Blue Box - 89

12. MAINTENANCE AND PERIODIC CHECKS

12. 1 WARNINGS

All operations described in this chapter MUST BE PERFORMED

EXCLUSIVELY BY QUALIFIED PERSONNEL.

Make sure that the unit has been disconnected from the power supply

before carrying out any work or accessing internal parts.

The compressor head and discharge pipeline can reach high temperatures.

Always exert caution when working in the vicinity of the compressor.

12.2 INTRODUCTION

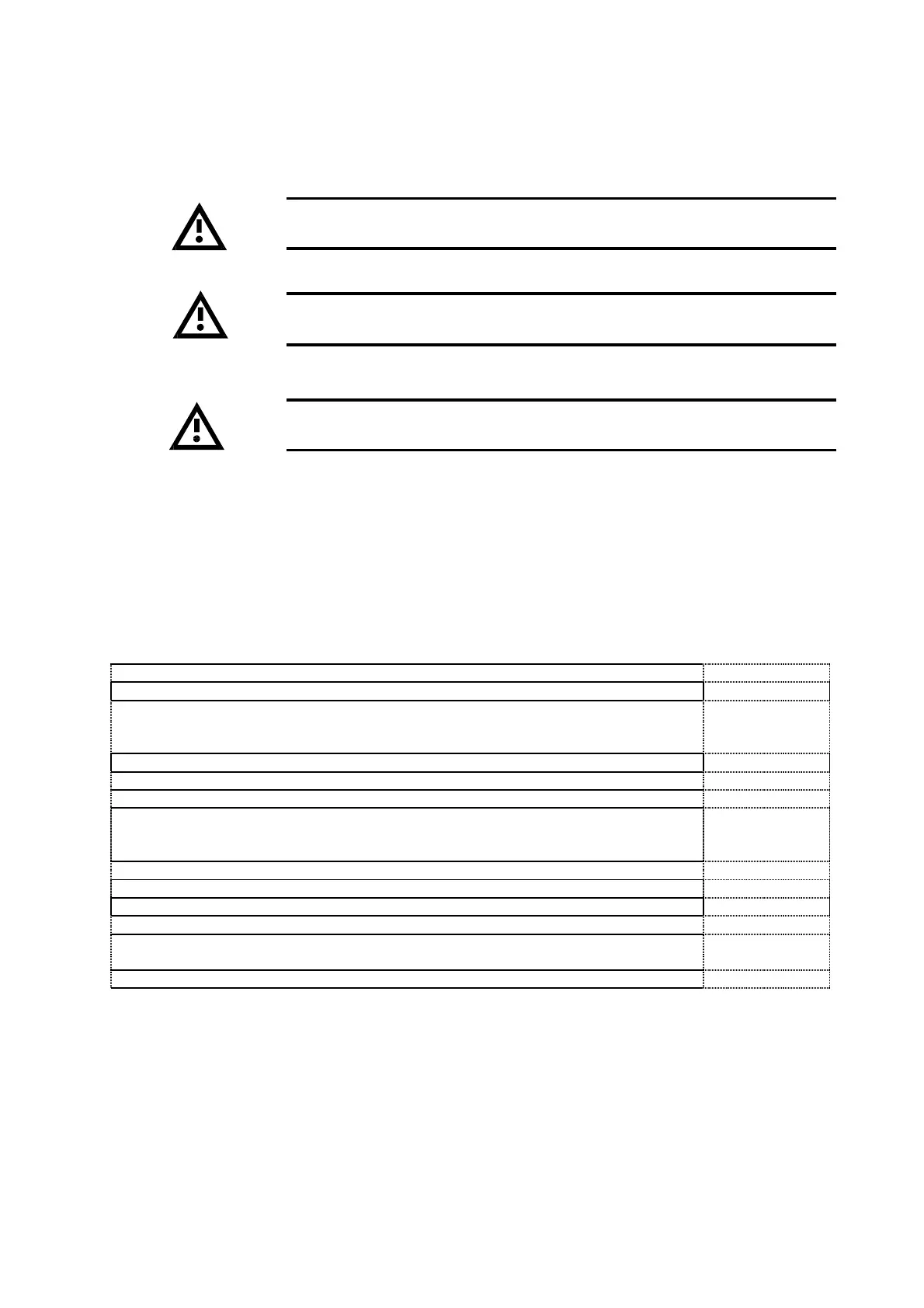

Carry out the following periodic checks to ensure the unit is operating correctly:

CHECK PERIOD

Check that safety and control devices work correctly as previously described monthly

Check all the terminals on electric board and compressor are well locked. Periodic

cleaning of the sliding terminals of the contactors should be done: if any damage is

found, replace the contactors

monthly

Check the sight glass to verify the refrigerant charge. monthly

Check there is no oil leakage from compressor monthly

Check there is no water leakage in the hydraulic system monthly

If the unit is to be stopped for a long period the hydraulic circuit, including all pipes and

heat exchangers, should be drained. This is compulsory if the ambient temperature is

expected to fall below the freezing point of the liquid employed.

seasonal

operation

Check process water levels monthly

Check that the flow switch is operating correctly. monthly

Check that the crankcase heater operating correctly and the power supply. monthly

Clean metallic filters on water piping monthly

Check the colour of the sight glass core (green = no moisture, yellow = moisture

present): if it has a yellow colour, change the refrigerant filter

every 4 months

Check that the noise level has not increased. every 4 months

Loading...

Loading...