Blue Box - 26

4. INSTALLATION

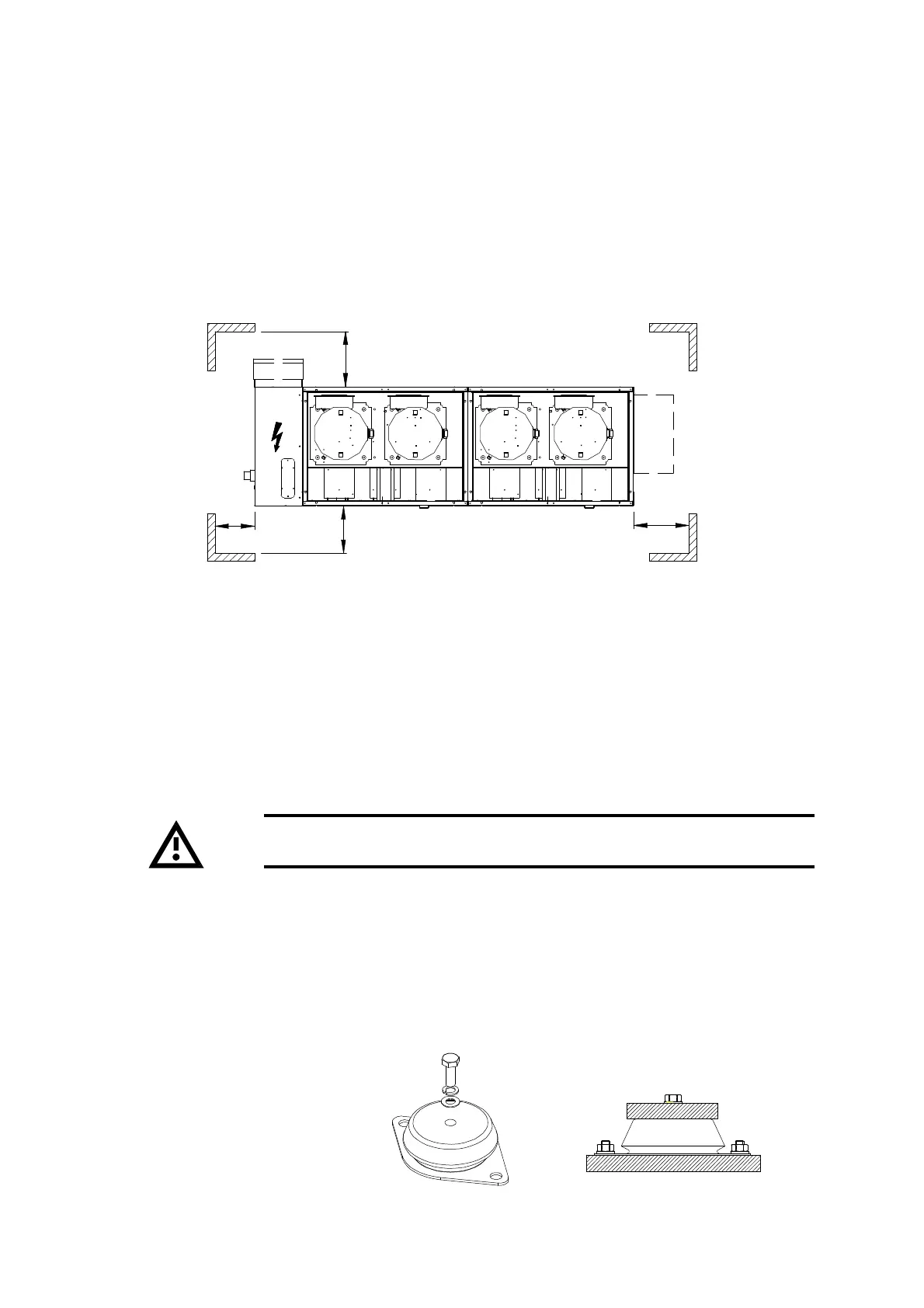

4.1 CLEARANCES

Minimum clearances for all units should be as follows:

- Long side: 800 mm to allow hydraulic connection to the system and servicing operations;

- Front side: 800 mm to allow access to electric board;

- Rear side: 800 mm to allow maintenance operations;

- Above the unit: 1000 mm.

Figure 3

Figure 4

800

800

800

800

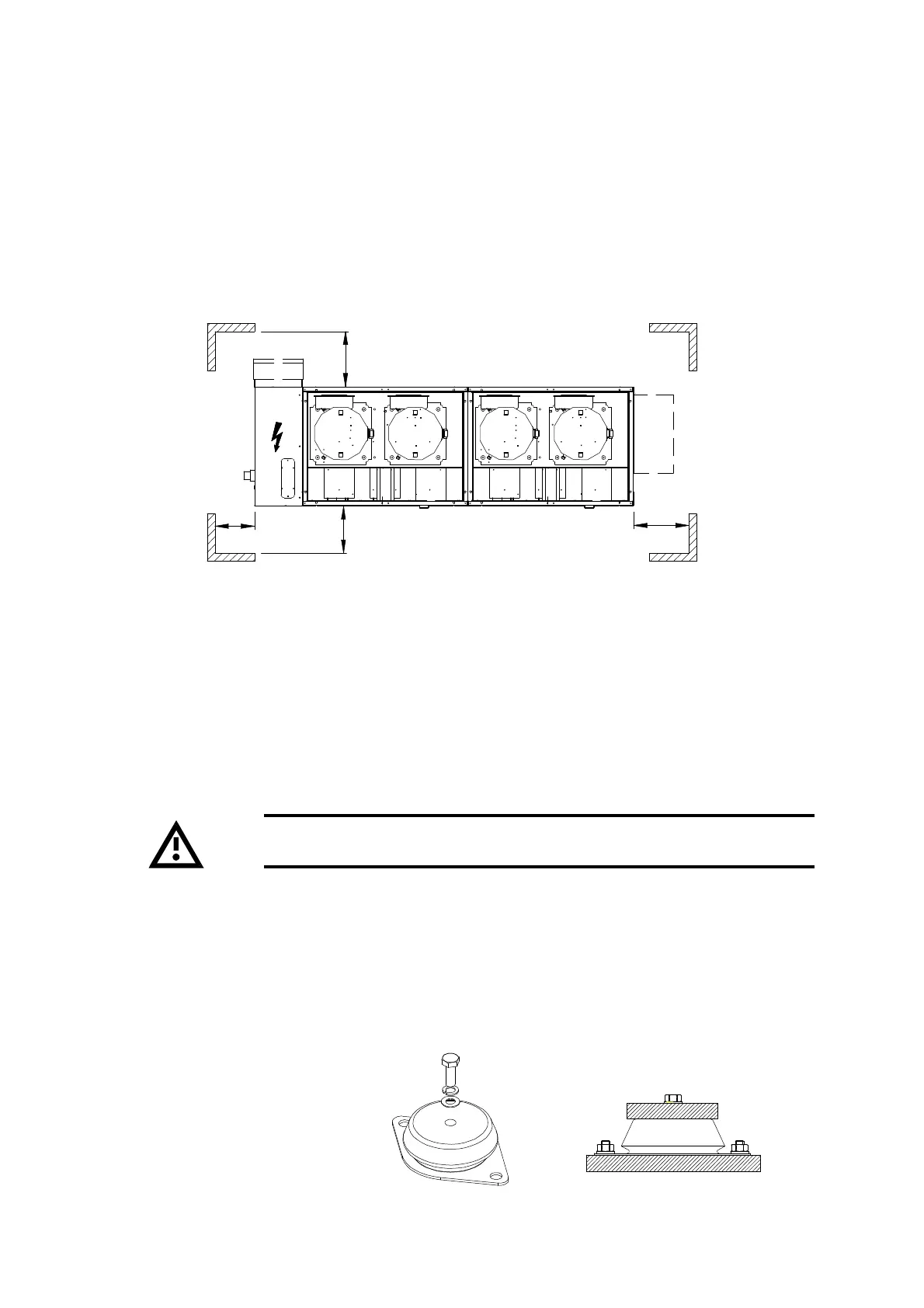

4.2 ANTI-VIBRATION ISOLATORS (option)

It is recommended that the unit is installed on rubber or spring anti-vibration mountings, supplied as an option, to

reduce vibrations transmitted to the building structure. It is advisable to use rubber isolators for units installed in

the basement, or ground floors in contact with the earth, and spring isolators for units installed on intermediate

floors.

The anti-vibration isolators must be installed before the unit is positioned.

Ensure that during lifting the unit is firmly secured with straps.

4.2.1 Rubber Anti-Vibration Isolators

Rubber isolators are made of an upper metallic bell with a fixing screw to the base-frame of the unit. The isolator

is fixed at the foundation via 2 holes on the flange. On the flange there is a number (45, 60, 70 ShA) which

identifies the hardness of the rubber isolator. The dimensional drawing, enclosed in the machine, shows the unit

footprint with the position and weight of each isolator.

Rubber/metal anti-vibration

isolator

Designed to reduce the vibration.

Loading...

Loading...