BOGE Operating instructions for C 15 series screw compressors Page 47

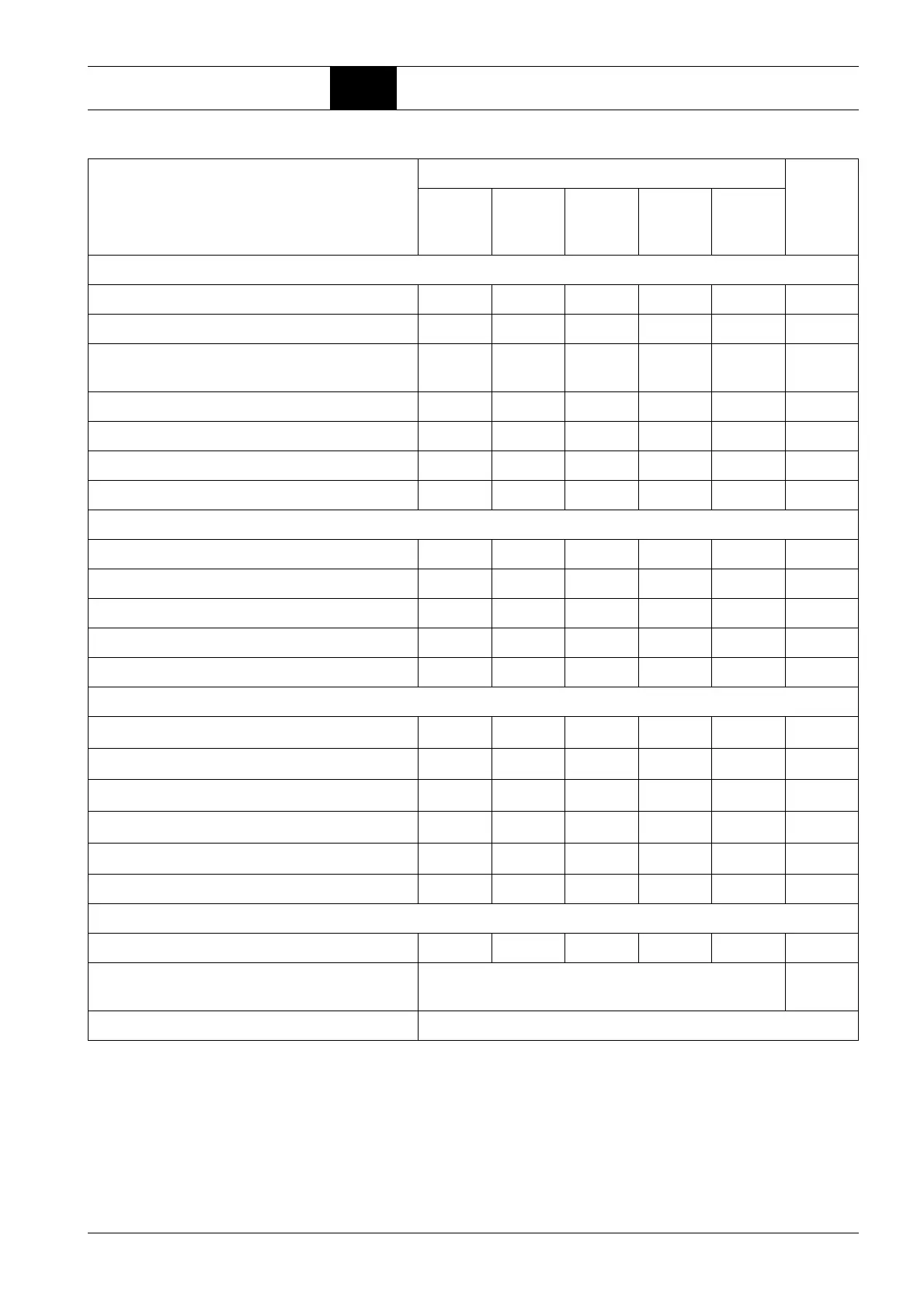

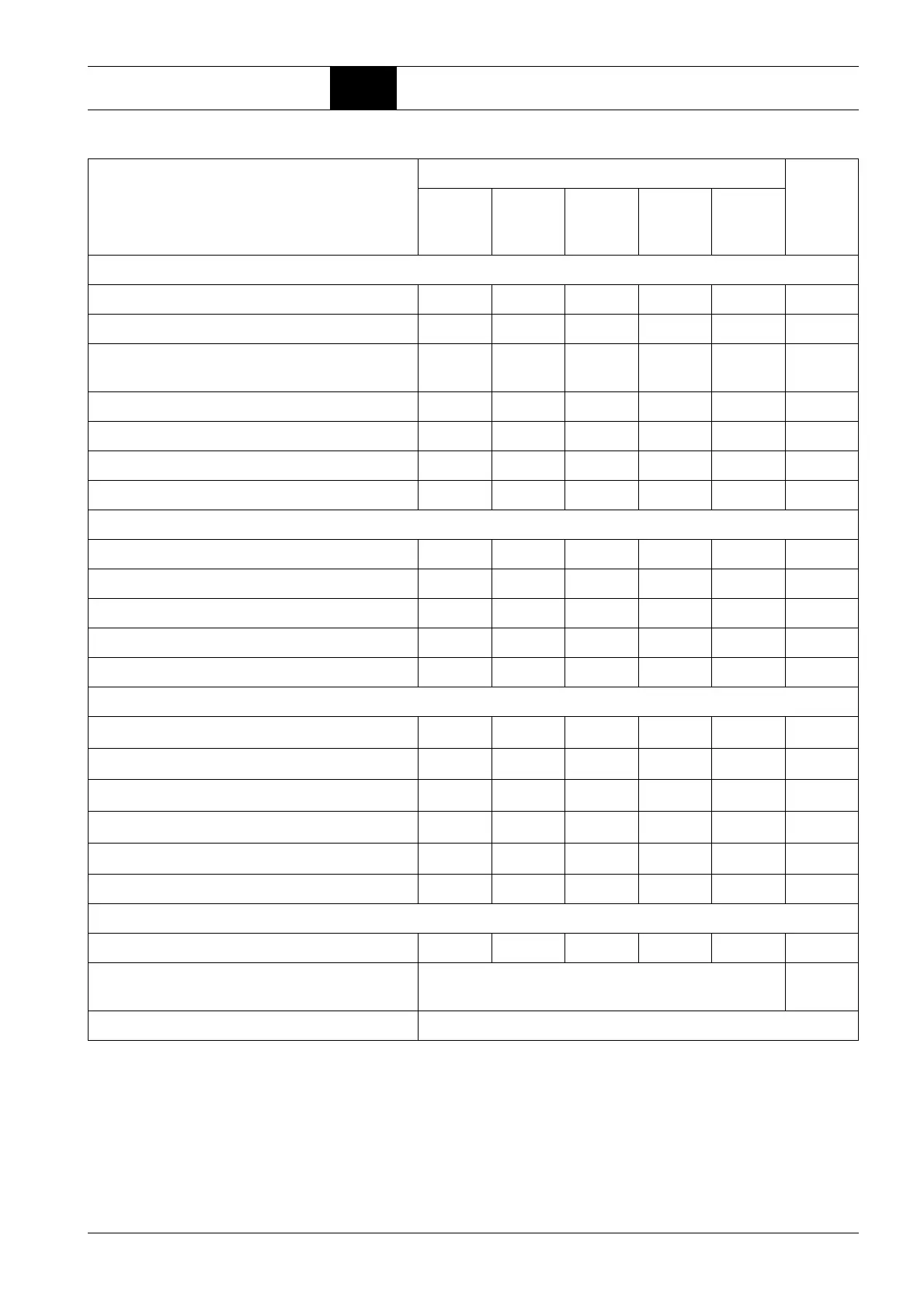

Maintenance 6.2 General

Maintenance work Maintenance intervals in operating hours

1)

Page

weekly,

monthly

1000

annually

1500

annually

3000

annually

9000

every

2 years

General maintenance work

Check final compr. temp. (set point value: 158...212°F) w Control

Check compressor for leaks X –

Check system relief on system pressure gauge (22)

(set point value: 0 – 22 psig)

w Control

Check function of emergency-stop switch/button m Control

Cleaning the oil cooling unit X 60

Check or change supply filter w 51

Check if electrical connections are tightened X –

Air circuit

Check and if necessary clean suction filter m 50

Change suction filter cartridge X 50

Check safety valve X 60

Replace minimum pressure valve (wearing parts set) X –

Replace suction controller X–

Oil circuit

Check oil level and top up as required

2)

m54

Change oil separator

2)

X56

Change oil filter

2)

X55

Change oil

2)

X57

Replace oil regulator (wearing parts set)

2)

X–

Replace nozzle with dirt catch X 61

Drive

Check/replace V-belt X 52

Lubricate drive motor bearings Drive motors with permanent lubrication:

Change when replacing the motor bearings

52

Replace motor bearing 20000 operating hours

1)

If the compressor is not often used, undertake the maintenance according to the specified intervals (weekly/monthly/annually) depending on the number of operating

hours.

2)

The specified intervals only apply when BOGE compressor oil Syprem 8000 S is used! The service life may differ depending on the ambient temperature. In this case

have the oil analyzed by your BOGE service!

Tab. 6.1: Maintenance intervals

Loading...

Loading...