GAS CONVECTION OVENS 7 INSTALLATION

VENTILATION

DIRECT FLUE ARRANGEMENT

When the installation of a mechanically driven exhaust hood is impractical the oven may be vented by a direct ue arrange-

ment.

WARNING!!

It is essential that the direct ue be installed as follows. Incorrect installation will result in unsatisfactory

baking and oven damage.

The ue must be class B or better. The height of the ue should rise 6-8 ft (2-2.5 m) above the roof of the building or any

proximate structure. Never direct vent the oven into a hood. The ue should be capped with a UL Listed type vent cap to

isolate the unit from external environmental conditions.

The direct vent cannot replace air consumed and vented by the oven. Provisions must be made to supply the room with

sufcient make-up air. Total make-up air requirements for each oven section should be approximately 30 CFM (.85 m3) per

section. To increase the supply air entering the room, a ventilation expert should be consulted.

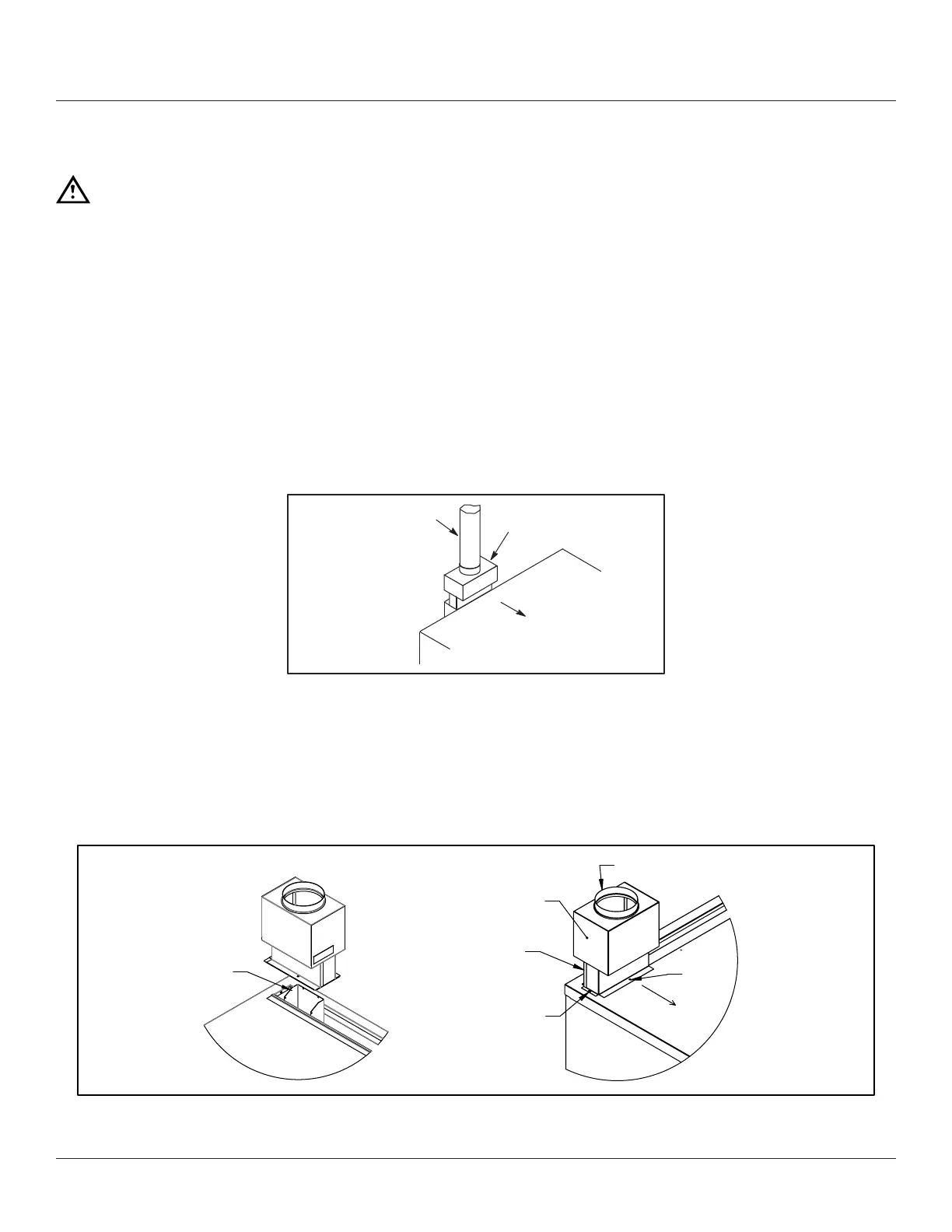

Installing the draft hood

Ovens ordered for direct venting are supplied with a draft hood. Install the draft hood as follows:

1. Place the draft hood over the ue connector.

2. Secure both ends with the sheet metal screws provided.

Front of Oven

Draft Hood

Flue

Figure 7

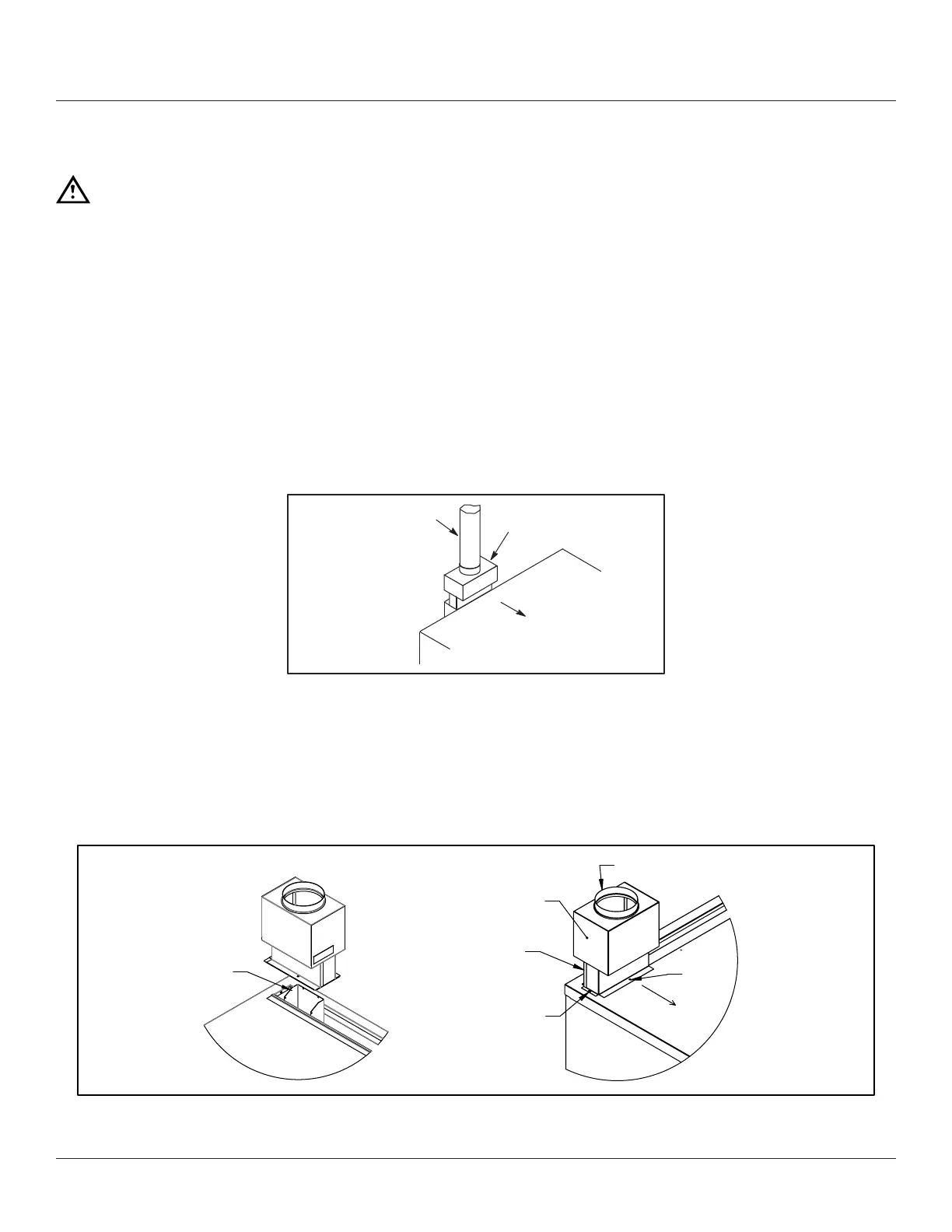

ES Models

1. Install draft diverter using the screws provided as shown below.

2. Place the draft hood over the draft diverter.

3. Secure both ends with the sheet metal screws provided.

Flue

Drafthood

Front of

Oven

Two screws

in back

One screw

into frame

One

screw

Draft diverter

Figure 8

Loading...

Loading...