BOGE Operating instructions for C 10 L...C 20 L series screw compressors Page 41

Maintenance 5.3 Regular maintenance work

– Close ball valve at the compressed air outlet.

– Open safety sound insulation hood.

– Vent the compressor (as described in the beginning of the chapter).

– Wait approx. 3 minutes to permit the oil to settle.

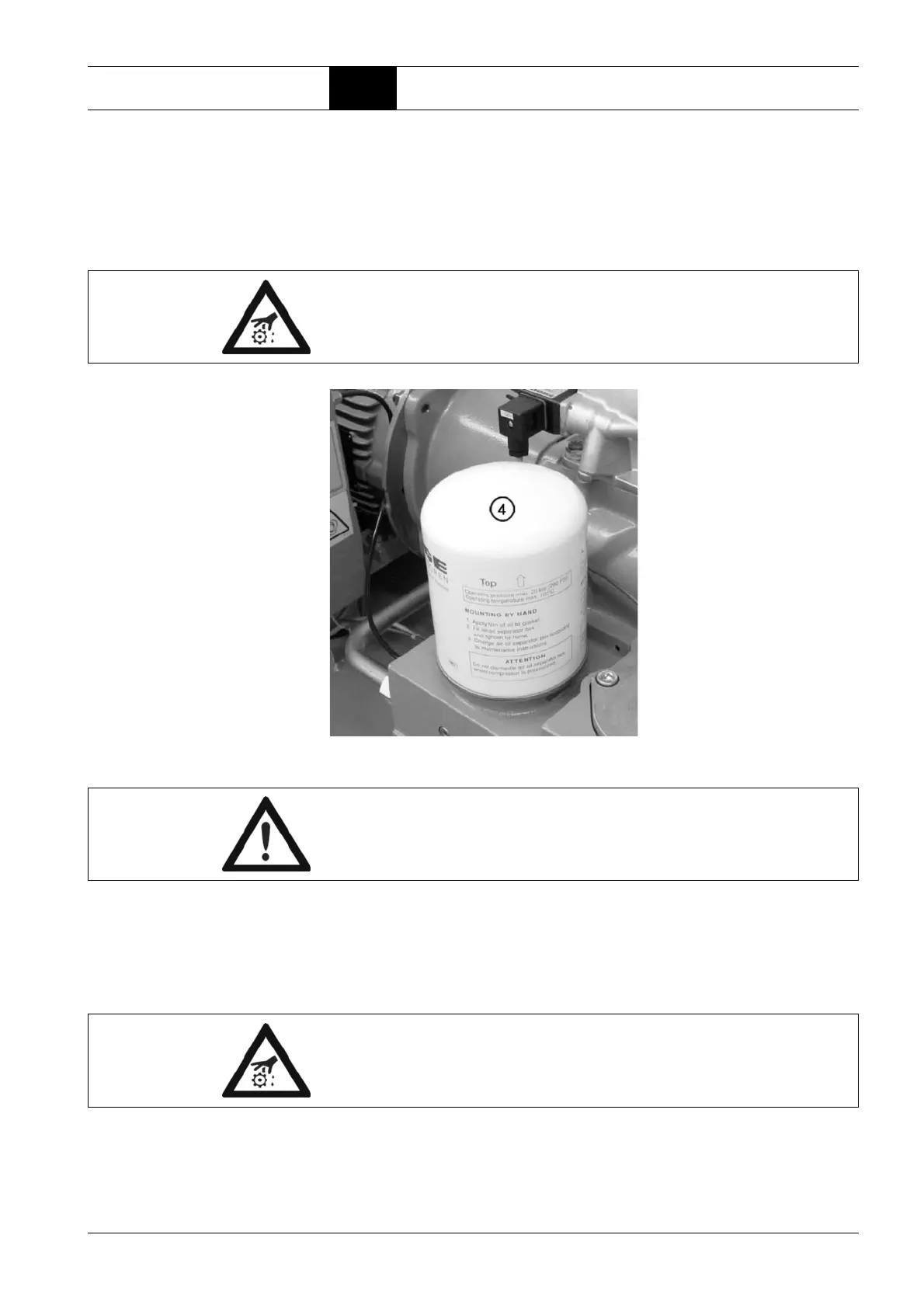

Fig. 5.5: Changing the oil separators

– Open ball valve at the compressed air outlet.

– Switch on the compressor and heat up to operating temperature.

– Check the oil separators for leaks once again (procedure as described

above).

– Check the oil separators for leaks and tighten by hand, if necessary.

Caution: Risk of injury!

Danger of burning due to hot oil!

Always wear safety gloves!

– Remove cladding from

the service side.

– Unscrew soiled oil sepa-

rators (4) by hand or use

a strap wrench, turning

counterclockwise.

– Catch the draining oil and

dispose of properly ac

-

cording to environmental

regulations.

– Lightly oil the sealing

rings of the new oil sepa

-

rator.

– Screw in new oil separa-

tors (4) by hand, turning

clockwise.

Attention!

Do not use tools to screw in the new oil separators!

You might damage the oil separators or their sealing rings.

A hand tight seating of the oil filter is sufficient.

Caution: Risk of injury!

Press Emergency Stop button, open mains disconnection device and secure

against unintentional switch on by means of a padlock.

Loading...

Loading...