113-280Y 1450 109 10

CSW95113-320(Y) 1480 125 10

CSW10593-400Y 1900 300 -44

Tab.2: Weights and centres of gravity of CSH and CSW compressors (without shut-off valves)

4.2 Installing the compressor

Every compact semi-hermetic screw compressor is a

motor-compressor unit. Therefore, it is only necessary

to install the whole unit correctly and to connect the

electrical system and the pipelines.

Install/mount the compressor horizontally. Take suit-

able measures if the compressor is operated under ex-

treme conditions (e.g. aggressive atmosphere, low out-

side temperatures, etc.). Consultation with BITZER is

recommended.

4

.2.1 Arranging for removal clearances

When installing the compressor in the system, arrange

for removal and maintenance clearances of sufficient

size.

• CSW105: provide at least 450 mm for the removal of

the oil filter!

4

.2.2 Marine application

With regard to marine applications, defined diagonal

mounting on the longitudinal axis of the ship can be ne-

cessary, see figure 3, page 10.

Loading...

Loading...